Blade tensioning, Notice, Adjusting support bearings – Grizzly G0457 User Manual

Page 26

-24-

g0457 14" industrial Bandsaw (Mfg. Since 5/11)

Blade Tensioning

A properly tensioned blade is essential for mak-

ing accurate cuts and is a prerequisite for making

many bandsaw adjustments. the blade tension

scale shows the approximate tension, but the

steps below will allow you to get the optimum ten-

sion for the installed blade.

To tension the bandsaw blade:

1. Make sure you have completed the Test Run

procedure on

page 21 and that the blade is

tracking properly.

2. raise the upper blade guide assembly as

high as it will go, and adjust the upper and

lower guide blocks as far away from the blade

as possible.

Note: This procedure will NOT work if the

guide blocks have any contact with the

blade.

3. Adjust blade tension until the mark on the

blade tension scale matches the size of the

installed blade.

Note: This scale can only be considered a

general guide. Complete the following steps

to accurately set blade tension.

4. turn the bandsaw ON.

5. Slowly release the tension one quarter of a

turn at a time. When you see the bandsaw

blade start to flutter, stop decreasing the ten-

sion.

6. now, slowly increase the tension until the

blade stops fluttering, then tighten the tension

another quarter turn.

7. look at what the tension gauge reads and

use that as a guide for tensioning that blade

in the future.

Note: Always de-tension the blade after use

to increase blade life and reduce strain on the

bandsaw components.

NOTICE

After blade tension and tracking are set cor-

rectly, you MUST properly adjust the upper

and lower support bearings and guide-block

assemblies into position before cutting.

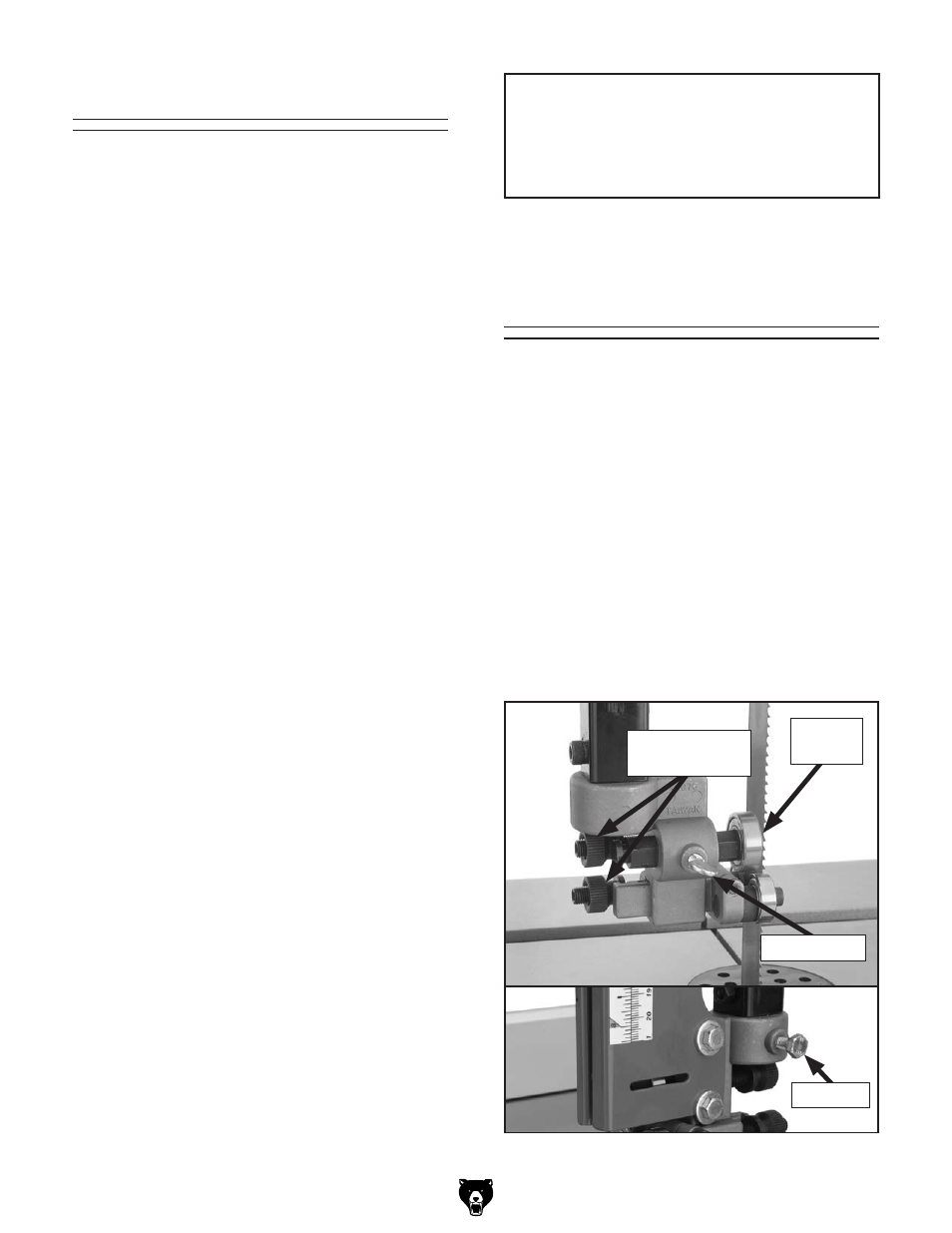

Adjusting Support

Bearings

the support bearings are positioned behind

the blade for support during cutting operations.

proper adjustment of the support bearings is an

important part of making accurate cuts and also

keeps the blade teeth from coming in contact with

the guide bearings while cutting.

To adjust the support bearings:

1. Make sure that the blade is tracking properly

and that it is correctly tensioned.

2. diSConneCt BAndSAW FroM poWer!

3. Familiarize yourself with the support bearing

controls shown in

figure 29.

figure 29. Support bearing controls.

Support

Bearing

thumbscrew

Upper Knurled

Knob

lock Bolt