Changing the debris shield – HONDA HHT35S User Manual

Page 23

23

Blade Removal and Installation

For loop handle models, a special optional Barrier Kit must be

installed before a blade can be used. Refer to the instructions

provided with each kit on how to install a blade on loop handle

models.

Always wear gloves and install the blade cover on the blade when

working around the blade.

A torque wrench is required to install the blade. If you do not have a

torque wrench, have a Honda trimmer servicing dealer tighten the

blade lock nut for you before using the trimmer.

If the blade lock nut is tightened too much, the output shaft can break.

If the blade lock nut is not tightened enough, the blade could come off.

In either case, it would be possible for the blade to fly off while you are

operating the trimmer.

The blade lock nut is specially designed for this application. When

replacing the lock nut, use only a Honda Genuine replacement lock

nut.

BLADE SHARPENING: To avoid weakening the blade or causing

imbalance or poor cutting, the blade should be sharpened by trained

staff at a Honda trimmer servicing dealer.

BLADE REPLACEMENT: Your Honda trimmer servicing dealer has

cutting attachments that have been designed and approved for your

trimmer and are covered by a warranty. Non-Honda attachments are

usually designed for universal applications. Although aftermarket

attachments may fit on your trimmer, they may not meet factory

specifications and could make your trimmer unsafe.

1. Install the protective plastic cover that came with the blade.

2. Insert a commercially available 4 mm hex tool or equivalent fully

into the gear case hole.

3. Turn the blade until you feel the tool drop into the hole in cover

plate/spacer A. Verify the blade does not turn. The output shaft and

blade lock nut have a left-hand thread. Make sure the tool remains

in the hole, then loosen the blade nut as shown. Pay attention to

the order and orientation of the parts as they are removed.

4. Installation is the reverse of removal. Make sure you install the

blade with the cutting edges in the direction of rotation. Be sure to

align the hole in the blade with the shoulder on cover plate/spacer

A. Tighten the blade nut to the specified torque.

TORQUE: 14 ft-lb (20 N·m)

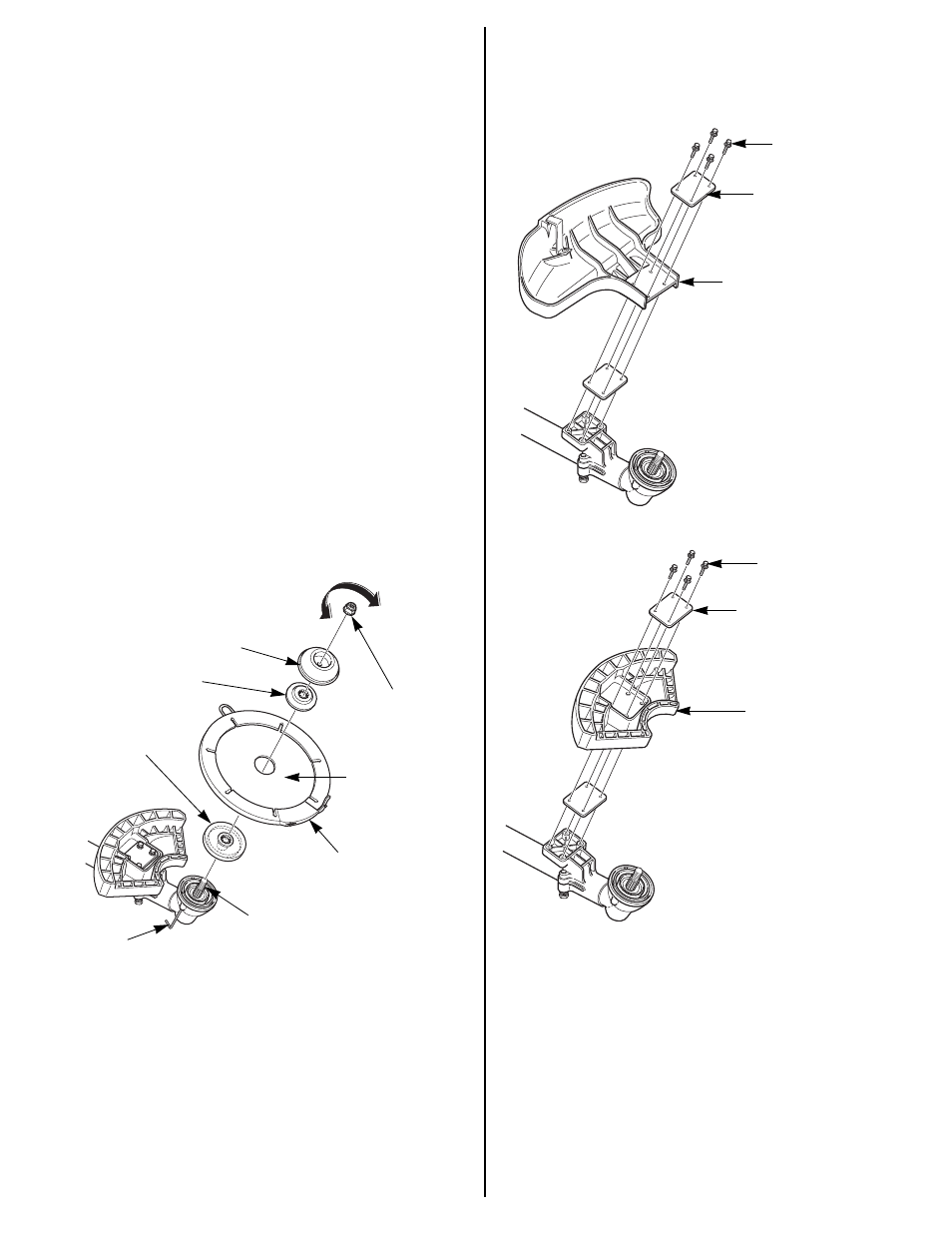

Changing the Debris Shield

Refer to the applicable illustration for removing and installing the

debris shields. Tighten the spacer bolts/washers to the specified

torque.

TORQUE: 2.5 ft-lb (3.4 N·m)

4 mm HEX

TOOL

SPACER B

COVER PLATE/

SPACER A

BLADE

10 mm LOCK NUT

(left-hand thread)

COVER

OUTPUT SHAFT

(left-hand thread)

LOOSEN

TIGHTEN

BLADE

COVER

CUTTING-LINE

DEBRIS SHIELD

(with cutoff knife)

5 x 28 mm

BOLT/WASHER (4)

SPACER (2)

[3/32" (2.30 mm)

thick]

BLADE DEBRIS

SHIELD

5 x 28 mm

BOLT/WASHER (4)

SPACER (2)

[3/32" (2.3 mm) thick]