Furnace controls, Staged burner adjustments, Staged temperature controls performance data – Greenheck Fan PVF User Manual

Page 5

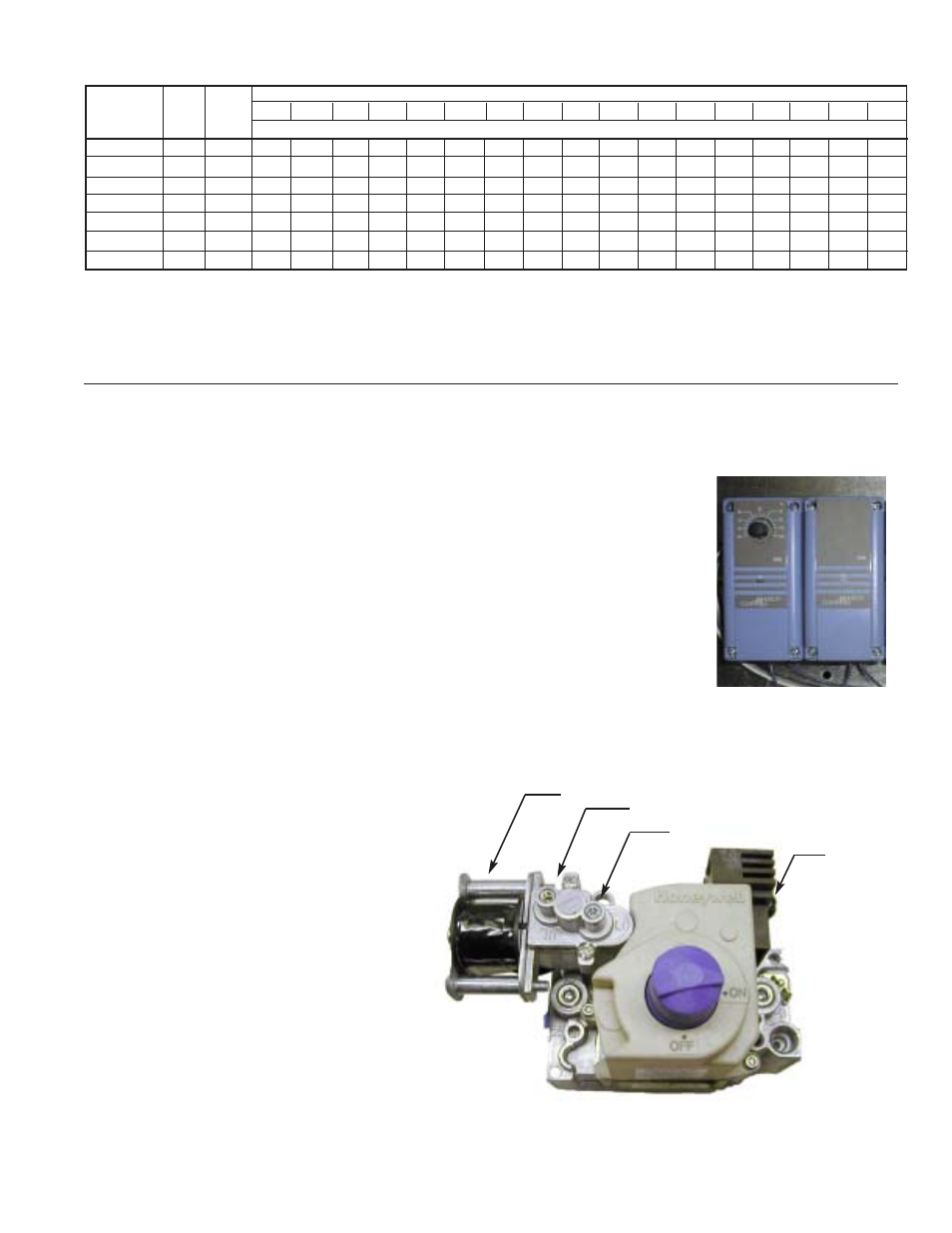

Setting Manifold Pressure for Two Stage Gas Control

1. Set the unit to high fire by setting the

discharge temperature control or

thermostat to its maximum setting. If the

ambient temperature is warm, the unit

may not stay at high fire.

2. Measure the burner manifold pressure at

the manifold pressure test port (see

Control Center Layout on page 3) using a

“U” tube manometer. The pressure on

high fire should be 3.5 in. wg for natural

gas and 10 in. wg for LP gas. To change

the pressure, adjust the regulator

adjustment screw on the combination gas

valve.

3. Set the unit to low fire by removing the

wire from the high fire terminal on the

combination gas valve.

4. The manifold pressure on low fire for natural gas

should be 0.88 in. wg and 2.5 in. wg for LP gas. To

change the pressure, use the low fire adjustment

screw on the combination gas valve.

Staged Burner Adjustments

Furnace Controls

For Energy Recovery Units without Temperature Control Package

The furnace stage controls are located in the furnace control center. One control is

provided for each stage of heating. The discharge temperature setting is located on

the control furthest to the left. The offset and differential settings for each stage are

preset at the factory; however, field-adjustments may be made to get the best control

for your application. See the literature provided with the controls for further

information.

For Energy Recovery Units with Temperature Control Package

If two-stage control is ordered with a Temperature Control Package, the controller in

the unit’s main control center will control the stages of heating. The temperature set

point may be adjusted on the controller (See Temperature Controller IOM).

Staged Temperature Controls

Performance Data

Ratings shown are for elevations up to 2000 ft. For higher elevations, the input should be reduced by 4% per 1000 ft. of

elevation above sea level. In Canada, from 2000 to 4500 ft in elevation, the unit must be derated to 90% of the input listed

above. The unit shall also be used in accordance with standard CGA 2.17.

High Fire Adjustment

Low Fire Adjustment

Solenoid

High Fire

Terminal

Air Temperature Rise Through Unit (°F)

Model

Input Output

20

25

30

35

40

45

50

55

60

65

70

75

80

85

90

95

100

Number

(MBH) (MBH)

CFM

PVF 100

100

80

3704

2963 2469 2116 1852

1646

1481 1347 1235

1140 1058

988

926

871

823

780

741

PVF 150

150

120

5556

4444

3704 3175 2778

2469

2222 2020 1852

1709 1587 1481 1389 1307 1235

1170 1111

PVF 200

200

160

7407

5926

4938 4233 3704

3292

2963 2694 2469

2279 2116 1975

1852 1743 1646

1559 1481

PVF 250

250

200

9259

7407

6173 5291 4630

4115

3704 3367 3086

2849 2646

2469 2315 2179 2058

1949 1852

PVF 300

300

240

11111 8889

7407 6349 5556

4938

4444 4040 3704 3419 3175 2963 2778 2614 2469

2339 2222

PVF 350

350

280

12963 10370 8642 7407 6481

5761

5185 4714 4321 3989 3704

3457 3241 3050 2881

2729 2593

PVF 400

400

320

14815 11852 9877 8466 7407

6584

5926

5387 4938 4558 4233

3951 3704 3486 3292 3119 2963

Figure 3: Staged Controls

Figure 4: Combination Gas Valve

5