6 fuel requirements and recommendations, 7 fuel consumption, 8 reconfiguring the fuel system – Guardian Technologies 04758-2 User Manual

Page 9: Danger

1.6

FUEL REQUIREMENTS

AND RECOMMENDATIONS

With LP gas, use only the vapor withdrawal sys-

tem. This type of system uses the vapors formed

above the liquid fuel in the storage tank.

The engine has been fitted with a fuel carburetion

system that meets the specifications of the 1997

California Air Resources Board for tamper-proof

dual fuel systems. The unit will run on natural gas or

LP gas, but it has been factory set to run on natural

gas. Should the primary fuel need to be changed to

LP gas, the fuel system needs to be reconfigured. See

Section 1.9 for instructions on reconfiguration of the

fuel system.

Recommended fuels should have a Btu content of at

least 1,000 Btus per cubic foot for natural gas; or at

least 2,520 Btus per cubic foot for LP gas. Ask the

fuel supplier for the Btu content of the fuel.

Required fuel pressure for natural gas is 5 inches to

7 inches water colum (0.18 to 0.25 psi); and for

liquid propane, 11 inches to 14 inches of water

column (0.4 to 0.5 psi).

NOTE:

Any piping used to connect the generator to the

fuel supply should be of adequate size to ensure

the fuel pressure NEVER drops below 4 inches

water colum for natural gas or 10 inches water

column for liquid propane for all load ranges.

1.7 FUEL

CONSUMPTION

*Natural gas is in cubic feet per hour.

**LP is in gallons per hour/cubic feet per hour.

DANGER

Gaseous fuels such as natural gas and liquid

propane (LP) gas are highly explosive. Even the

slightest spark can ignite such fuels and cause

an explosion. No leakage of fuel is permitted.

Natural gas, which is lighter than air, tends to

collect in high areas. LP gas is heavier than air

and tends to settle in low areas.

1.8

RECONFIGURING THE

FUEL SYSTEM

1.8.1 7 KW, 410CC

To reconfigure the fuel system from NG to LP, follow

these steps (Figure 1.3):

NOTE:

The primary regulator for the propane supply is

NOT INCLUDED with the generator. A fuel pres-

sure of 11 to 14 inches of water column (0.4 to

0.5 psi) to the fuel inlet of the generator MUST

BE SUPPLIED.

1. Turn off the main gas supply (if connected).

2. Open the roof and remove the door.

3. Remove the battery (if installed).

4. Disconnect wire #0 and wire #14 from the gas

solenoid on top of the demand regulator.

5. Remove the carburetor fuel hose from the outlet

port of the demand regulator.

6. Remove the demand regulator by removing the

fastener that retains the regulator mounting

bracket.

7. Remove the square headed steel pipe plug from

outlet port #1 and the brass hose barb fitting

from outlet port #2.

8. Refit the brass hose barb fitting to outlet port #1

and the square headed steel pipe plug to outlet

port #2.

9. Reverse procedure steps 1-5 to reinstall demand

regulator.

10. Take the plastic plug supplied in the poly-bag

with the generator and press it into the 3/4” hole

on the bottom of the air cleaner base (Figure

4.6).

11. Reverse the procedure to convert back to natural

gas.

