Installation, Mechanical, Plumbing connections for self cleaning – FloAire Fully Integrated Self Cleaning System User Manual

Page 6

6

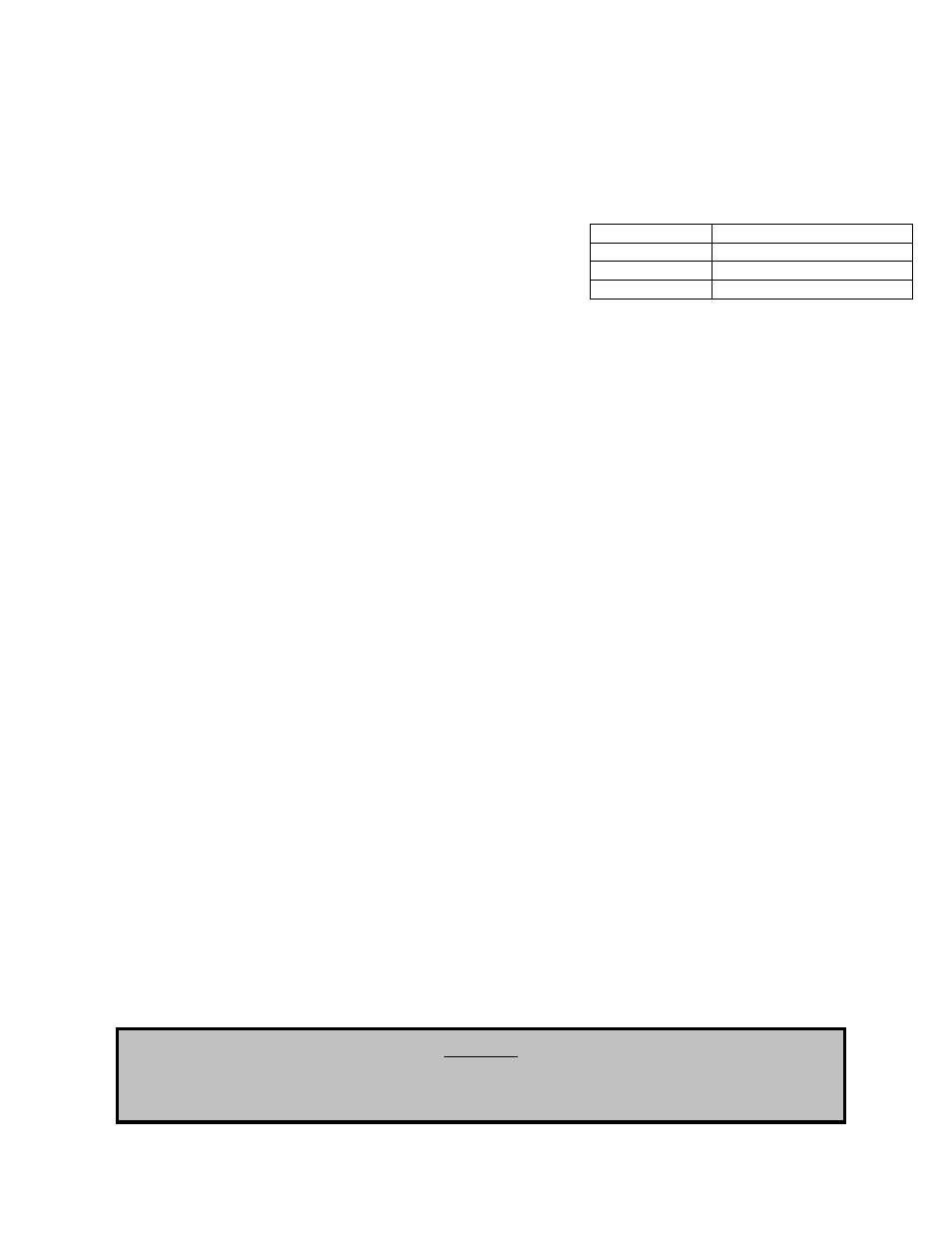

System Nomenclature

System

Water Connection

W1

1 Hot Water

W2

1 Cold Water

W3

1 Hot, 1 Cold Water

INSTALLATION

It is imperative that this unit is installed and operated with the designed airflow and electrical supply in

accordance with this manual. If there are any questions about any items, please call the service

department at 1-866-784-6900 for warranty and technical support issues.

Mechanical

WARNING: APPLY THE APPROPRIATE WATER PRESSURE

AND TEMPERATURE TO ALL FITTINGS TO PREVENT

LEAKAGE AND COMPONENT FAILURE

ATTENTION: SYSTEM MUST BE INSTALLED IN CONDITIONED SPACE BETWEEN 32°F AND 130°F

Ensure there is 36 Inches of service clearance to the front of the panel.

Plumbing Connections for Self Cleaning

Several field plumbing connections are required for proper Self Cleaning hood operation. It is

recommended that all plumbing connections be sealed with Teflon tape or pipe thread sealant. Use care

not to contaminate the interior surfaces of the water lines when plumbing the unit, as small particulate can

clog the orifices of the spray nozzles.

1.

All incoming plumbing connections are connected via ¾” quickseals at the top of the utility

cabinet. See Figures 1 and 2 for details.

2. Self Cleaning hoods with the W1 option (Hot Water Wash) require a hot water connection at

140°F to 170°F and a minimum required PSI, per Table 1, to 50 psi operating pressure. If the

operating pressure is greater than 50 psi, a water regulator must be connected. Max water static

pressure is 125 psi. Typical water flow rate is 0.7 GPM per foot of hood. The spray lasts for a

factory setting of 3 minutes every time the fans are switched off.

3. Self Cleaning hoods with the W2 option (Constant Cold Water) require an unheated water

connection at an operating pressure of 10 to 20 psi. If the pressure is greater than 40 psi, a water

regulator must be connected. Max water static pressure is 125 psi. Typical water flow rate is 0.4

GPM per foot of hood. The spray runs constantly while the fans are turned on.

4. Self Cleaning hoods with the W3 option (Hot Water Wash and Constant Cold Water) require a hot

water connection at 140°F to 170°F and a minimum required PSI, per Table 1, to 50 psi operating

pressure and an unheated water connection at 10 to 20 psi operating pressure. If the pressure is

greater than the max rating, a water regulator must be connected. Max water static pressure is

125 psi. Typical water flow rate is 0.4 GPM per foot of hood for cold water and 0.7 GPM per foot

of hood for hot water. The cold spray runs constantly while the fans are turned on and the hot

water lasts for a factory setting of 3 minutes every time the fans are switched off.

5. If multiple hoods are arranged in an end-to-end or back-to-back arrangement, plumbing

connecting the hoods must be piped in the field. The plugged end of the spray bar is used to do

this. Remove the plugs on the main hood and the adjacent hood and simply pipe the two

together.

6. There is also a non-pressurized 1-1/2 inch drain connection that must be piped. This allows

water to drain from the hood grease trough. It must be connected to the building grease trap.

Hoods 10’ in length (or greater) will require 2 drains. 24” tall hoods with 20” filters will require 2

drains. All other hoods will require 1 drain. See Figure 3 for details.

7. Once all supply and drain lines are connected, remove one of the nozzles and flush the lines.

8. The Ansul fire system duct detection bracket and fusible link are shipped loose to be installed in

the exhaust ductwork. The detector must be installed no more than 20 feet from the hood, and

installed per the Ansul fire system guidelines.

Warning

All field connections between hoods and drain lines must be run with Steel, Stainless Steel, or

Copper pipe. Plastic pipe cannot be used for drains or field connections between hoods, as it

could fail and become hazardous.