Warning, I. operational checkup, J. troubleshooting – Franklin Water Pump User Manual

Page 8: Floatless liquid level control, Hazardous voltage- can shock, burn, or even kill

FLOATLESS LIQUID LEVEL CONTROL

The sensing elements of a fl oatless liquid level control

consists of 2 electrodes suspended in the well by

insulated wires. These wires connect to a relay which

serves as a pilot switch to the starting equipment. The

lower electode is set just above the pump, and the upper

at some distance below the static water level. The device

cuts off power to the pump automatically when the water

level drops below the lower electrode, and does not

restore power until the water level recovers to reach the

upper electrode. The Liquid Level Control can also be

used as a pilot switch in connection with elevated tanks

.

I. OPERATIONAL CHECKUP

The most reliable indication of the condition of a

submersible pump are:

(a) The current drawn by the motor

(b) The insulation resistance of the installation

below ground.

As the pump wears, the motor current increases, until

eventually the overloads trip to protect the motor. While

this automatic protection looks after an emergency

situation, proper care of a submersible installation should

include perioodic check-ups to avoid interruptions in

the water supply. Use a megger to check the insulation

resistance every six months.

Record the insulation resistance and the running current

for future reference. When the insulation resistance

fall below 10 Megohms, check it frequently for further

deterioration and pull the pump when the resistance falls

to 1/2 megohm.

When pulling the pump, either coil the cable on a reel

or raise it from the ground to dry. Check the insulation

again when the cable and splices are dry. If the insulation

value is between the line and motor casing increases

to 50 megohms or more, isolate the fault in the cable or

the splice and make the necessary repairs. However, if

the insulation reading remains low, disconnect the motor

from the cable and check the motor separately. Should

the motor be defective, check the pump end for wear and

obtain a replacement for either the motor alone, or the

pump unit, as necessary.

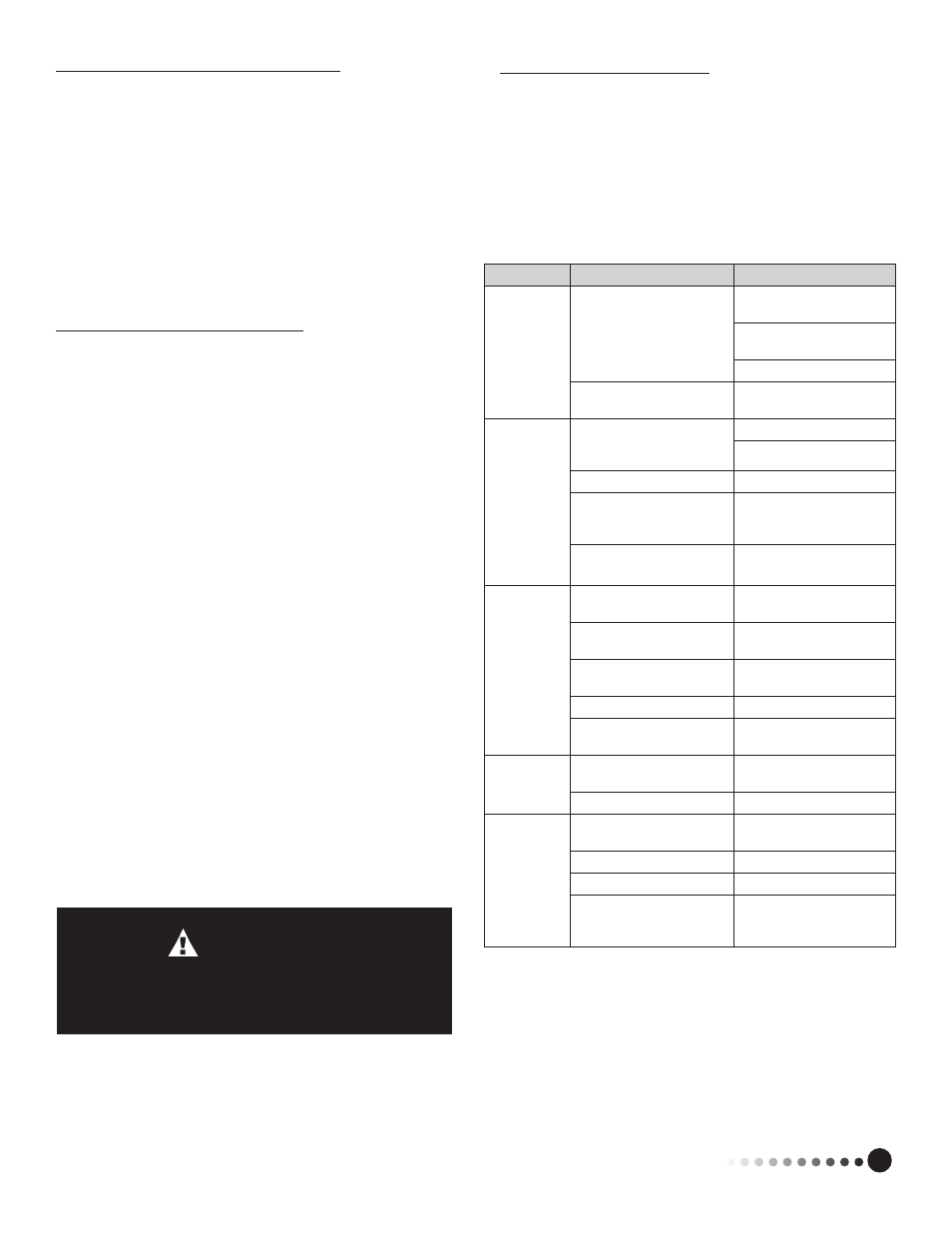

PROBLEM

POSSIBLE CAUSE

REMEDY

Unit fails

to start

1. Electrical trouble

Check Power source:

starter & reset

Check resistance:

cable and motor

Call Dealer or Electrician

2. Pump Sandlocked

Call Dealer: pull pump

and clean

Pump fails

to deliver

water

1. Insuffi cient well yield:

water level has dropped.

Reset pump lower into well

Restrict fl ow to yield

2. Clogged intake screen

Pull pump

3. Air Lock in pump

Start and stop pump

several times and allow 1

min. between

4. Leak in discharge

Raise pipe until leak is found.

Reduced

pump

output

1. Screen or pump partly

plugged

Pull pump and clean

2. Insuffi cient well yield

Check water level: lower

pump if permissible.

3. Worn pump - excessive

wear due to abrasives.

Replace worn parts

4. Low voltage

Call Electrician

5. Three Phase unit

running backward

Reverse rotation

Overload

trips

1. Worn pump or pump

bound by sand

Pull pump and clean or

replace worn parts.

2. Electrical trouble

Call Dealer or Electrician

Unit cycles

too

frequently

1. Pressure switch out of

adjustment

Readjust to correct setting

or replace

2. Leaks in service line

Locate and correct

3. Check valve leaking

Replace

4. Water logged tank

Check tank for leaks be

sure fi ttings are functioning

properly.

WARNING

HAZARDOUS VOLTAGE- CAN SHOCK, BURN,

OR EVEN KILL.

J. TROUBLESHOOTING

1. Disconnect power unless required for testing.

2. Have electrical testing done by a qualifi ed electrician.

3. Most problems occur above ground. Remove pump

only as a last resort.

When troubleshooting or servicing the pump, use all

precautions for the voltages involved.

7