Fitting tool inserts – Festool RAS 115.04 E User Manual

Page 5

5

– Release the screw (4.1) on the clamping lever

and remove the lever (4.2).

– Tighten the square-headed screw (4.3) by hand

until a tension is obtained.

– Re-fi t the clamping lever and secure it with the

screw. The optimum clamping force can be de-

termined by closing the clamping lever before

the clamping screw is tightened.

b) Repositioning the rotatable handle

The rotatable additional handle can, if required,

also be fi tted to the right-hand side of the extrac-

tor hood. For this purpose, the handle and the

clamping lever should be interchanged.

– Release the screw (4.1) on the clamping lever

and remove the lever (4.2).

– Remove the square-headed screw (4.3).

– Detach the additional handle (4.5), using a 6 mm

A/F Allen key.

The clamping lever and the additional handle can

now be interchanged. Fitting is carried out in the

reverse of the above sequence. The locking nut

(4.4) can be used to vary the turning resistance

of the rotatable additional handle by tightening

the nut against the housing, using a 13 mm A/F

open-ended wrench, before fully tightening the

additional handle.

c) Replacing the brush insert

5.1

5.2

In order to replace this, press out the brush insert

by inserting a screwdriver through the square ap-

ertures (5.1). Insert the new brush strip (5.2) into

the groove, slightly bend this to obtain the correct

radius and press in fi rmly until the brush strip is in

contact with the base of the hood. The inclination

of the brush bristles must point outwards.

Two different brush inserts are available:

• AH-RAS D 115 Poly (484727): Pack of 2 polyam-

ide brushes (replacement for worn origi-nals)

• AH-RAS D 115 metal (484728): Pack of 1 metal

brush (for use with spark-generating materi-

als)

d) Sanding with dust extraction

For dust extraction, the suction hose (27 mm dia.)

of a Festool dust extractor should be inserted into

the connection socket (6.3) at the end of the ro-

tary sander housing.

6.3

6.1

6.2

The brush ring (6.2) can be adjusted by means of

the additional rotatable handle (6.1). This makes

it possi-ble to achieve an optimum setting for

the working position used. Always turn the brush

ring into the direc-tion of travel of the sanding

dust. A considerable quantity of air-borne sparks

are generated during the sanding of metals and

other spark-generating materials. For safety rea-

sons, therefore, a spark-trap (484733) must be

fi tted between the extractor hood and the rotary

sander.

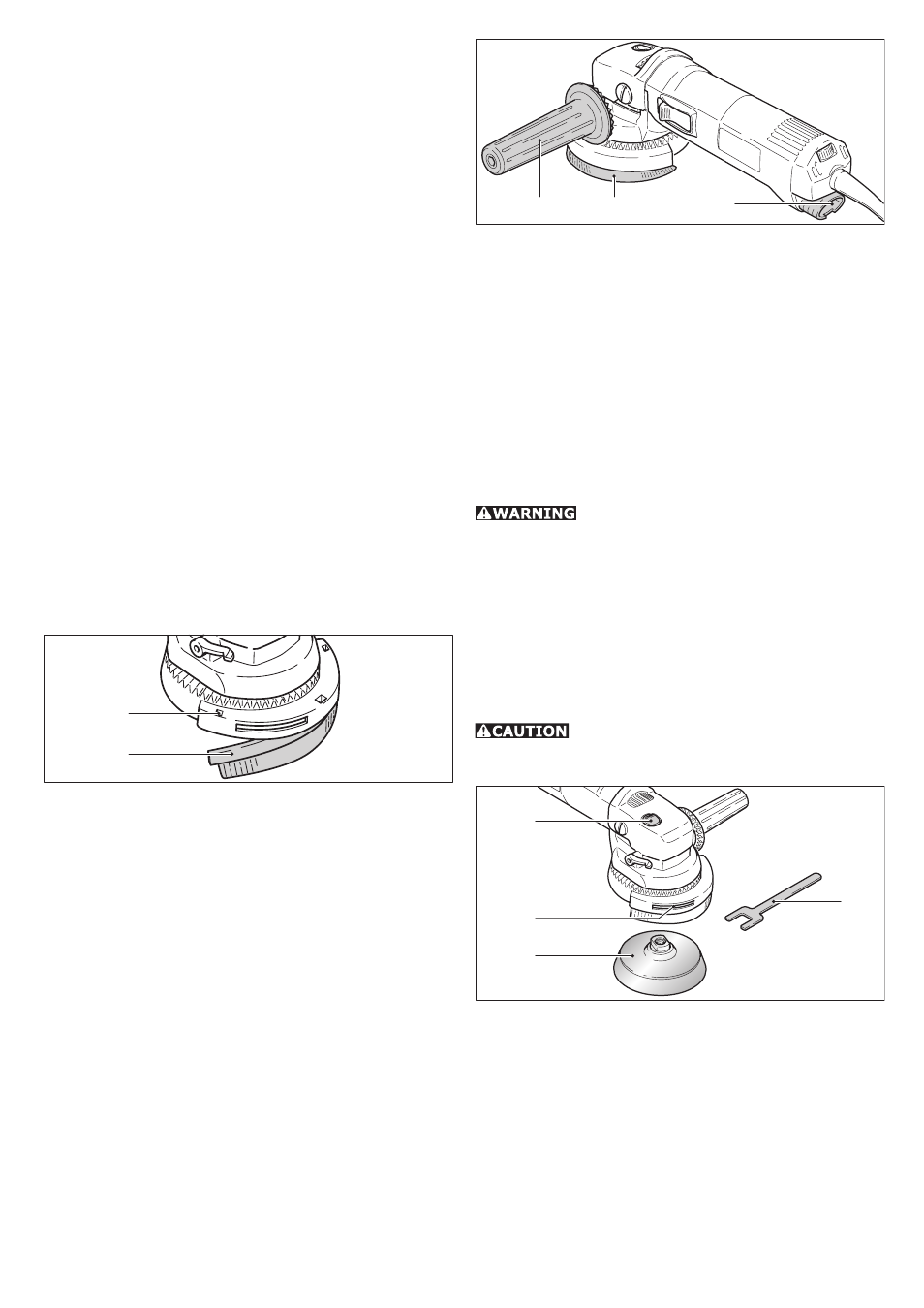

Fitting tool inserts

Use only tool inserts whose maximum

permissible speed is at least equal to the speed

given on the rating plate of the rotary sander. This

is the case with all original Festool accessories.

The Stickfi x sanding pads STF D 115 are provided

with an M 14 thread which enables these to be

screwed directly onto the drive spindle.

It is normally possible to unscrew the sanding pad

(7.3) by hand from the drive spindle after pressing

the spindle stop (7.1).

Actuate the spindle stop only when the

drive spindle is stationary. Do not switch on the

motor when the spindle stop is pressed in.

7.1

7.2

7.3

7.4

In case the pad should seize:

– Remove the brush insert.

– Insert the special spanner (7.4) through the slot

(7.2) and place on spanner fl ats of tool.

– Release the tool with the spindle stop pressed

by turning the special spanner.

Please note: Always screw the sanding pad onto

the drive spindle by hand. This will make it con-

siderably easier to remove it subsequently.