Shimming upper wheel – Grizzly G0513X2 User Manual

Page 68

-66-

G0513 Series Bandsaws

—

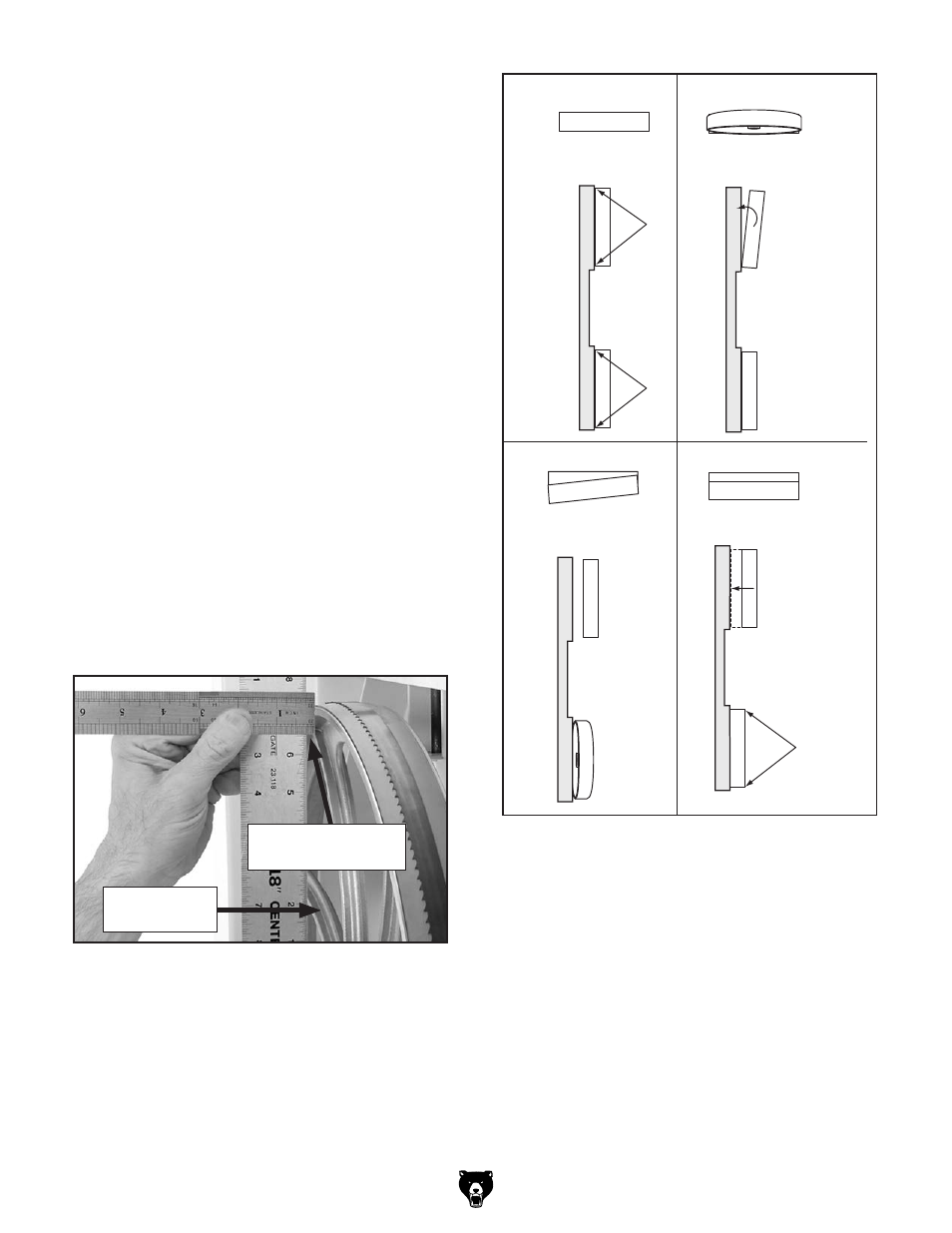

if the wheels are coplanar (Figure 99, A),

the straightedge will evenly touch the top

and bottom of both wheels.

—

if the wheels are not coplanar (Figure 99,

B), place the straightedge on the lower

wheel first (ensuring that it touches both

the top and bottom rim), then adjust the

upper wheel tracking knob to make the

upper wheel coplanar and parallel with the

lower wheel.

— if the straightedge does not touch both

wheels evenly, the upper wheel needs to

be shimmed (

Figure 99, D) or the lower

wheel needs to be adjusted (

Figure 99,

c).

Shimming Upper Wheel

1. disCoNNECt BaNdsaW FroM poWEr!

2. Make sure the top wheel is adjusted parallel

with the bottom wheel.

3. With a straightedge touching both points of

the wheel that does not need to be adjusted,

measure the distance away from the wheel

that is out of adjustment (see

Figure 98).

Coplanar

Parallel, Not

Coplanar

Not Coplanar

Gauge

Contacts Top

And Bottom of

Both Wheels

Gauge Only

Contacts Bottom

Wheel

Gauge Only

Contacts Bottom

Wheel. Top Wheel

Needs to Be Tilted.

Gauge Contacts

Wheels Unevenly

Coplanarity Gauge

Solution:

Shim Upper

Wheel Out

Not Parallel

Not Coplanar

Solution:

Adjust

Lower

Wheel

Hub

Solution:

Adjust

Tracking

Knob

A

D

C

B

Figure 99. Coplanar diagram.

Figure 98 determining distance needed to shim

upper wheel.

Wheel out of

adjustment

difference Between

Wheels

6. replace the wheel, the original washers, the

securing screw, and the blade.

7. tighten the blade, then check the wheels with

the coplanarity gauge. (Wheel coplanarity

changes as the blade is tightened, so it is

best to check the wheel alignment when the

blade is tensioned as it would be for normal

operations.)

4. remove the blade from the saw, then remove

the wheel that needs to be shimmed.

5. determine how many shim washers you need

to compensate for the distance measured in

Step 3 and place them on the wheel shaft.