Ch300 installation check sheet, Soundome cover removal and replacement – Furuno CH300 User Manual

Page 3

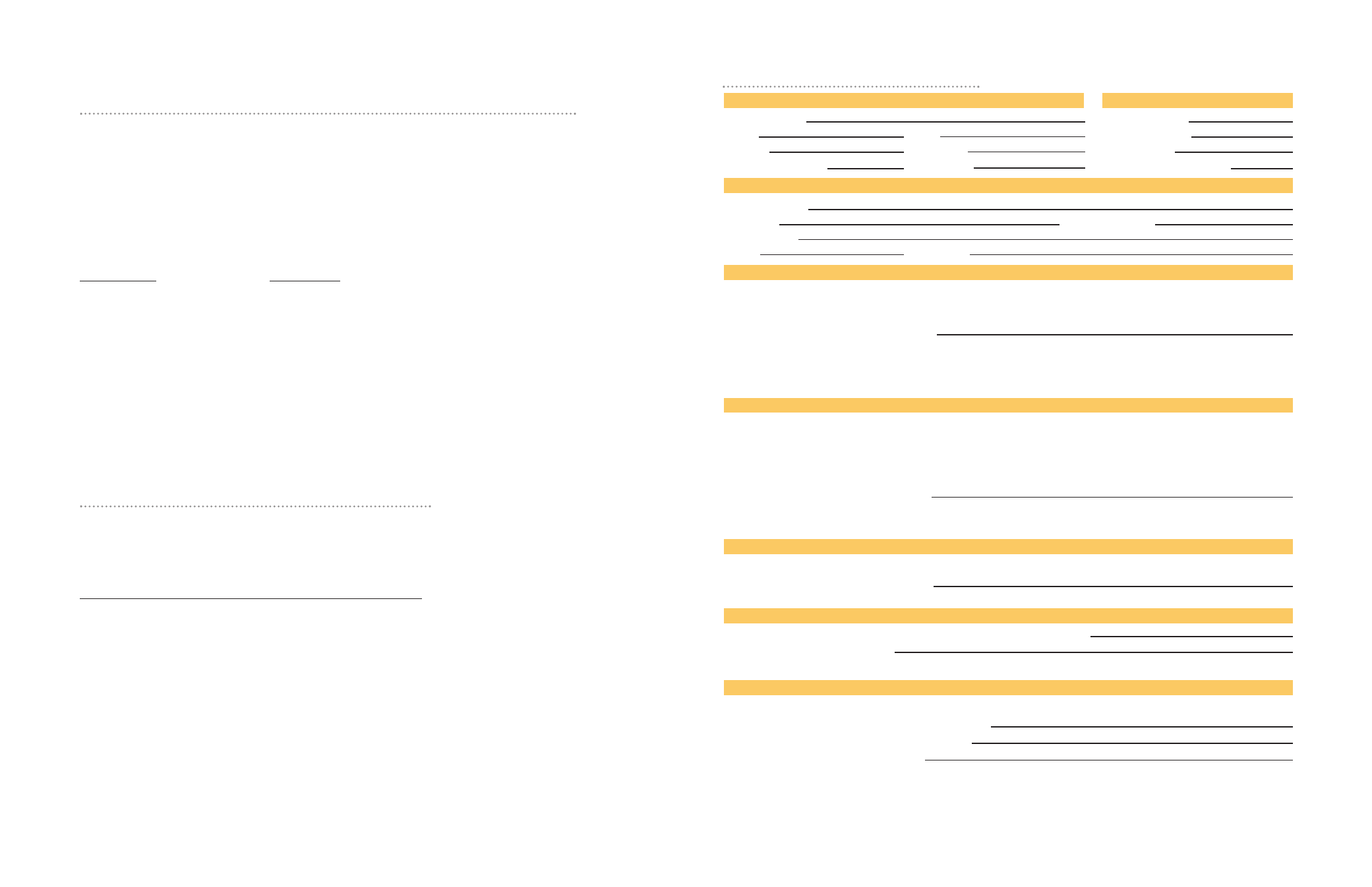

CH300 Installation Check Sheet

Vessel Information

CH300 System Information

Vessel Name:

