Generac Power Systems Quietpact 75 User Manual

Page 57

S

Se

ec

cttiio

on

n 7

7

D

DIIA

AG

GN

NO

OS

ST

TIIC

C T

TE

ES

ST

TS

S

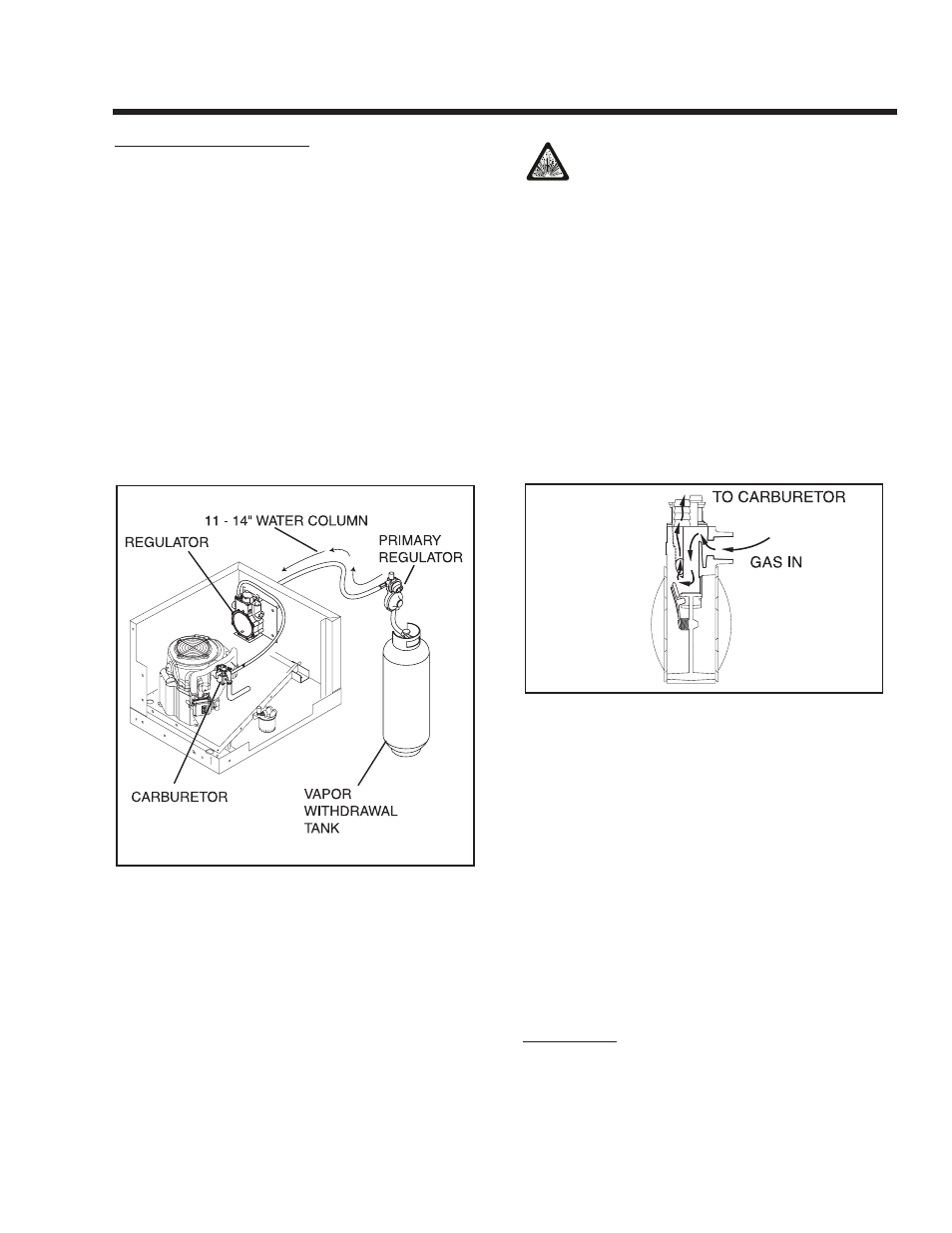

DISCUSSION (LPG MODELS):

LP gas is stored in pressure tanks as a liquid. The

gas systems used with these generators were

designed only for vapor withdrawal type systems.

Vapor withdrawal systems use the gas vapors that

form above the liquid fuel in the tank. Do NOT attempt

to use the generator with any liquid withdrawal type

system.

