Model, Page 10 – Five Star JHP User Manual

Page 10

Page 10

3.2 Electrical

Installation

3.2.1 Voltage

Checks

The correct voltage, as specified on the pump data

plate, is necessary for proper performance and long

motor life. Incorrect voltage will decrease the pump's

ability to perform and could cause overheating, reduce

the motor life, and result in higher electric bills.

It is the responsibility of the electrical installer to

provide data plate operating voltage to the pump by

ensuring proper circuit sizes and wire sizes for this

specific application.

CAUTION

Failure to provide data plate voltage (within 10%)

during operation will cause the motor to overheat

and void the warranty.

3.2.2 Bonding and Grounding

1.

The motor frame must be bonded to a reliable

grounding point using a solid copper conductor,

No. 8 AWG or larger. In Canada, No. 6 AWG or

larger must be used.

2. Bond the motor using the provided external

lug.

WARNING

Always disconnect the power source before

working on a motor or its connected load.

WARNING

Ensure that the control switch or time clock is

installed in an accessible location so that in the

event of an equipment failure or a loose plumbing

fitting the equipment can be turned off. This

location must not be in the same area of the pool

pump, filter, and other equipment.

CAUTION

The pump must be permanently connected to a

dedicated electrical circuit. No other equipment,

lights, appliances or outlets may be connected

to the pump circuit.

3.2.3 Electrical

Wiring

1.

The pump motor must be securely and adequately

grounded using the green screw provided.

Ground before attempting to connect to an

electrical power supply. Do not ground to a gas

supply line.

2.

Wire size must be adequate to minimize voltage

drop during the start- up and operation of the

pump. See Table 2 for suggested wire sizes.

3. Insulate all connections carefully to prevent

grounding or short-circuits. Sharp edges on

terminals require extra protection. Tape wire

nuts to prevent loosening. For safety, and to

prevent entry of contaminants, reinstall all

conduit and terminal box covers. Do not force

connections into the conduit box.

4.

To configure the pump motor internal wiring for

the correct voltage, refer to the diagram on the

motor data plate.

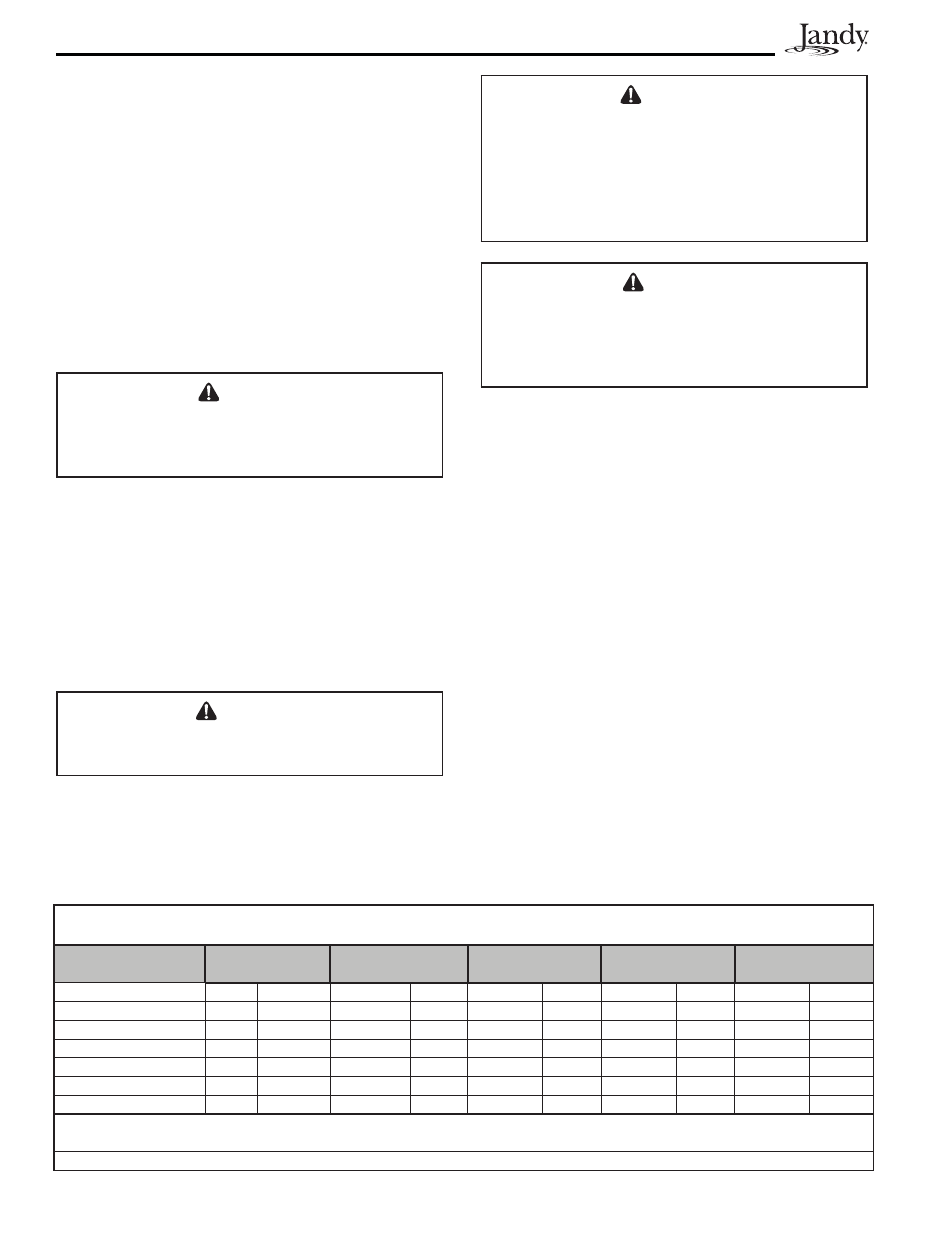

RECOMMENDED MINIMUM WIRE SIZE FOR SHP PUMPS*

DISTANCE FROM SUB-PANEL

Model

BRANCH FUSE AMPS

0-50 FEET

50-100 FEET

100-150 FEET

150-200 FEET

230

115

208-230 VAC

115 VAC 208-230 VAC 115 VAC 208-230 VAC 115 VAC

208-230 VAC

115 VAC

SHPF.75HP/SHPM1.0HP

15A

15A

14

12

12

8

10

6

8

6

SHPF1.0HP/SHPM1.5HP

15A

20A

12

10

10

8

8

6

6

4

SHPF1.5HP/SHPM2.0HP

15A

NA

12

NA

10

NA

8

NA

6

NA

SHPF2.0HP/SHPM2.5HP

15A

NA

12

NA

8

NA

6

NA

6

NA

SHPF3.0HP

20A

NA

10

NA

8

NA

6

NA

4

NA

SHPM2.0HP-2-SPEED (1)

15A

NA

12

NA

8

NA

6

NA

6

NA

SHPM2.5HP-2-SPEED (1)

15A

NA

12

NA

8

NA

6

NA

6

NA

*ASSUMES THREE COPPER CONDUCTORS IN A BURIED CONDUIT AND 3% MAXIMUM VOLTAGE LOSS IN BRANCH CIRCUIT. ALL NEC AND LOCAL

CODES MUST BE FOLLOWED. TABLE SHOWS MINIMUM WIRE SIZE AND BRANCH FUSE RECOMMENDATIONS FOR TYPICAL INSTALLATION PER NEC.

(1) TWO SPEED PUMPS ARE NOT RATED FOR USE WITH 208 VAC