CH300 Model:

Type:

Use:

Serial Number:

Length:

Registry:

Shaft Travel:

Operating Speed:

Hull Type:

System Input Voltage:

Dealer Information

Dealer Name:

Address:

City, State, Zip:

Installed By:

Date:

Location:

Standard System – MU100C Display Check List

Are all cables and connections tight & strapped?

❏

Yes

❏

No

Is NMEA data connected and activated?

❏

Yes

❏

No

What NMEA devices are connected:

Has CH302 control head installation & operation been checked?

❏

Yes

❏

No

Is the unit grounded properly?

❏

Yes

❏

No

OR

Black Box System – VGA Display Check List

Are all cables and connections tight & strapped?

❏

Yes

❏

No

Does the monitor display the correct color palette?

❏

Yes

❏

No

Are the IF8000 dip switches set correctly?

❏

Yes

❏

No

Is NMEA data connected and activated?

❏

Yes

❏

No

What NMEA devices are connected:

Has CH302 control head installation & operation been checked?

❏

Yes

❏

No

Is the unit grounded properly?

❏

Yes

❏

No

CH303 Transceiver Unit Check List

Are all cables and connections tight & strapped?

❏

Yes

❏

No

Check and note actual input voltage

Is the unit grounded properly?

❏

Yes

❏

No

Motion Sensor or Incinometer Check List

Which sensor is being used, BS704 or MS100 or Sat Compass?

Where is the sensor located?

Has the sonar been programmed to look for the sensor?

❏

Yes

❏

No

Sonar Tube Installation Check List

Was a Furuno supplied sonar tube used?

❏

Yes

❏

No

If not, what was the ID of the sonar tube used?

What is the actual length of the sonar tube?

Where is the sonar tube mounted?

Is the sonar tube on or off the vessels centerline?

❏

On

❏

Off

Has a sonar tube air venting system been installed?

❏

Yes

❏

No

Has a forward sonar tube fairing been installed?

❏

Yes

❏

No

Motion Sensors, Inclinometers and

Longer Interconnect Cables

This valuable accessory unit must be mounted correctly to obtain any benefit from it:

a) Select a mounting location that is dry and vibration free

b) The selected location should be as close to the sonar hoist unit as possible

c) Mount the unit level (only compensating for normal vessel trim)

d) Line the unit up "fore and aft" accurately

e) Mount the unit "right side up" only

If a longer interconnect cable assembly is required, the following options are available:

Part number

Description

MS1-CBL-15M

15 meter signal cable assembly

MS1-CBL-30M

30 meter signal cable assembly

MS1-CBL-50M

50 meter signal cable assembly

Note:

The MS100 compensates for any vessel pitching and rolling at sea. To properly set itself the

motion sensor must be powered up while the vessel is in a stable condition. This step is easi-

er to accomplish at the dock. Please get in the habit of powering up the entire CH300 system

prior to departing from the dock. This one easy step will ensure proper operation of the

MS100 and enhanced CH300 performance for the duration of the voyage.

Soundome Cover Removal and Replacement

Remember to detach or replace the soundome cover assembly, ONLY remove the 10

stainless steel Allen head cap screws! These are the cap screws that hold the soundome

cover assembly to the upper bronze housing.

The plastic cover cross head screws should never be touched! This cover has been factory

sealed and cannot be replaced in the field without destroying the soundome's watertight

integrity and warranty.

Once the soundome has been filled with oil, keep it in a vertical position to prevent any

internal seepage. If the soundome assembly has to be removed for repair or shipment, the oil

must always be removed.You may wish to retain the soundome packing material for future

use.

Page 1

Page 8