Changing the sawblade, Operation, Setting the blade depth – Festool ATF 55E User Manual

Page 12

Changing the Sawblade

Sawblade Checks and Warnings

►

Use only sawblades that are approved for use with the

saw, and appropriate for the type of material being cut.

►

Use only sawblades with a diameter of 160 mm, and an

arbor bore of 20 mm.

12

ATF 55E Circular Saw

►

Do not use a sawblade that is bent or warped.

►

Do not use a sawblade with missing or damaged teeth.

►

The hex hey provided with the saw is specifically designed

not to cam-out and damage the arbor bolt. Do not use a

standard Allen wrench or hex key.

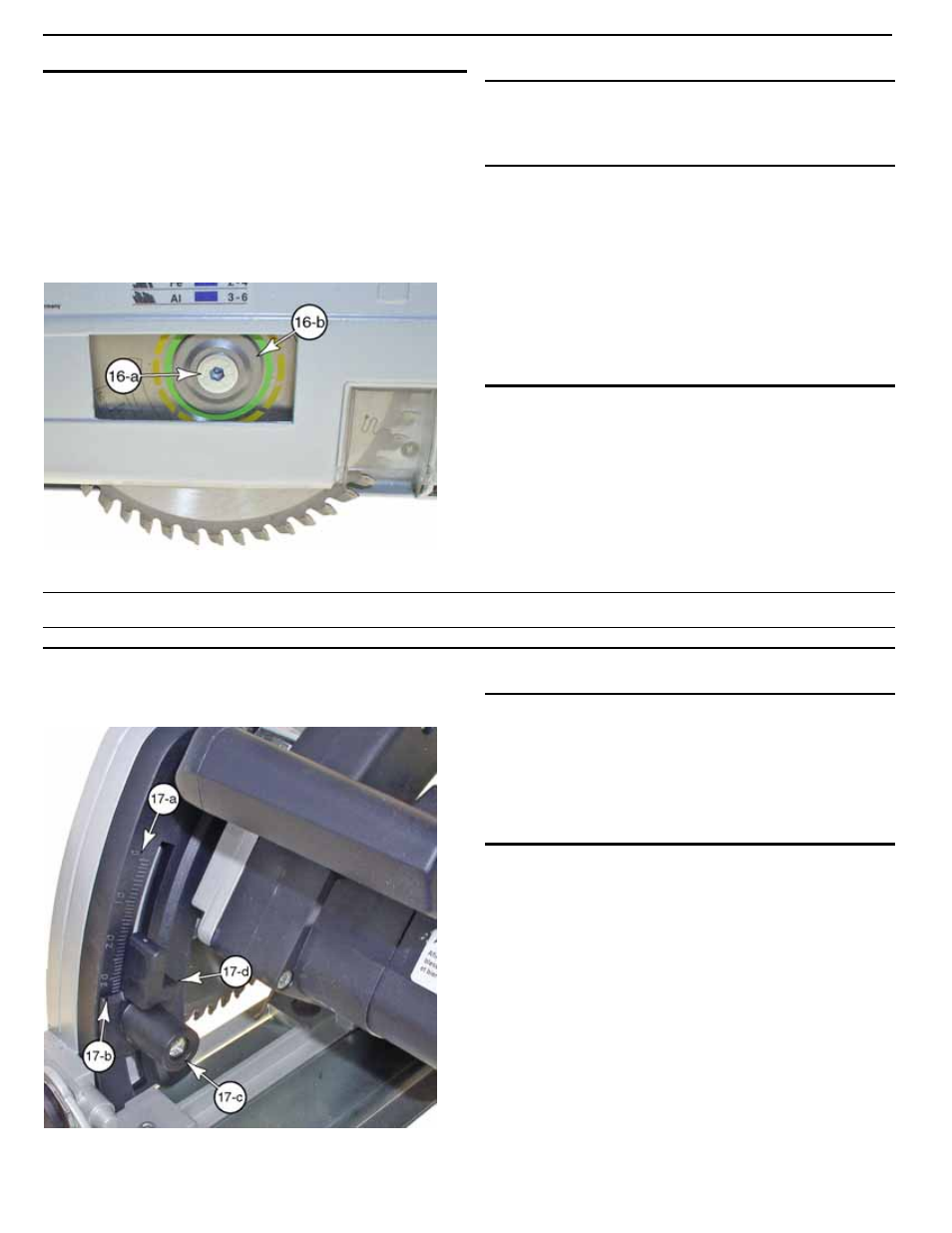

Figure 16

16-a Arbor Screw

16-b Arbor Flange

Removal Procedure

1.

Unplug the saw.

2.

Lower the blade until the arbor screw (16-a) is accessible

as shown.

3.

Press down on the arbor lock (figure 1-c).

4.

Using the hex key stored on the sole plate (figure 2-f),

unscrew the arbor screw by turning it counterclockwise

(standard thread), and remove the arbor screw (16-a)

and arbor flange (16-b).

5.

Remove the sawblade out the bottom of the saw.

Replacement Procedure

1.

Insert the new blade up through the bottom of the saw,

and place it on the arbor. Make sure the blade teeth are

pointing forward as shown.

2.

Place the arbor flange over the arbor, and rotate it until

the tabs line up with the slots in the arbor.

3.

Make sure the arbor and arbor flange are properly

seated with one another.

4.

Insert and tighten the arbor screw.

Operation

Setting the Blade Depth

The ATF 55 E is equipped with a plunging depth-stop for

setting the blade depth.

Figure 17

17-a Depth Gauge

17-b Pointer

17-c Lock Button

17-d Depth Stop

Adjustment Procedure

1.

Determine the optimal blade depth:

►

The depth of the blade is determined by the depth gauge

in millimeters (17-a).

►

For optimal chip-free cutting in plywood and hard

plastics, the sawblade should be slightly below the

bottom of the material (about ½ of a blade tooth).

►

For dense hardwoods, softer plastics, and aluminum

(where chipping is less of a concern) the blade should be

set a little deeper. At a deeper setting, the blade cuts

more efficiently.

2.

Push in on the lock button (17-c) and slide the depth

stop (17-d) to the desired depth.

►

Add 5 mm to account for the thickness of the guide rail.