Grindmaster 3312 User Manual

Page 10

CARE AND CLEANING

Drain and Rinse (cont.)

4. Remove the carburetor tube and pour water into the storage hopper. Allow the water to fill the freezing cylinder.

5. Turn the panel switch to “CLEAN” for 5 minutes.

6. Open the dispensing valve and drain the water from the freezer.

7. Turn the freezer “OFF”.

Disassembly and Cleaning

Note: For cleaning and sanitizing before initial start-up remove carb tubes, dispense plungers, handles and springs

from parts bag first.

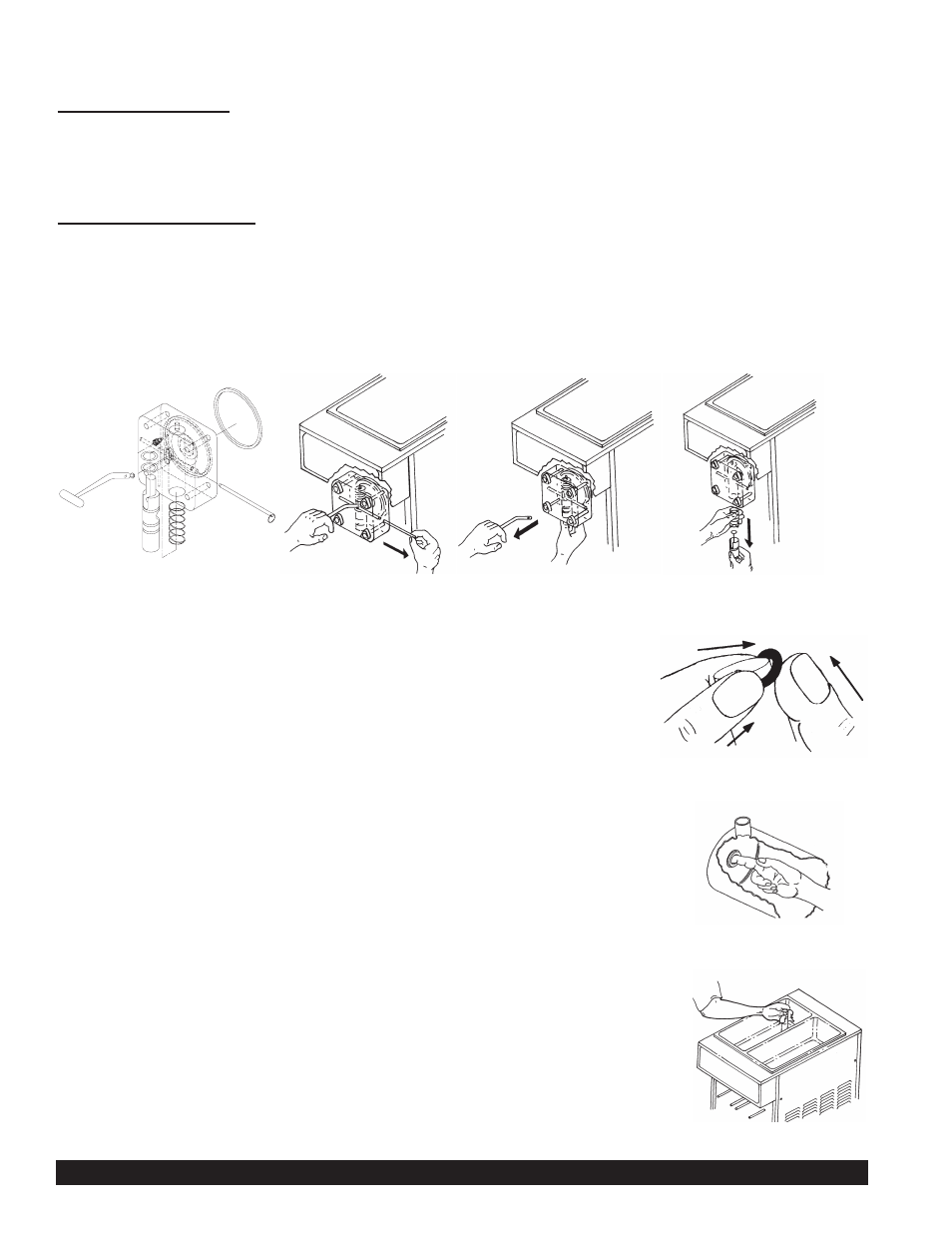

1. Disassemble the dispensing valve assembly (Figure M). Pull out valve handle retaining pin while supporting the

valve plunger from the bottom (Figure N). Push up on the valve plunger and remove the stainless handle

(Figure O). Slide the valve plunger and spring downward to remove (Figure P).

2. Remove knobs and carefully remove the front dispensing valve assembly, leaving the dasher assembly in the

cylinder. Remove the o-rings from the plunger assembly and back of the dispensing valve body. (See Figure Q)

NOTE: The best way to remove an o-ring is to first wipe off all of the lubricant using a

clean paper towel. Pinch the o-ring upward with a dry paper towel between your index

finger and thumb. When a loop is formed in the o-ring, roll it out of the groove with

your other thumb. Always remove the o-ring farthest from the end of the plunger first.

Carefully inspect the o-rings and replace if necessary.

(See Figure Q)

3. Remove the dasher assembly from inside the freezing cylinder taking care to avoid

damaging the rear seal assembly at the back of the freezing cylinder. Disassemble

the dasher assembly by removing the stator rod and front and rear stator rod

bearings.

4. Remove stationary half of the shaft seal assembly from the back end of the

freezer cylinder. This is accomplished by reaching into the cylinder and pulling seal

out with your index finger. (See Figure R)

5. Slide the rotary half of the seal off the dasher shaft. Inspect both seal components

carefully for nicks or cracks. Replace seal if defective.

NOTE: To prevent leakage the surfaces of the rotary seal and the stationary seal must be

smooth with no chips or cracks.

NOTE: All units are shipped with a standard ceramic seal (Part # W0340201) unless

otherwise specified. Certain products contain coconut oil which requires a different sealing

material. For these products use the coconut oil seal (Part # W0340210). The stationary

half of the standard seal has a white polished surface. The stationary half of the coconut oil

seal has a glossy black surface.

6. Remove carb tube from bottom of hopper and remove o-rings. (See Figure S).

7. Repeat disassembly procedures on other side.

Figure N Remove Pin

Figure M Disassemble

Dispensing Valve

Figure O Remove Handle

Figure P Remove

Plunger and Spring

Figure Q Ring Removal

Page 8

Model 3312

Figure R Remove the

stationary half of seal

Figure S Carb Tube