F-series, 22 statements of conformity – FORD SUPER DUTY F-SERIES 6C34-19A268-BA User Manual

Page 24

F-SERIES

(March, 2005)

22

STATEMENTS OF CONFORMITY

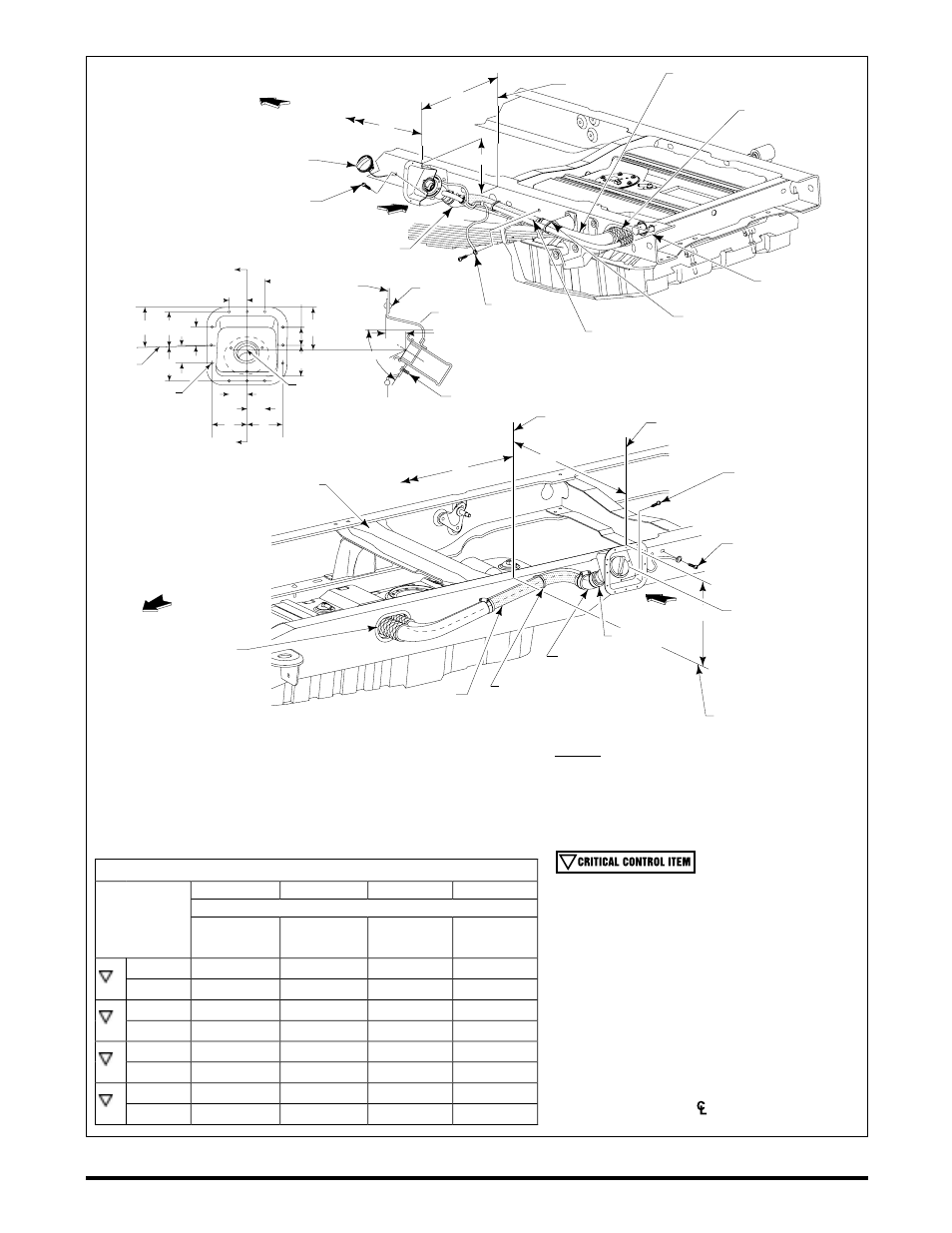

HOLE IN

MANUFACTURERS BODY

HOLES

3/16 INCH

BLIND RIVET *

(12 REQ’D)

87

[3.42]

78

[3.07]

48

[1.89]

48

[1.89]

78

[3.07]

48

[1.89]

48

[1.89]

105.7

[4.16]

67.5

[2.66]

48

[1.89]

81

[3.19]

616

[2.42]

75

POINT Z

SECTION U

U

U

VIEW P

B

FRONT OF

VEHICLE

48

[1.89]

48

[1.89]

81

[3.19]

C

REFER TO CALIFORNIA

FUEL VAPOR RECOVERY

REQUIREMENT.

