Frymaster GF14 User Manual

Page 10

1-6

1.7.4 Replacing the Gas Valve

DANGER

Drain the frypot or remove the handle from the drain valve before proceeding further.

1. Disconnect fryer from the gas supply.

2. Disconnect the wiring from the gas valve terminal block, marking each wire to facilitate

reconnection.

3. Disconnect the pilot gas line fitting from the gas valve and remove the vent tube.

4. GF14: Disconnect the pipe union to the right of the gas valve and rotate the valve assembly

outward just enough to allow the valve to be unscrewed from the burner manifold piping.

GF40: Disconnect the pipe unions at each side of the gas valve and remove the valve from the

assembly.

5. Remove the fittings from the old gas valve and install them on the replacement valve, using

Loctite™ PST56765 or equivalent pipe thread sealant on threads. Install the vent tube removed

from the old valve. DO NOT use thread sealant on the vent tube.

6. Reverse steps 1-4 to install the replacement valve, reconnecting the wiring in accordance with

the wiring diagram on the door of the fryer or with the notes made in Step 2. Return the fryer to

operation and check the burner manifold pressure, as detailed below.

7. Ensure that the gas valve knob is in the OFF position.

8. Remove the pressure tap plug from burner manifold.

9. Insert the fitting for a manometer or pressure gauge into the pressure tap hole.

10. Place the gas valve in the PILOT position and light the pilot. When the pilot lights and

continues to burn, increase the setting on the thermostat knob until the burner lights. Compare

the manometer or gauge reading to the appropriate table below.

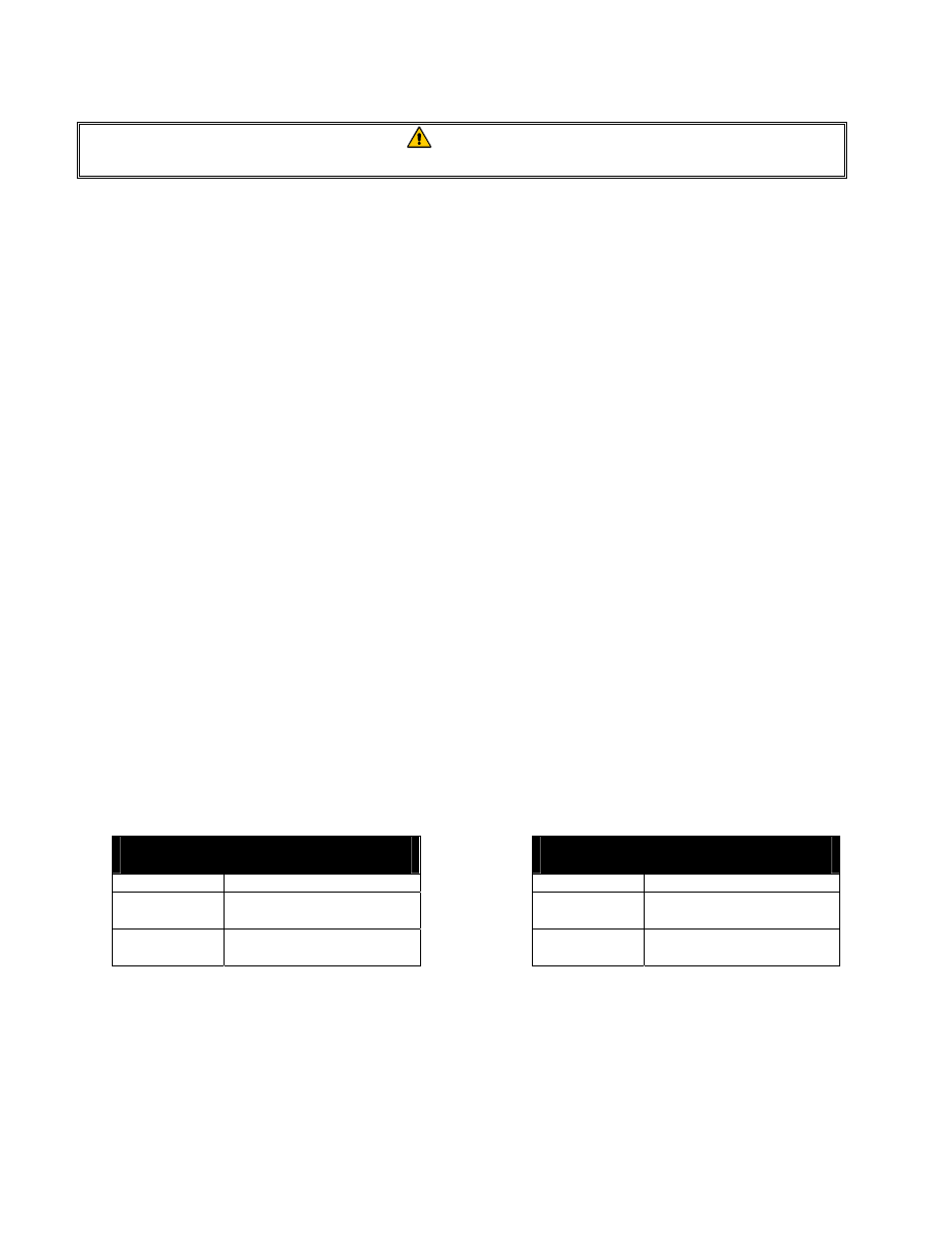

GF14 Standard

for Burner Manifold Pressure

Gas Type

Pressure

Natural

4.0” WC

(1.00 kPa or 9.96 mbar)

LP

10.0” W.C

(2.49 kPa or 24.91 mbar)

GF40 Standard

for Burner Manifold Pressure

Gas Type

Pressure

Natural

3.5” WC

(0.87 kPa or 8.72 mbar)

LP

8.25” W.C.

(2.06 kPa or 20.55 mbar)

11. If the burner manifold pressure does not meet the specifications in the tables in Step 4, unscrew

the slotted cap from the top of the gas valve regulator (adjacent to the gas valve vent tube) and

turn the adjusting screw to obtain the correct pressure. Turn the screw clockwise to increase

pressure, counter-clockwise to decrease pressure.

12. After adjusting the manifold pressure to the correct value, reinstall the regulator cap and turn the

gas valve knob to the OFF position.