Exhaust venting, Water supply – GSW 72090 User Manual

Page 11

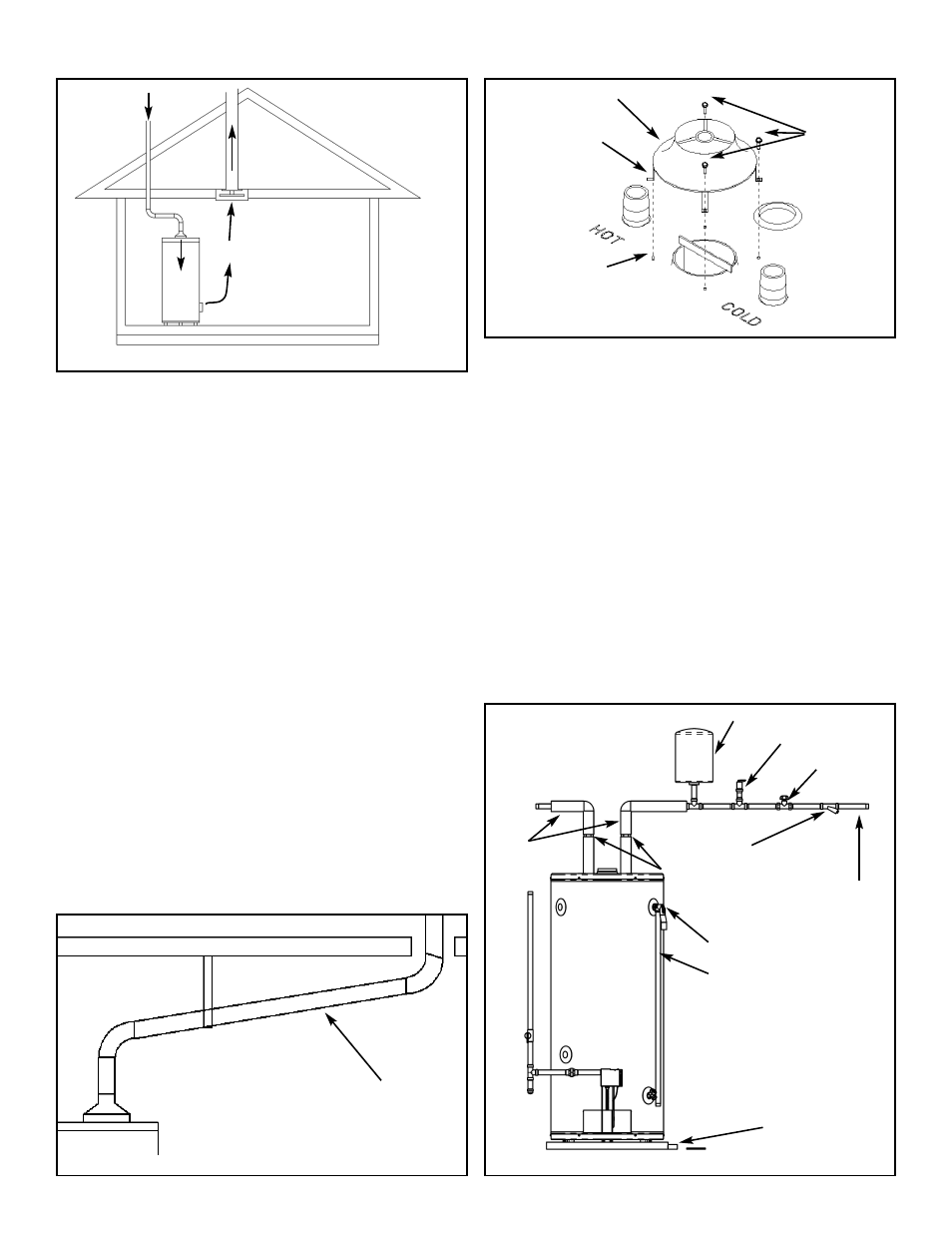

Exhaust Venting

Vent Pipe System

This water heater is a Category 1, non-direct vented appli-

ance.

The vent pipe must be installed in accordance with all local

and provincial or state codes or, in the absence of such

codes, with the latest edition of “Natural Gas and Propane

Installation Code” CAN/CSA-B149.1

in Canada,

“National Fuel Gas Code” ANSI Z223.1 (NFPA 54) in the

U.S.A. The vent pipe must not be obstructed so as to pre-

vent the removal of exhaust gases to the outside atmos-

phere.

Note: The horizontal section of the vent must slope up

21mm per metre (1/4 in. per foot), (see Figure 8).

U.L. recognized fuel gas and carbon monoxide (CO) detec-

tors are recommended in all applications and should be

installed using the manufacturer’s instructions and local

codes, rules or regulations.

Important: If you lack the necessary skills required to prop-

erly install this venting system, you should not proceed, but

enlist the help of a qualified service technician.

Drafthood Installation

Hook the tab leg of the drafthood into the slot in the heater’s

top. Align the remaining legs with the hole/dimples and

secure the drafthood to the top with three screws as shown

in Figure 9. Do not alter the drafthood in any way. If you are

replacing an existing water heater be sure to use the new

drafthood supplied with the water heater.

Water Supply

Piping Installation

Piping, fittings, and valves should be installed according to

the installation drawing (Figure 10). If the indoor installation

area is subject to freezing temperatures, the water piping

must be protected by insulation. Water supply pressure

should not exceed 550 kPa (80psi). If this occurs a pressure

reducing valve and/or an expansion tank may be required.

The pressure reducing valve should be placed on the sup-

ply to the entire house in order to maintain equal hot and

cold water pressures.

Important: Heat must not be applied to the water fittings on

the heater as they may contain nonmetallic parts. If solder

connections are used, solder the pipe to the adapter before

attaching the adapter to the hot and cold water fittings.

Install the water piping and fittings as shown in Figure 10.

Connect the cold water supply to the fitting (3/4” NPT)

marked “COLD” (or “C”). Connect the hot water supply to

the fitting (3/4” NPT) marked “HOT” (or “H”).

REVERSE

FLOW OF

GASES

EXHAUST

FAN

Figure 7 Air Moving Devices

SLOPE UP 21mm PER METRE

(1/4 in. PER ft) MIN.

Figure 8 Vent System

DRAFTHOOD

Figure 9 Drafthood Installation

TAB LEG

SLOT

SCREW

Figure 10 Example Of Water Piping Installation

IN A CLOSED SYSTEM USE EITHER:

1.THERMAL EXPANSION TANK

2.PRESSURE RELIEF VALVE

COLD WATER

INLET VALVE

UNION

PRESSURE REDUCING

VALVE WITH BYPASS

COLD WATER

INLET

T E M P E R A T U R E A N D

PRESSURE RELIEF VALVE

DISCHARGE LINE 300mm

(12 in.) MAX (CANADA) OR

150mm (6 in.) MAX (U.S.A.)

ABOVE DRAIN

M A S S A C H U S E T T S :

I N S TA L L A VA C U U M

RELIEF IN COLD WATER

L I N E P E R S E C T I O N

19MGL 142

DRAIN LINE 19mm

(3/4 in.) ID MIN

HOT WATER

OUTLET

PIPE

INSULATION

– 11 –