Alco controls division • emerson electric co – Grindmaster AMERICAN METAL WARE 87710 User Manual

Page 18

American Metal Ware 87710E Coffee Urn

Page 19

Disassembly

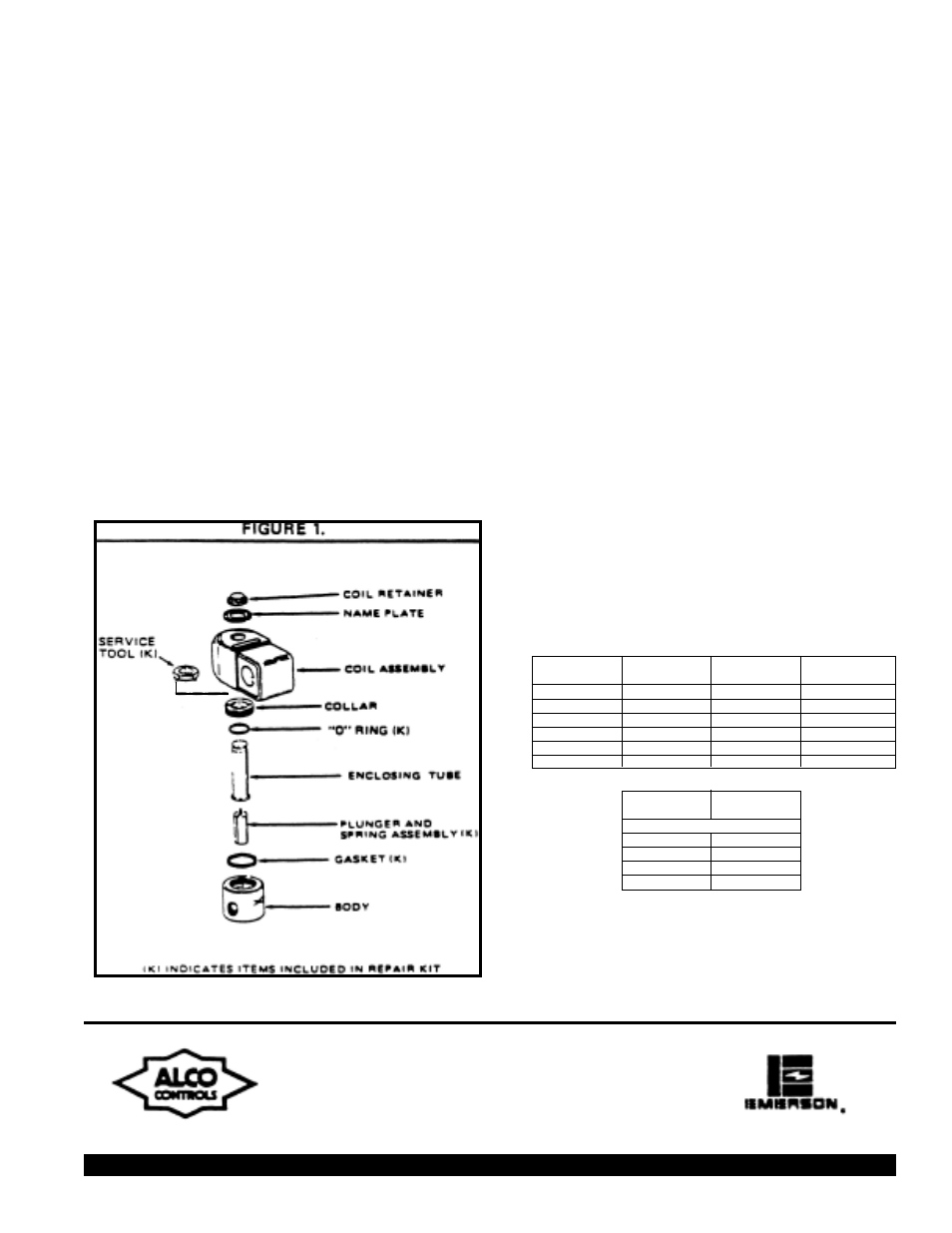

Disassemble in the same general order as indicated in exploded -

view illustrations except as noted in the following steps:

1.

2.

3.

Assembly

1.

2.

3.

Troubleshooting

1.

2.

De-pressurize valve and disconnect electrical power source.

To remove solenoid coil:

Insert small screwdriver into gap in voltage nameplate. Slide

screwdriver tip under coil retainer and snap off. If replacing

coil, use knife to separate adhesive-backed valve nameplate

from coil. Keep valve nameplate.

To remove collar, use service tool X11981-1 shown in Figure 1

Note:

Do NOT lose nameplate, as it is extremely important

if it becomes necessary to order a parts kit, coil or

duplicate valve.

Assemble in the reverse general order of disassembly.

Lubricate gasket and “O” ring sparingly with a compatible

lubricant such as a Silicon base lubricant.

All moving parts must move freely over the full length of its

intended travel.

Check system fuses, electrical wiring and system source

voltage as specified.

Is flow direction arrow on valve the same as system flow

direction?

Cleaning

As with all valves, it may become necessary to clean them

periodically to keep them in peak operating condition. Any

cleaning methods or fluids used should be compatible with

valve materials.

Inspection

1.

2.

Testing

1.

2.

3.

4.

5.

Repair Kits - The following Repair Kits are available.

Coils

1.

2.

3.

All moving parts and elastomers should be clean in

appearance without permanent set; springs should be

free of corrosion. If any appear damaged, replace them

with a parts kit which contains all moving parts

necessary to rebuild valve to an “as new” condition.

Inspect enclosing tube assembly for wear, exterior dents

or other conditions which would impair free movement of

the poppet and/or plunger assembly. Its interior should

be clean and free from any obstructions. Be especially

critical of its valve seat.

Apply correct voltage to valve solenoid and cycle

solenoid several times. A distinct click should be heard

each time the solenoid is energized.

Pressurize valve and check for leaks.

Note: Alco solenoid valves are equipped with a

continuous-duty solenoid coil, which when energized for

an extended period of time becomes hot to the touch.

This is a safe operating temperature. Any excessive

heating will be indicated by smoke and odor of burning

coil insulation.

Are all system relays operating?

Is system source pressure as specified?

Are all system components free from obstruction?

Junction box (AMG) is supplied as standard on all

valves.

The following coil housings are available:

a. Conduit Connection (AMC)

c. Open Frame (AMF)

b. GROMMET 18” Leads (AML) d. Spade Connection (AMS)

Use only Alco coils on Alco valves.

Alco Controls Division • Emerson Electric Co.

P.O. Box 12700 • St. Louis, Missouri 63141 • 314-569-4500

Customer Service • 314-569-4666

Valve

Series

202CB -B

202CB -F

202CB -N

202CB -P

202CB -T

202CB -V

Kit

Part No.

K-1063

K-1066

K-1067

K-1064

K-1068

K-1065

Valve

Series

204CD -B

204CD -F

204CD -N

204CD -P

204CD -T

204CD -V

Kit

Part No.

K-1072

K-1075

K-1073

K-1076

K-1077

K-1074

Valve

Series

204CD -B

204CD -V

204CD -T

204CD -P

Kit

Part No.

K-1162

K-1164

K-1167

K-1166

For 1/4” Orifice Only