VIEW P

C

D

C

D

L OF

BRACKET

MAINTAIN 25.4 [1.00] MINIMUM CLEARANCE

BETWEEN FUEL FILLER SYSTEM AND THE

SPRING AND SPRING SHACKLE IN ALL

DYNAMIC POSITIONS.

PROTECTIVE SLEEVES ARE

REQUIRED ON BOTH FILL

AND VENT HOSE AT FRAME

OPENING.

USE PROVIDED TIE STRAPS

TO SECURE FILL TO VENT

HOSES (2 PLACES)

A

FRONT OF

VEHICLE

VIEW P

USE PROVIDED TIE STRAPS

TO SECURE FILL TO VENT

HOSES (2 PLACES)

OUTBOARD SURFACE

OF FRAME RAIL

TOP OF FRAME RAIL

INSTALL GROUND

WIRE TO SOUND

METAL ON THE

SCREW (3 REQ’D)

TORQUE

1.7-2.8 NEWTON METERS

[15-25 IN. LB.]

#4 C/MEMBER

TO BACK

OF CAB

OUTBOARD SURFACE

OF FRAME RAIL

CL OF FILL PIPE ASY.

AND BRACKET

INSTALL GROUND WIRE

TO SOUND METAL ON

THE FRAME.

TOP OF FRAME RAIL

C

AT L OF FILL PIPE

SUB

SUPPORT

MIDSHIP FUEL FILL SYSTEM

AFT OF AXLE FILL SYSTEM

(OPTIONAL ON CHASSIS CAB)

PROTECTIVE SLEEVES ARE

REQUIRED ON BOTH FILL

AND VENT HOSE AT FRAME

OPENING.

STEEL TUBE

(DO NOT TRIM)

STEEL TUBE

(DO NOT TRIM)

SCREW (3 REQ’D)

TORQUE

1.7-2.8 NEWTON METERS

[15-25 IN. LB.]

FRAME.

THIS HOSE IS PREFORMED:

INSTALL SHORT END TO THE

METAL NECK AND CAP ASSEMBLY;

TRIM THE LONG END AS REQUIRED.

(12 PLACES)

THIS HOSE IS PREFORMED:

INSTALL SHORT END TO THE

METAL NECK AND CAP ASSEMBLY;

TRIM THE LONG END AS REQUIRED.

CAP

1/4 TURN - GASOLINE - LEV II

SCREW IN - DIESEL

CAP

1/4 TURN - GASOLINE - LEV II

SCREW IN - DIESEL

DO NOT TRIM

THIS END

NOTES:

TORQUE ALL WORM GEAR DRIVEN HOSE CLAMPS

TO 2.8 - 3.9 NEWTON METERS [25-35 IN. LB.]

[ ] DIMENSIONS ARE INCHES

* NOT SUPPLIED BY FORD MOTOR COMPANY

Remove and discard the Ford installed fuel fill system

components (provided for shipping purposes only) except

save and reuse the metal neck and cap assembly.

Use the new hoses, pipes, scuff guards, tie wraps, and

clamps provided in the dunnage kit.

The completed fuel fill system must provide a 4 degree

minimum, continuous, downward slope to the fuel tank.

Additional support may be required to prevent hose

sagging which could cause spray or spitback during

normal fueling operations.

Do not extend the fuel fill system outboard of the second

unit body.

The installation of Tube Extension F81A-9B149-HA will

permit the location aft-of-axle fuel fill housing to be no

further rearward than the of the fill hose as it passes

through the frame.

(CA) BACK OF CAB TO CENTERLINE OF REAR AXLE

60 INCH CA

84 INCH CA

108 INCH CA

120 INCH CA

WHEELBASE

Regular Cab

Super Cab

Crew Cab

3576mm [140.8]

4110mm [161.8]

4475mm [176.2]

4186mm [164.8]

5085mm [200.2]

4795mm [188.8] 5100mm [200.8]

MIN

864mm [34.0]

1473mm [58.0]

2083mm [82.0] 2388mm [94.0]

A

MAX

1029mm [40.5]

1638mm [64.5]

2248mm [88.5] 2553mm [100.5]

MIN

1981mm [78.0]

2591mm [102.0] 3200mm [126.0] 3505mm [138.0]

B

MAX

2159mm [85.0]

2769mm [109.0] 3378mm [133.0] 3683mm [145.0]

MIN

584mm [23.0]

584mm [23.0]

584mm [23.0]

584mm [23.0]

C

MAX

787mm [31.0]

787mm [31.0]

787mm [31.0]

787mm [31.0]

MIN

267mm [10.5]

267mm [10.5]

267mm [10.5]

267mm [10.5]

D

MAX

343mm [13.5]

343mm [13.5]

343mm [13.5]

343mm [13.5]

FIGURE A – SUPER DUTY F-SERIES NARROW FRAME CHASSIS CAB FUEL FILLER PIPE INSTALLATION