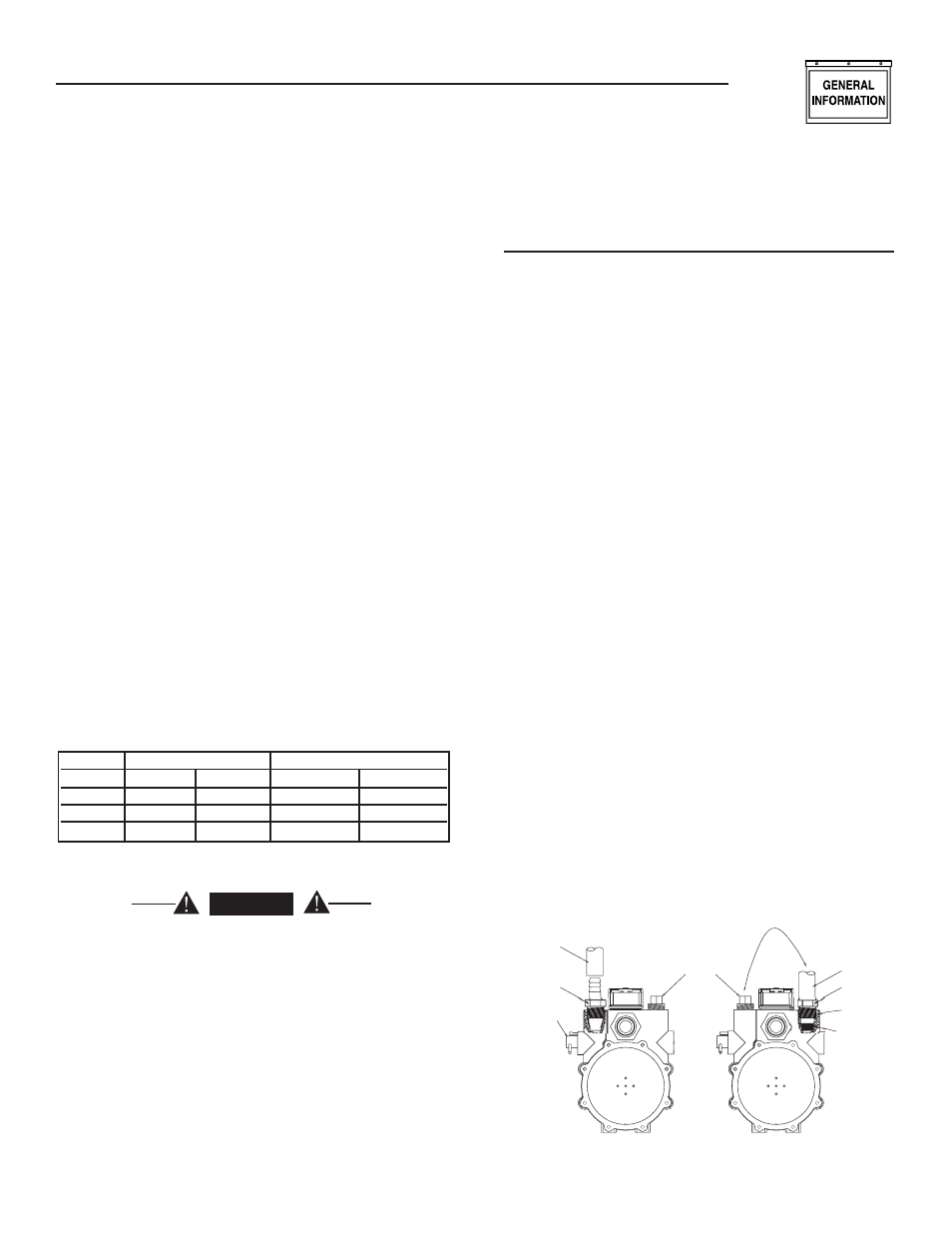

Figure 1.3 – Demand Regulator

NG FUEL SYSTEM

LP FUEL SYSTEM

FUEL HOSE

BRASS HOSE

FITTING

BRASS HOSE

FITTING

FUEL JET

OUTLET

PORT

FUEL HOSE

ADJUSTMENT

SCREW

HOSE & PLUG

SWITCHED SIDES

PIPE

PLUG

Section 1 — General Information

Air-cooled 7 kW, 12 kW and 15 kW Generators

Model #

Nat. Gas (*)

LP Vapor (**)

1/2

Load Full Load

1/2 Load

Full Load

04758

66

119

0.82/30

1.47/54

04759

152

215

1.53/56

2.08/76

04760

156

220

1.58/58

2.40/88

7