Operation, Using the rip fence, Cutting – Global Machinery Company RBS10 User Manual

Page 10: Maintenance, General inspection, Repairs

Operation

Switching on and off

1. Connect the plug to the power supply.

2. Depress the ON button.

3. To switch off, depress the OFF button.

NOTE.

1. The saw must be connected to an earthed outlet and

should be operated on a residual current device (RCD)

of 30 mA capacity.

2. Extension leads must have a minimum lead cross

section of 3 x 0.75 mm (240V).

3. The saw is automatically turned off in the event of a

power failure. You will need to press the ON button

again to restart the saw (only on some models).

Using the rip fence

The rip fence allows you to make parallel cuts in a sheet

of wood, all at the same width.

WARNING.

Always ensure that the saw is switched off

and unplugged from the power supply before making any

adjustments.

1. Adjust the rip fence to the required width and secure it

in position with the locking handle.

2. Ensure that the fence rests against the wood along its

entire length to give a consistent parallel cut.

Cutting

NOTES.

1. Use only enough pressure to keep the saw cutting.

Do not force the cutting.

Allow the blade and the saw

to do the work.

2. When cutting at an angle

ensure that the rip fence is

located on the right hand side

of the blade.

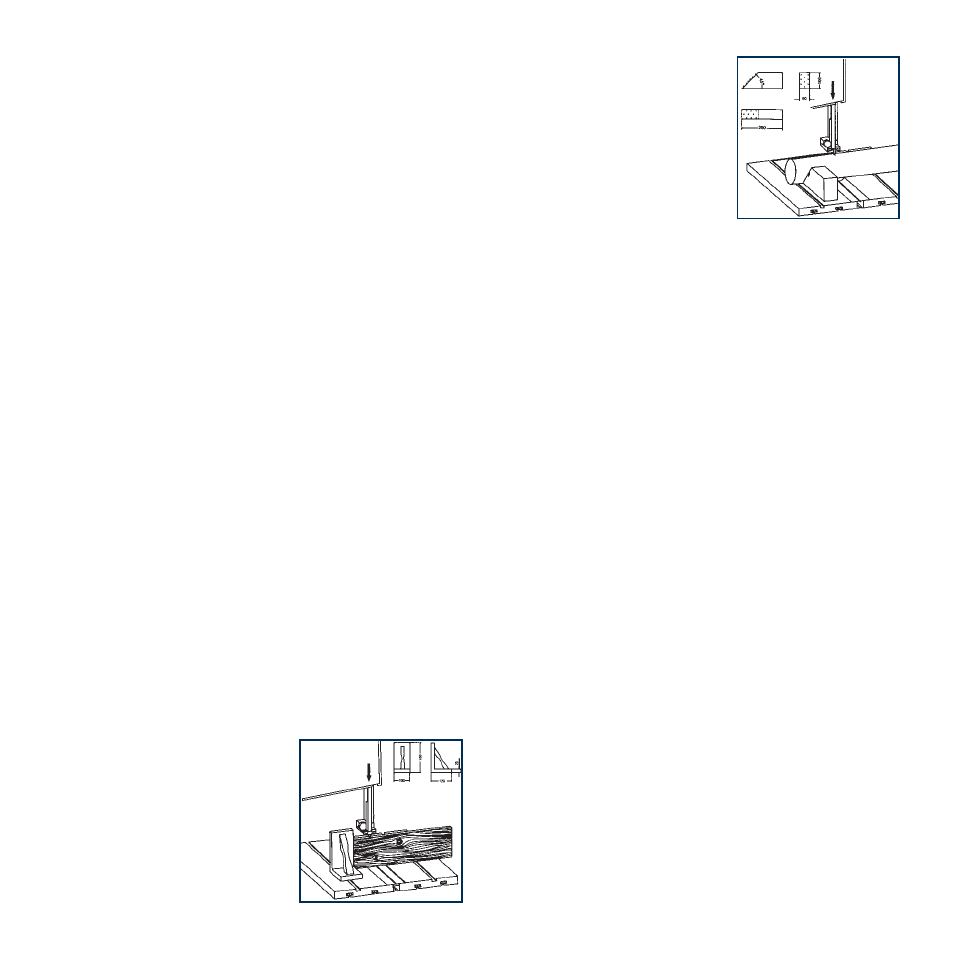

3. When cutting rod, use a jig

or fixture to prevent the

workpiece from turning.

4. When cutting boards vertically,

use a suitable push block to

feed the workpiece into the

saw.

Maintenance

Cleaning

Note.

Always wear eye protection when cleaning the tool.

1. Keep the tool’s air vents unclogged and clean at all

times.

2. Remove dust and dirt regularly. Cleaning is best done

with compressed air or a rag.

3. Re-lubricate all moving parts at regular intervals.

4. Never use caustic agents to clean plastic parts.

CAUTION.

Do not use cleaning agents to clean the plastic

parts of the saw. A mild detergent on a damp cloth is

recommended. Water must never come into contact with

the saw.

General inspection

1. Regularly check that all the fixing screws are tight.

They may vibrate loose over time.

Repairs

Call GMC on 1300 880 001

We can advise you as to the best method to repair

your tool.

Please do not return the tool to the store where you

purchased it without first contacting GMC.

10