Goodman Mfg VC8 User Manual

Page 10

10

E

XTERIOR

MASONRY

C

HIMNEYS

- C

ATEGORY

I F

URNACES

O

NLY

heating/cooling costs but have created a problem supplying

combustion and ventilation air for gas fired and other fuel burn-

ing appliances. Appliances that pull air out of the house (clothes

dryers, exhaust fans, fireplaces, etc.) increase the problem by

starving appliances for air.

House depressurization can cause back drafting or improper

combustion of gas-fired appliances, thereby exposing building

occupants to gas combustion products that could include car-

bon monoxide.

If this furnace is to be installed in the same space with other

gas appliances, such as a water heater, ensure there is an

adequate supply of combustion and ventilation air for the other

appliances. Refer to the latest edition of the National Fuel Gas

Code NFPA 54/ANSI Z223.1 or CAN/CSA B149 Installation

Codes or applicable provisions of the local building codes for

determining the combustion air requirements for the appliances.

This furnace must use indoor air for combustion. It cannot be

installed as a direct vent (i.e., sealed combustion) furnace.

Most homes will require outside air be supplied to the furnace

area by means of ventilation grilles or ducts connecting directly

to the outdoors or spaces open to the outdoors such as attics

or crawl spaces.

C

ATEGORY

I V

ENTING

(V

ERTICAL

V

ENTING

)

T

O

PREVENT

POSSIBLE

PERSONAL

INJURY

OR

DEATH

DUE

TO

ASPHYXIATION

,

THIS

FURNACE

MUST

BE

C

ATEGORY

I

VENTED

. D

O

NOT

VENT

USING

C

ATEGORY

III

VENTING

.

WARNING

Category I Venting is venting at a non-positive pressure. A

furnace vented as Category I is considered a fan-assisted ap-

pliance and the vent system does not have to be “gas tight.”

NOTE: Single stage gas furnaces with induced draft blowers

draw products of combustion through a heat exchanger allow-

ing, in some instances, common venting with natural draft ap-

pliances (i.e. water heaters). All installations must be vented in

accordance with National Fuel Gas Code NFPA 54/ANSI Z223.1

- latest edition. In Canada, the furnaces must be vented in ac-

cordance with the National Standard of Canada, CAN/CSA

B149.1 and CAN/CSA B149.2 - latest editions and amendments.

NOTE: The vertical height of the Category I venting system

must be at least as great as the horizontal length of the venting

system.

T

O

PREVENT

POSSIBLE

PERSONAL

INJURY

OR

DEATH

DUE

TO

ASPHYXIATION

,

COMMON

VENTING

WITH

OTHER

MANUFACTURER

’

S

INDUCED

DRAFT

APPLIANCES

IS

NOT

ALLOWED

.

WARNING

The minimum vent diameter for the Category I venting system

is as shown:

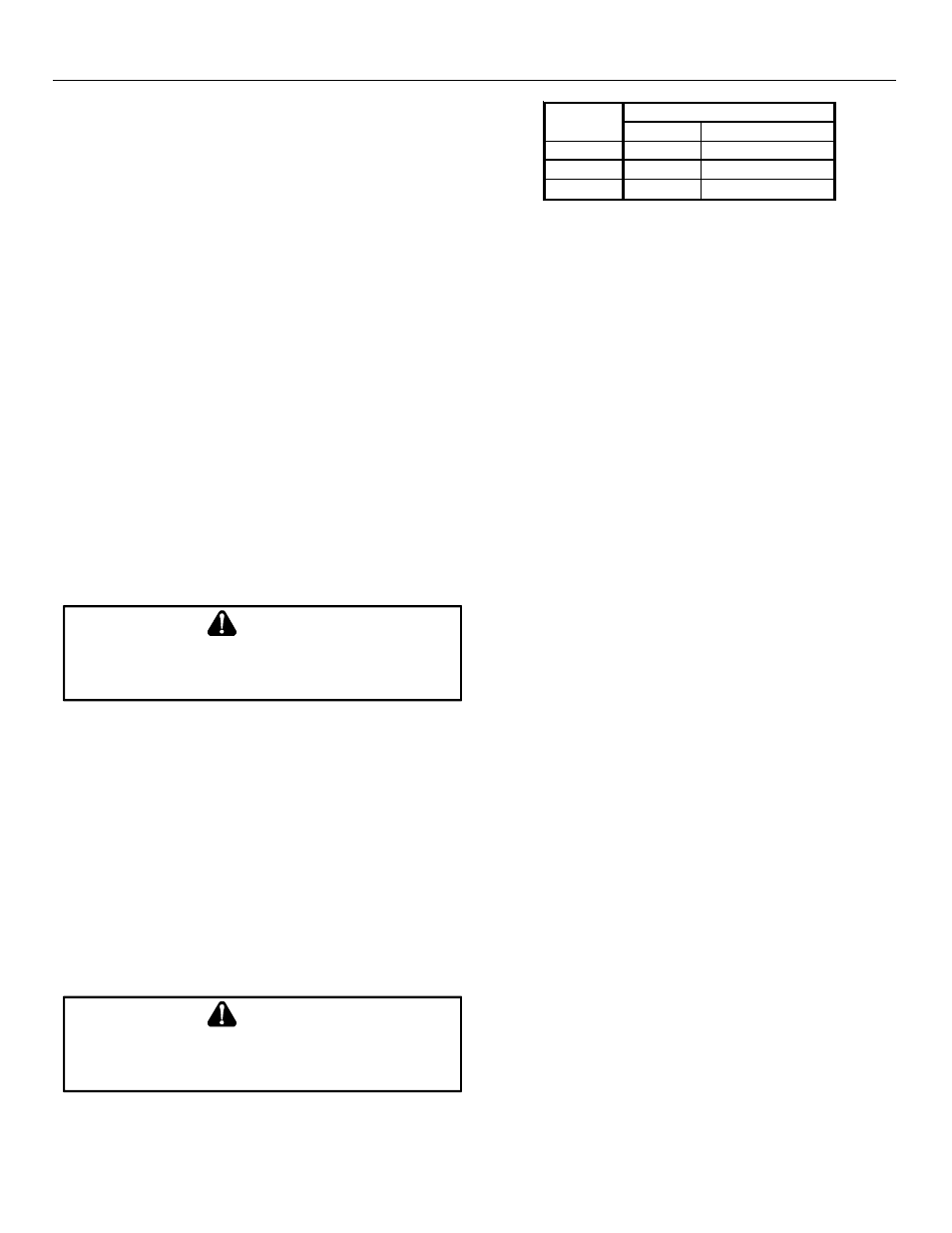

UPFLOW COUNTERFLOW

70

4 inch

4 inch

90

4 inch

4 inch

115

5 inch

4 inch

MINIMUM VENT

MODEL

Under some conditions, larger vents than those shown above

may be required or allowed. When an existing furnace is re-

moved from a venting system serving other appliances, the

venting system may be too large to properly vent the remaining

attached appliances.

Upflow or Horizontal units are shipped with the induced draft

blower discharging from the top of the furnace. (“Top” is as

viewed for an upflow installation.) The induced draft blower can

be rotated 90 degrees for Category I venting. For horizontal

installations, a four inch single wall pipe can be used to extend

the induced draft blower outlet 1/2” beyond the furnace cabinet.

THIS PRODUCT IS NOT DESIGNED FOR COUNTERCLOCK-

WISE INDUCED DRAFT BLOWER ROTATION.

Vent the furnace in accordance with the National Fuel Gas

Code NFPA 54/ANSI Z223.1 - latest edition. In Canada, vent

the furnace in accordance with the National Standard of Canada,

CAN/CSA B149.1 and CAN/CSA B149.2 - latest editions and

amendments.

Venting

THIS FURNACE IS NOT DESIGN CERTIFIED TO BE HORI-

ZONTALLY VENTED.

To rotate the induced draft blower clockwise, you will need to

purchase one (0270F01119) chimney transition bottom kit.

1. Disconnect electrical power from the furnace.

2. Disconnect the induced draft blower power leads, flue

pipe, and pressure switch tubing.

3. Remove the round cutout from the right side of the wrapper.

4. Remove and save the four screws that fasten the induced

draft blower to the flue collector box.

5. Remove and save the three screws that hold the chimney

assembly to the induced draft blower.

6. Remove and save the four screws that fasten the chimney

top to the chimney bottom.

7. Remove the chimney transition bottom from the transition

bottom kit.

8. Install the chimney top with the four screws retained

from step 6 onto the new chimney transition bottom from

the transition bottom kit.

9. Install chimney assembly with the three screws retained

from step 5 onto the induced draft blower.

10. Reinstall the induced draft blower rotating it 90 degrees

clockwise from the original upflow configuration using

the four screws retained in step 3. Ensure the gasket

located between the induced draft blower and the collector

box is rotated accordingly.