Frymaster FOOTPRINT PRO SERIES 35 User Manual

Page 18

2-8

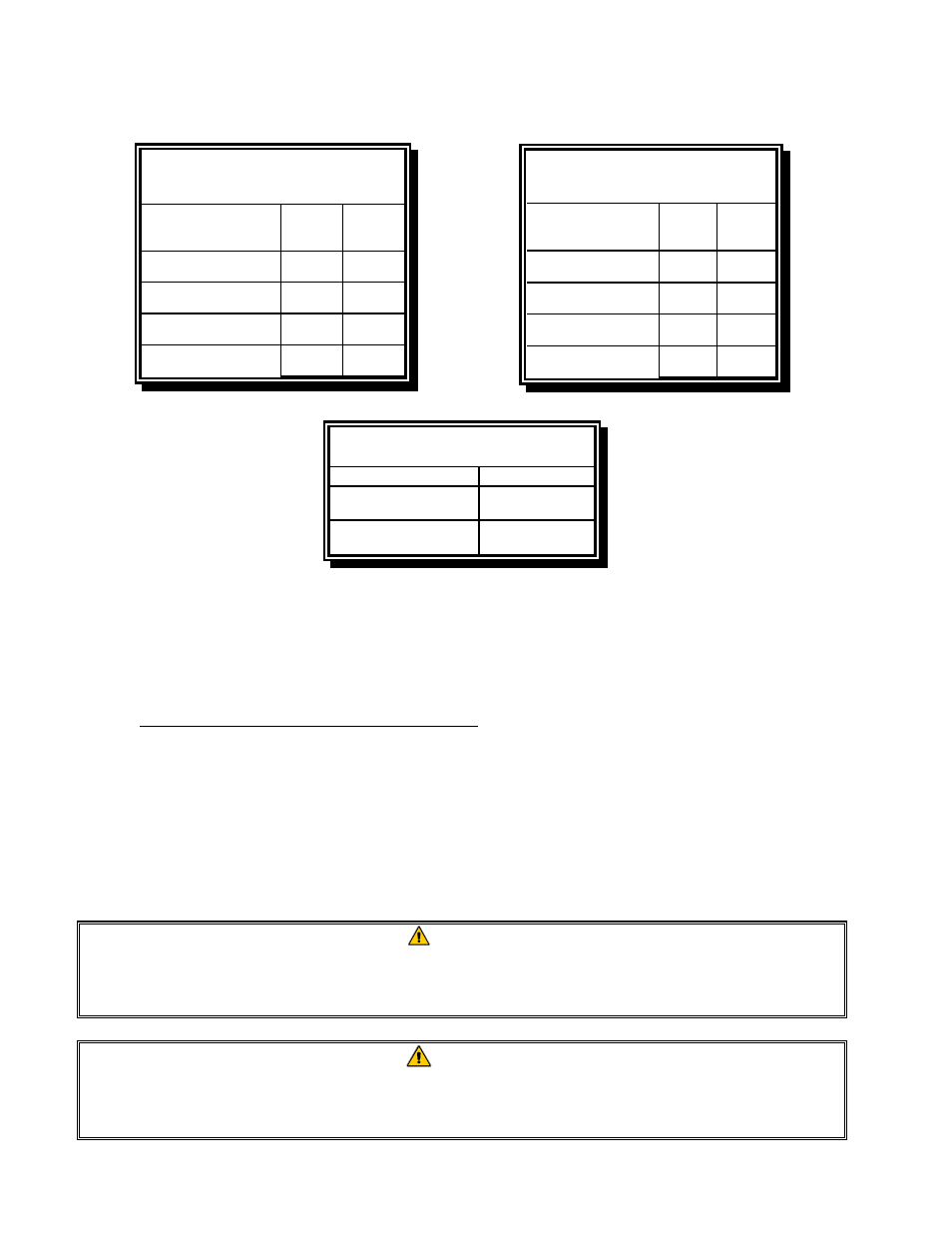

4. The burner manifold pressure should be checked at this time by the local gas company or an

authorized service agent. The tables below indicate the proper burner manifold pressures:

Gas

Model 35

Pressure

(mbar)

Model 45

Pressure

(mbar)

Natural Gas Lacq

(G20) under 20 mbar

9

7,5

Natural Gas Gronique

(G25) under 25 mbar

13,5

10

Natural Gas Gronique

(G20) under 20 mbar

13,5

10

Propane

(G31) under 37 or 50 mbar

22,5

20,6

Table 5: CE Standard

Burner Manifold Gas Pressures

(Other than Belgium)

Gas

Model 35

Pressure

(mbar)

Model 45

Pressure

(mbar)

Natural Gas Lacq

(G20) under 20 mbar

9

7,5

Natural Gas Gronique

(G25) under 25 mbar

9

7

Natural Gas Gronique

(G20) under 20 mbar

9

10

Propane

(G31) under 37 or 50 mbar

22,5

20,6

Table 6: CE Standard

Burner Manifold Gas Pressures

(Belgium)

Gas

Pressure

Natural

3" W.C.

0.73 kPa

LP

8.25" W.C.

2.5 kPa

Table 7: Non-CE Standard

Burner Manifold Gas Pressures

5. Check the thermostat calibration or temperature programmed into the computer.

•

For units equipped with thermostat controls, refer to the Thermostat Calibration instructions

in Chapter 5.

•

For units equipped with other types of controllers, refer to the appropriate section of the

Frymaster Fryer Controllers User’s Manual, provided with your equipment for instructions

on programming and operating your controller.

2.5

Converting to Another Gas Type

Your fryer is configured at the factory for either natural gas or Propane (LP) gas.

If you desire to switch from one type of gas to another, a gas conversion kit must be installed by a

Factory Authorized Service Center technician.

DANGER

This appliance was configured at the factory for a specific type of gas. Converting

from one type of gas to another requires the installation of specific gas-conversion

components.

DANGER

Switching to a different type of gas without installing the proper conversion kit may

result in fire or explosion! NEVER ATTACH THIS APPLIANCE TO A GAS SUPPLY

FOR WHICH IT IS NOT CONFIGURED!