Gas pressure delivered to the solenoid valve must be

properly regulated by means of a primary gas regula-

tor. Mount the primary regulator at the gas tank outlet

or in the supply line from the gas tank. The following

rules apply:

• For best results, the primary regulator supplies

gaseous fuel to the secondary regulator at 11 inch-

es water column. Do NOT exceed 14 inches water

column.

• The installer must be sure the primary regulator is

rated at sufficient gas flow to operate the generator

plus all other gas appliances in the circuit.

Figure 7-27 – Typical Propane Gas Fuel System

NOTE: Recommended MINIMUM gas flow rate for

all air-cooled QUIETPACT series generators is 67

cubic feet per hour.

If an existing primary gas regulator does not have

a sufficient flow capacity for the generator and

other gas appliances in the circuit, (a) install a pri-

mary regulator with adequate flow rate, or (b)

install a separate regulator only and rated at least

67 cubic feet per hour. The inlet side of any prima-

ry regulator that supplies the generator must con-

nect directly to a gas pressure tank. Do NOT tee

the generator line into a gas circuit feeding other

areas.

C

CA

AU

UT

TIIO

ON

N!!:: U

Us

se

e o

on

nlly

y a

ap

pp

prro

ov

ve

ed

d c

co

om

mp

po

on

ne

en

ntts

s iin

n

tth

he

e ffu

ue

ell s

su

up

pp

plly

y s

sy

ys

stte

em

m.. A

Allll c

co

om

mp

po

on

ne

en

ntts

s m

mu

us

stt b

be

e

p

prro

op

pe

errlly

y iin

ns

stta

alllle

ed

d iin

n a

ac

cc

co

orrd

da

an

nc

ce

e w

wiitth

h a

ap

pp

plliic

ca

ab

blle

e

c

co

od

de

es

s.. IIm

mp

prro

op

pe

err iin

ns

stta

alllla

attiio

on

n o

orr u

us

se

e o

off u

un

na

au

utth

ho

o--

rriiz

ze

ed

d c

co

om

mp

po

on

ne

en

ntts

s m

ma

ay

y rre

es

su

ulltt iin

n ffiirre

e o

orr a

an

n e

ex

xp

pllo

o--

s

siio

on

n.. F

Fo

ollllo

ow

w a

ap

pp

prro

ov

ve

ed

d m

me

etth

ho

od

ds

s tto

o tte

es

stt tth

he

e s

sy

ys

s--

tte

em

m ffo

orr lle

ea

ak

ks

s.. N

No

o lle

ea

ak

ka

ag

ge

e iis

s p

pe

errm

miitttte

ed

d.. D

Do

o n

no

ott

a

allllo

ow

w ffu

ue

ell v

va

ap

po

orrs

s tto

o e

en

ntte

err tth

he

e v

ve

eh

hiic

clle

e iin

ntte

erriio

orr..

LP gas vapors should be supplied to the secondary

regulator inlet at about 11 inches water column (posi-

tive pressure). The engine pistons draw air in during

the intake stroke (Figure 7-28). This air passes

through a carburetor venturi, which creates a low

pressure that is proportional to the quantity of air

being pumped. The low pressure from the carburetor

venturi acts on the regulator diaphragm to pull the

diaphragm toward the source of low pressure. A lever

attached to the diaphragm opens a valve to permit

gas glow through the carburetor.

Figure 7-28 – LP Gas Carburetion Diagram

The greater the airflow through the carburetor venturi,

the lower the pressure at the venturi throat. The

lower the pressure at the venturi throat, the greater

the diaphragm movement, and the greater the move-

ment of the regulator valve. The more the regulator

valve opens, the greater the gas flow that is propor-

tional to airflow through the generator.

The following facts about the secondary regulator

must be emphasized:

• The regulator must be sensitive to venturi throat

pressure changes throughout the operating range.

• The regulator must be properly adjusted so it will

stop the flow of gas when the engine is not running

(no air flow through the carburetor).

• The slightest airflow (and vacuum in the venturi

throat) should move the regulator valve off its seat

and permit gas to flow.

PROCEDURE:

A water manometer or a gauge that is calibrated in

“ounces per square inch” may be used to measure

the fuel pressure. Fuel pressure at the inlet side of the

LPG Shut Off Valve should be between 11-14 inches

Page 55