Operation, Preparation – Husky hds790 User Manual

Page 3

26 Sp

1

2

3

4

5

6

7

8

9

10

11

12

14

15

17

18

19

20

23

26

27

28

29

30

31

32

14

13

16

24

25

21

22

Para Ordenar Repuestos o Asistencia Técnica, Sírvase Llamar al

Distribuidor Más Cercano a Su Domicilio

Sírvase darnos la siguiente información:

- Número del modelo

- Número de Serie o código con fecha (de haberlo)

- Descripción y número del repuesto según la lista de repuestos

Puede escribirnos a:

Attn: Customer Service

100 Production Drive

Harrison, OH 45030 U.S.A.

Manual de Instrucciones y Lista de Piezas

Pistola Pulverizadora HVLP Alimentada por Gravedad

34

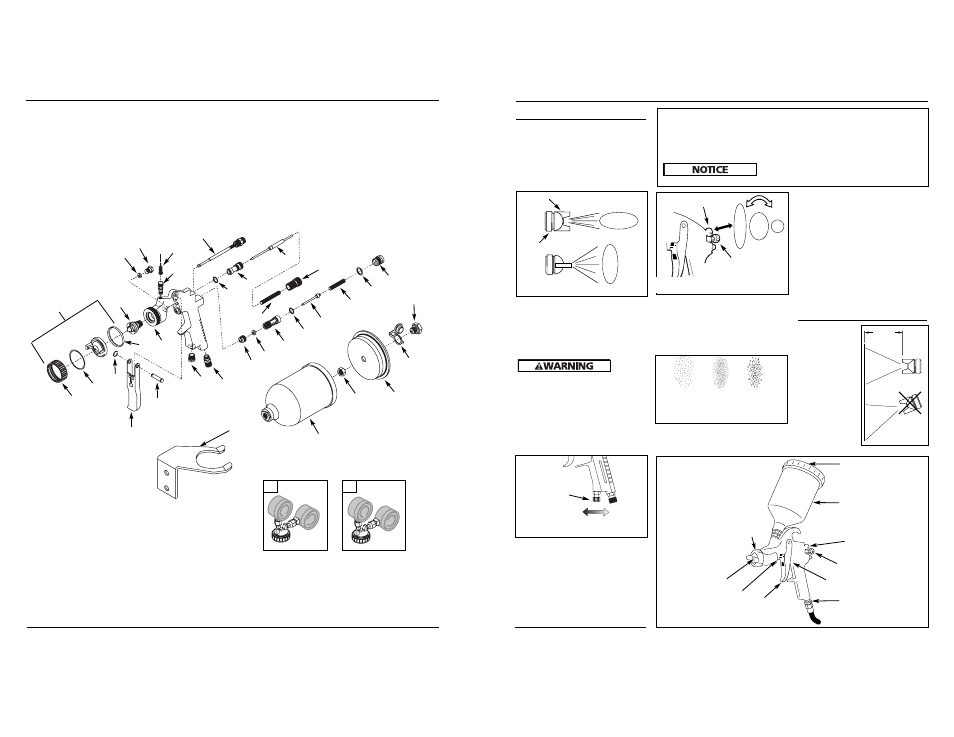

FAN DIRECTION

The direction of the fan (horizontal or

vertical) can be changed by loosening

the lock ring and turning the air cap 90

degrees (See Figure 3). Hand tighten

lock ring after adjustment.

PATTERN ADJUSTMENT

1. Adjust air pressure to the spray gun

according to the recommendations

supplied with the spray material.

This air pressure usually falls

between 40 - 60 psi.

Do not

exceed

spray gun maximum pressure.

Adjust air pressure with the trigger

pulled and air control knob (if applic-

able) fully open. If reduced air pres-

sure is desired for some areas of the

spray job, use the air compressor reg-

ulator or air control knob to reduce

pressure as necessary (See Figure 4).

2. Set pattern size to desired shape.

For full pattern, open pattern con-

trol knob by turning counterclock-

wise. For a round pattern, turn pat-

tern control knob clockwise

(See Figure 5).

3. Turn fluid control knob fully clock-

wise until closed (See Figure 5).

4. Trigger a short burst while turning

fluid control knob counterclockwise.

Observe the spray pattern on the tar-

get and adjust the fluid control knob

until the desired pattern (atomiza-

tion) is obtained (See Figure 6).

If the spray is too fine (excessive over-

spray), caused by too much air for the

amount of paint being sprayed, reduce

the air pressure or open the fluid con-

trol to spray more material.

If the spray is too coarse (spitting globs),

reduce the amount of material with the

fluid control knob or thin the paint.

5. The fluid control knob can be used

to finely adjust pattern consistency.

Before spraying the workpiece, practice

a few minutes on a cardboard target to

ensure the pattern size and consistency

are set correctly.

Operation

1. Begin spraying.

Always keep

the gun at

right angles to

the work (See

Figure 8).

2. Keep the noz-

zle about 6 to

9 inches from

the work sur-

face through-

out the stroke

and always

keep the gun

WATER/OIL IN COMPRESSED AIR

All compressor pumps discharge some condensed water, oil or contaminates with

the compressed air.

IMPORTANT: This condensation will cause “fish eyes” to appear in the paint

job. Install appropriate water/oil removal equipment and controls as necessary

for the intended application. Locate filter as close to spray gun as possible.

Failure to install appropriate water/oil removal

equipment may result in damage to machinery or

workpiece.

Operating Instructions and Parts Manual

HVLP Gravity Feed Spray Gun

Figure 3

Horizontal Fan

Vertical Fan

Air Cap

Lock Ring

Figure 4 - Air Adjustment on Spray Gun

Increase

Air Flow

Decrease

Air Flow

Air Control

Knob

Figure 5 - Pattern Size

Pattern control knob

Fluid control

knob

Figure 7 - Gravity Feed Spray Gun

Vent Hole

Fluid Control Knob

Trigger

Fluid Tip (Nozzle)

Pattern Control Knob

Cup

Air Cap

1/4” NPS Air Inlet Fitting

Fluid Packing Nut

Air Valve Packing Nut

3

Correct

Paint too

coarse

Paint too

fine

Figure 6 - Pattern Consistency

(Atomization)

Preparation

(Cont.)

6 - 9”

Figure 8

33

Juego de tapa de prueba HVLP

Los juegos de recipiente de prueba no

incluyen manómetros. Es necesario comprar

por separado un juego de manómetros de

baja presión certificados, de 1/8” NPT.

36

1.6 mm

1.4 mm

35