Assembly & operation – Fantom Vacuum FANTOM PT302H User Manual

Page 13

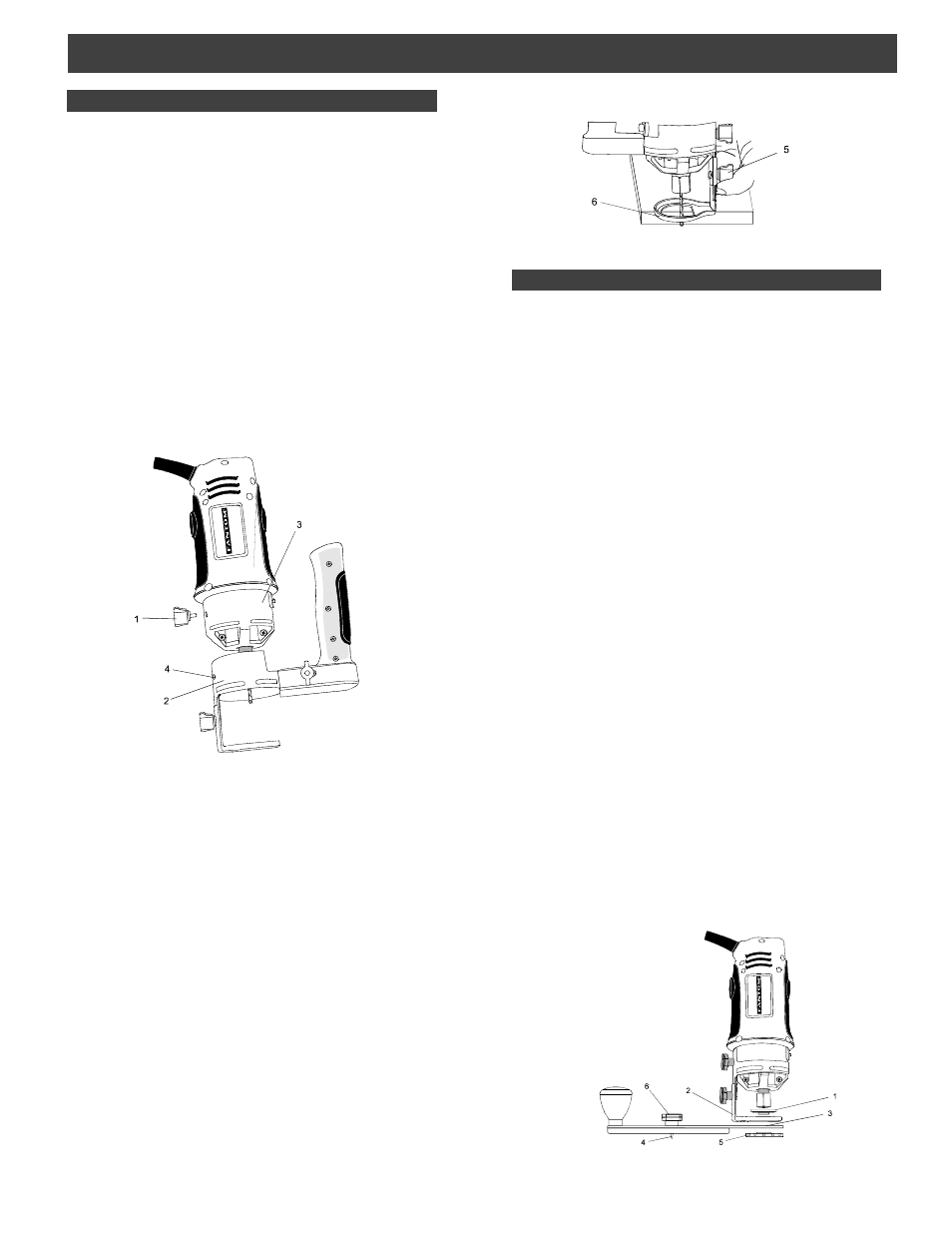

INSTALLING PRECISION HANDLE

The precision handle is designed for use when precision

control over the tool movement is desired. The

comfortable handle can be used with either the right or left

hand.

1. Remove accessory locking knob (1) from the base of

the

Rotary Tool motor housing (see Fig. 10). Slide

precision handle mounting bracket (2) onto the bottom

of motor housing (3) until the mounting hole (4) lines

up with the hole in the motor housing.

NOTE: The tab on the side of the precision handle

mounting bracket must be inserted into the matching

slot in the motor housing.

2. Re-insert accessory locking knob into the motor

housing and securely tighten.

ADJUSTING FREEHAND SOLE PLATE

1. Adjust precision handle sole plate depth, by loosening

the depth gauge knob (5) and sliding the sole plate (6)

in or out as required (see Fig. 11).

NOTE: Set the depth gauge so the cutting bit

protrudes beyond the sole plate

1

/

8

” more than the

thickness of the material being cut. For example, if

you are cutting

3

/

4

” pine, the bit should protrude

7

/

8

”

beyond the sole plate.

2. Securely tighten depth gauge knob.

3. Before starting to cut you should re-check bit depth,

make sure sole plate is at right angles to the bit and

securely tightened. Re-check the collet to make sure

the bit is securely fastened.

ADJUSTING FREEHAND SOLE PLATE – Cont’d

INSTALLING CIRCLE CUTTER

The circle cutter accessory is ideal for precision cutting of

circles. This circle cutter can be attached to either the

freehand sole plate or the precision handle sole plate. For

purposes of illustration, the circle cutter is shown with the

freehand sole plate.

1. Install freehand sole plate on the tool as illustrated on

Page 10 of this Owner’s Manual.

2. Insert the externally threaded circle cutter mounting

insert (1) into the bottom of the sole plate (2) (see

Fig. 12).

NOTE: Make sure the “D”

shaped opening in the

mounting insert is inserted into the matching “D”

shaped opening in the sole plate.

3. Place circle cutter mounting hole (3) over the

externally threaded circle cutter mounting insert.

NOTE: Make sure pointed pivot pin (4) is pointing

away from the tool.

4. Screw the internally threaded circle cutter mounting

disc (5) onto the externally threaded circle cutter

mounting insert and hand tighten.

NOTE: Do not over tighten the circle cutter mounting

plastic parts. Hand tighten only.

5. Adjust the circle cutting radius by loosening pivot point

knob (6), sliding it to the correct circle radius and re-

tightening in the desired location.

NOTE: Check circle cutter radius setting by

measuring from the pivot point to the outside of the

cutting bit.

Fig. 11

Fig. 10

Fig. 12

ASSEMBLY & OPERATION

PRECISION HANDLE

CIRCLE CUTTER

13