Direct drive selections – Greenheck Fan QEP User Manual

Page 12

Direct drive construction offers many advantages for commercial or

industrial air handling applications.

- Reduced maintenance (no belts and shaft bearings to service)

- Compact housing design requires a smaller footprint

- Low vibration

- Suitable for clean air application (no belt or bearing residue in airstream)

Flow Control Options

%JSFDUESJWFNPEFMTSFRVJSFBWBSJBCMFGSFRVFODZESJWF 7'%PSBQBSUJBM

width wheel to assist in matching actual fan performance to the desired

QPJOUPGPQFSBUJPO"7'%BMMPXTUIFGBOQFSGPSNBODFUPCFBEKVTUFEUP

assist in system balancing and provides flexibility in adapting to future

TZTUFNDIBOHFT7'%TJODPOKVODUJPOXJUIB2&.PS2&1DBOBTTJTUJO

reducing energy consumption. Partial wheel widths can also be used to

attain a specific fan performance. Partial wheel widths are available in

JODSFNFOUTSBOHJOHGSPNo

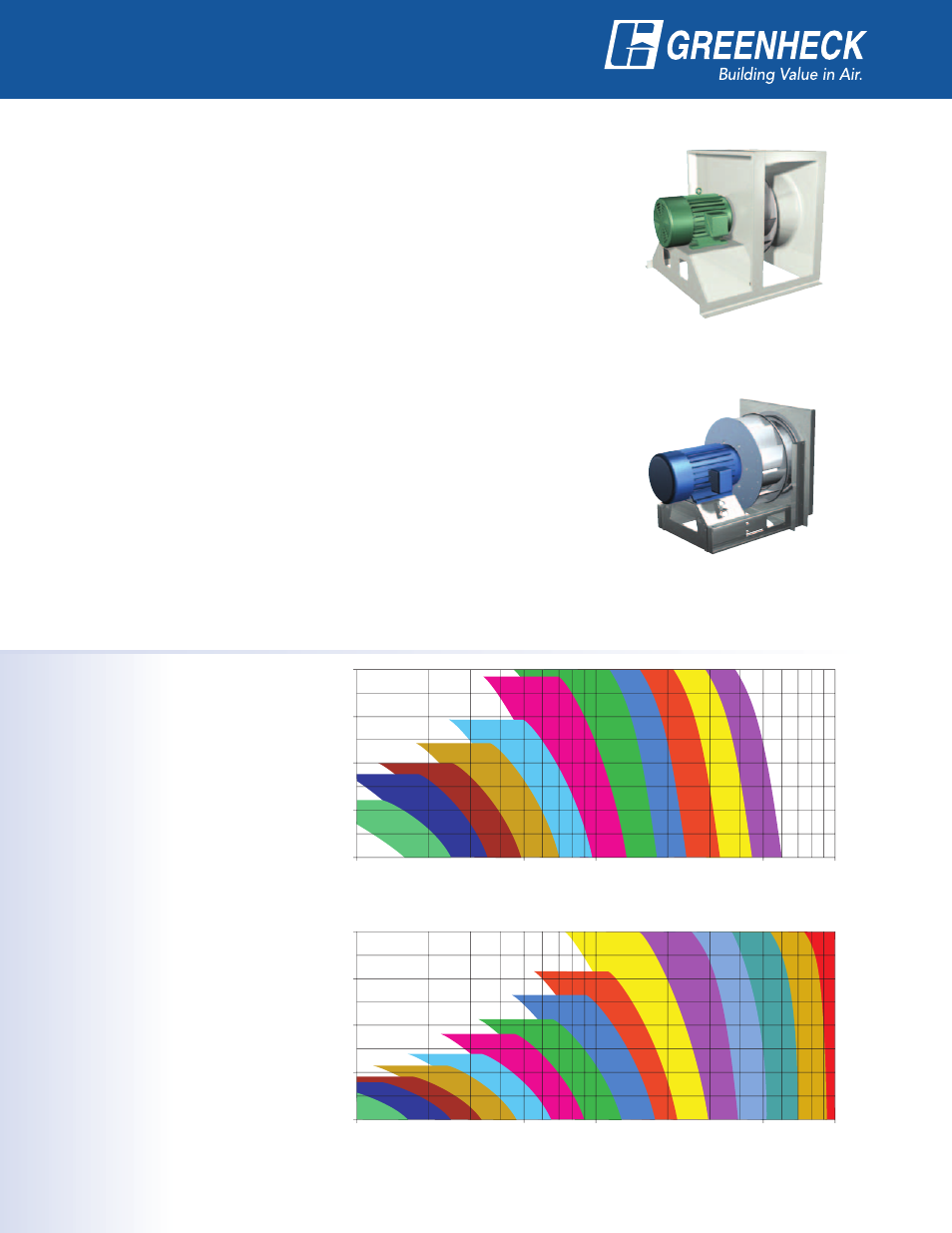

The charts on these pages allow for a quick estimation of the required fan

size and motor speed to achieve the desired point of operation. Colored

bands for a given size in each chart show the acceptable performance

range for the most commonly selected fan sizes at a given motor speed.

For detailed selection information, please consult our Computer Aided

Product Selection (CAPS) software.

Direct Drive

Selections

QEP Arrangement 4

Horizontal, Direct Drive

QEM Arrangement 4

Horizontal, Direct Drive

7PMVNF DGNY

4

3

2

1

0

1 5

10 50

100

15

16

18

20 22 24 27 30 33 36 40

4

3

2

1

0

1 5

10 50

100

15

16

18

20 22 24 27 30 33 36 40 44 49 54 60

Static

Pressure

(in. wg)

7PMVNF DGNY

Static

Pressure

(in. wg)

1425 RPM

(50 Hz)

Model QEM

4J[FT

Model QEP

4J[FT

950 RPM

(50 Hz)

Model QEM

4J[FT

Model QEP

4J[FT

Direct Drive models are not licensed to bear the AMCA Seal

12