3 frypot boilout – Frymaster Dean 2424E User Manual

Page 11

2-4

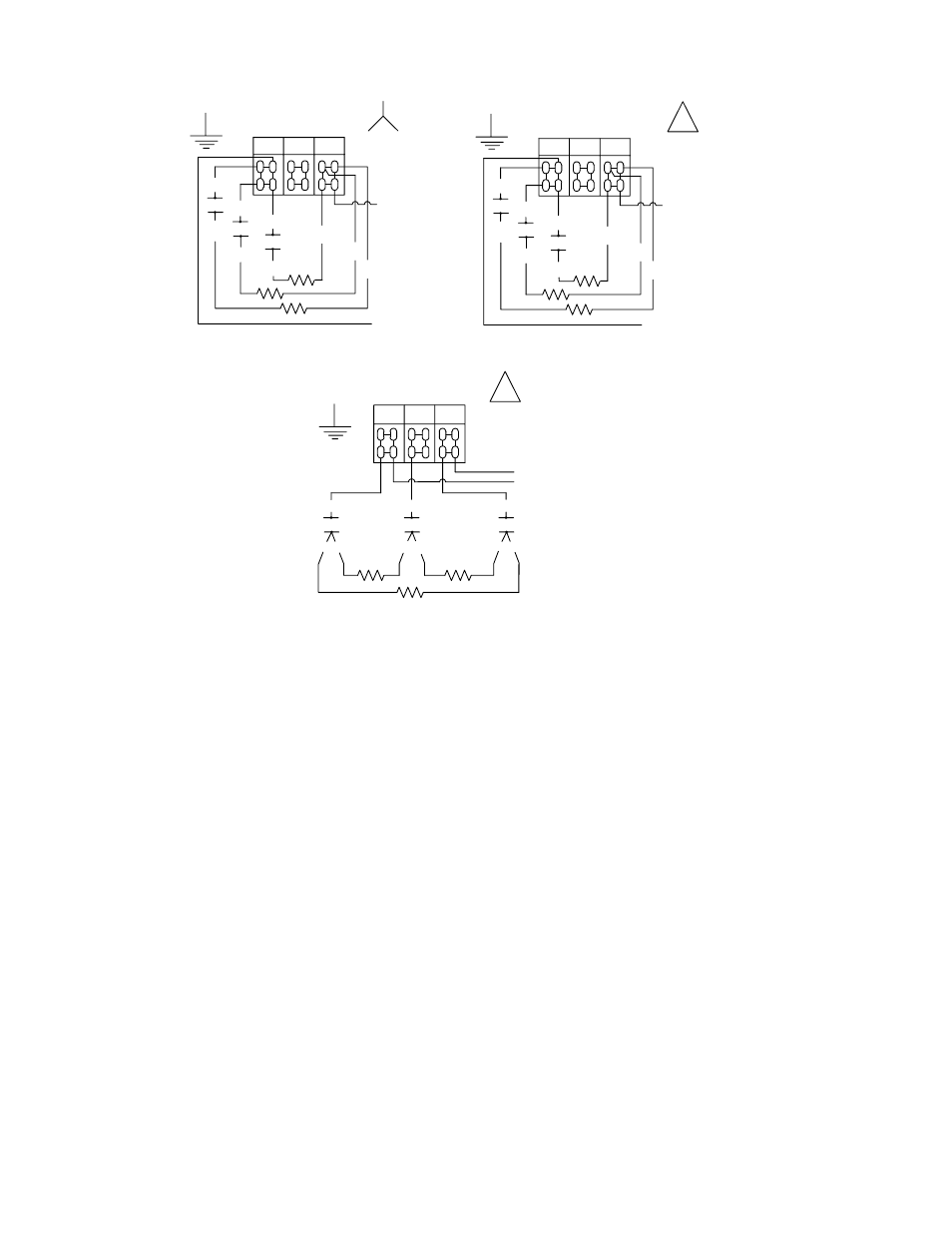

SINGLE PHASE (NO NEUTRAL)

FIELD CONNECTION

L1

L2

L3

1

1HV

1C1

2HV

1C2

2

3

3HV

1C3

4

5

6

FROM TRANSFORMER

FROM

TRANSFORMER

SINGLE PHASE

FIELD CONNECTION

NEUTRAL TO L3

L1

L2

L3

1

1HV

1C1

2HV

1C2

2

3

3HV

1C3

4

5

6

FROM TRANSFORMER

FROM TRANSFORMER

3 PHASE 3 WIRE (DELTA)

FIELD CONNECTION

L1

L2

L3

1HV

1C1

1

2

5

3

2HV

1C2

3HV

1C3

4

6

FROM TRANSFORMER

FROM TRANSFORMER

6. Boil out the frypot(s) in accordance with the Boilout procedure in Section 2.3.

2.3 Frypot

Boilout

Before the fryer is first used for cooking product, it should be boiled out to ensure that residue from

the manufacturing process has been eliminated.

Also, after the fryer has been in use for a period of time, a hard film of caramelized vegetable oil will

form on the inside of the frypot. This film should be periodically removed by following the boilout

procedure.

Boilout the frypot(s) in accordance with the procedure below before filling with cooking oil or

shortening for the first time and at least once a month thereafter:

1. Verify that the frypot drain valve is closed, and then fill the empty frypot with a mixture of cold

water and detergent. Follow the instructions on the detergent container when mixing.

2. If this is the first time the fryer is being operated after installation, set the operating thermostat

or optional solid-state controller to 225°F (110°C), then press the POWER switch to the POWER

position. If the fryer is so equipped, press the FRYER RESET switch for a couple of seconds

then release it. If the light in the reset switch does not remain lit when the switch is released,

verify that the drain valve is fully closed, and then press the reset switch again. NOTE: On