6 fuel requirements and recommendations, 7 fuel consumption, 8 reconfiguring the fuel system – Generac 04389-0 User Manual

Page 9

Generac

®

Power Systems, Inc.

7

1.6

FUEL REQUIREMENTS

AND RECOMMENDATIONS

With LP gas, use only the vapor withdrawal

system. This type of system uses the vapors formed

above the liquid fuel in the storage tank.

The engine has been fitted with a fuel carburetion

system that meets the specifications of the 1997

California Air Resources Board for tamper-proof dual

fuel systems. The unit will run on natural gas or LP

gas, but it has been factory set to run on natural gas.

Should the primary fuel need to be changed to LP

gas, the fuel system needs to be reconfigured. See

Section 1.8 (Page 7) for instructions on reconfigura-

tion of the fuel system.

Recommended fuels should have a Btu content of at

least 1,000 Btus per cubic foot for natural gas; or at

least 2,520 Btus per cubic foot for LP gas. Ask your

fuel supplier for the Btu content of your fuel.

Fuel pressure for both natural gas and liquid

propane set ups should be 11 inches to 14 inches

of water column (0.6 psi)

at all load ranges.

NOTE:

A seperate gas line and regulator may be needed

to assure proper gas pressure (11-14”) to the gen-

erator. Low gas pressure can cause hard starting

and could affect engine durability.

1.7

FUEL CONSUMPTION

*Natural gas is in cubic feet per hour.

**LP is in gallons per hour/cubic feet per hour.

Gaseous fuels such as natural gas and liquid

propane (LP) gas are highly explosive. Even the

slightest spark can ignite such fuels and cause

an explosion. No leakage of fuel is permitted.

Natural gas, which is lighter than air, tends to

collect in high areas. LP gas is heavier than air

and tends to settle in low areas.

1.8

RECONFIGURING THE

FUEL SYSTEM

1.8.1 7 KW

To reconfigure the fuel system from NG to LP,

follow these steps:

1. Turn the main gas supply off.

2. Remove the carburetor fuel hose(s) from the outlet

port(s) of the demand regulator (Figure 1.4).

3. Disconnect wire #0 and wire #14 from the gas

solenoid located on the top of the demand regu-

lator.

4. Remove the demand regulator by rotating coun-

terclockwise.

5. Remove the brass hose fitting(s) from the outlet

port of the demand regulator.

6. Remove the brass metering jet(s) (loosen coun-

terclockwise) from the housing port of the

demand regulator located on the side of the regu-

lator.

7. Install new LP metering jet(s) (tighten clockwise)

in the outlet port of the demand regulator.

8. Refit the brass hose fittings to the outlet port of

the demand regulator.

9. Reverse procedure steps 1-4 to reinstall demand

regulator.

10. Reverse the procedure to convert back to natural

gas.

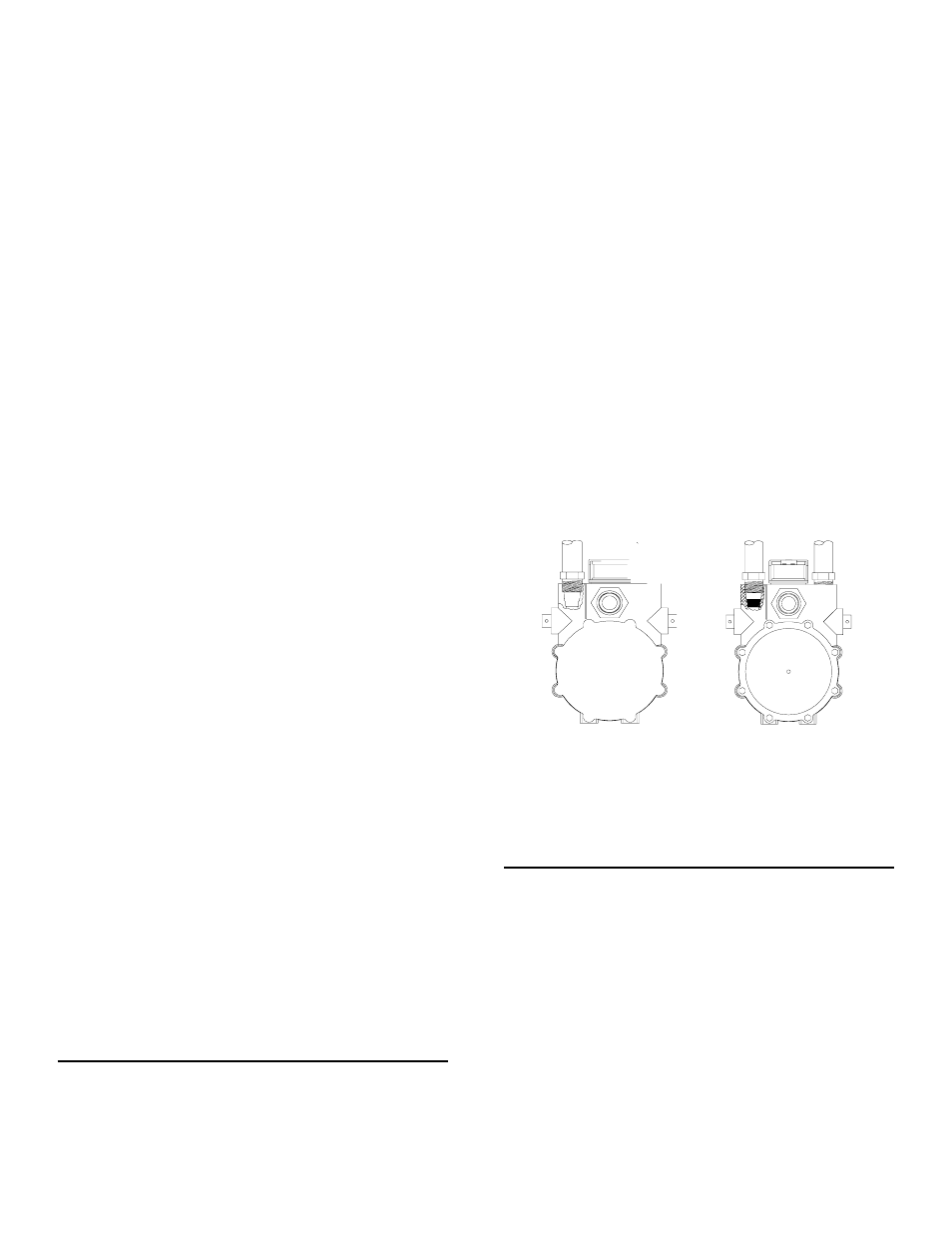

Figure 1.4 – Demand Regulator

NOTE:

The natural gas adjustment screw is preset during

installation and should not need any further

adjustment.

1.8.2 V-TWIN

To reconfigure the fuel system from NG to LP,

follow these steps:

NOTE:

The primary regulator for the propane supply is

NOT INCLUDED with the generator. You must sup-

ply a fuel pressure of 11 to 14 inches of water col-

umn (0.6 psi) to the fuel inlet of the generator.

1. Locate the fuel demand regulator underneath the

control panel.

2. Identify both fuel adjustment screws.

NOTE:

One adjustment screw can be accessed from the

front of the unit and the second can be accessed

from the back of the unit.

◆