Pg 16, Warning – Craftsman 4-Cycle PROPANE POWERED TRIMMER 104.79211 User Manual

Page 16

16

MAINTENANCE

ROCKER ARM CLEARANCE ADJUSTMENT

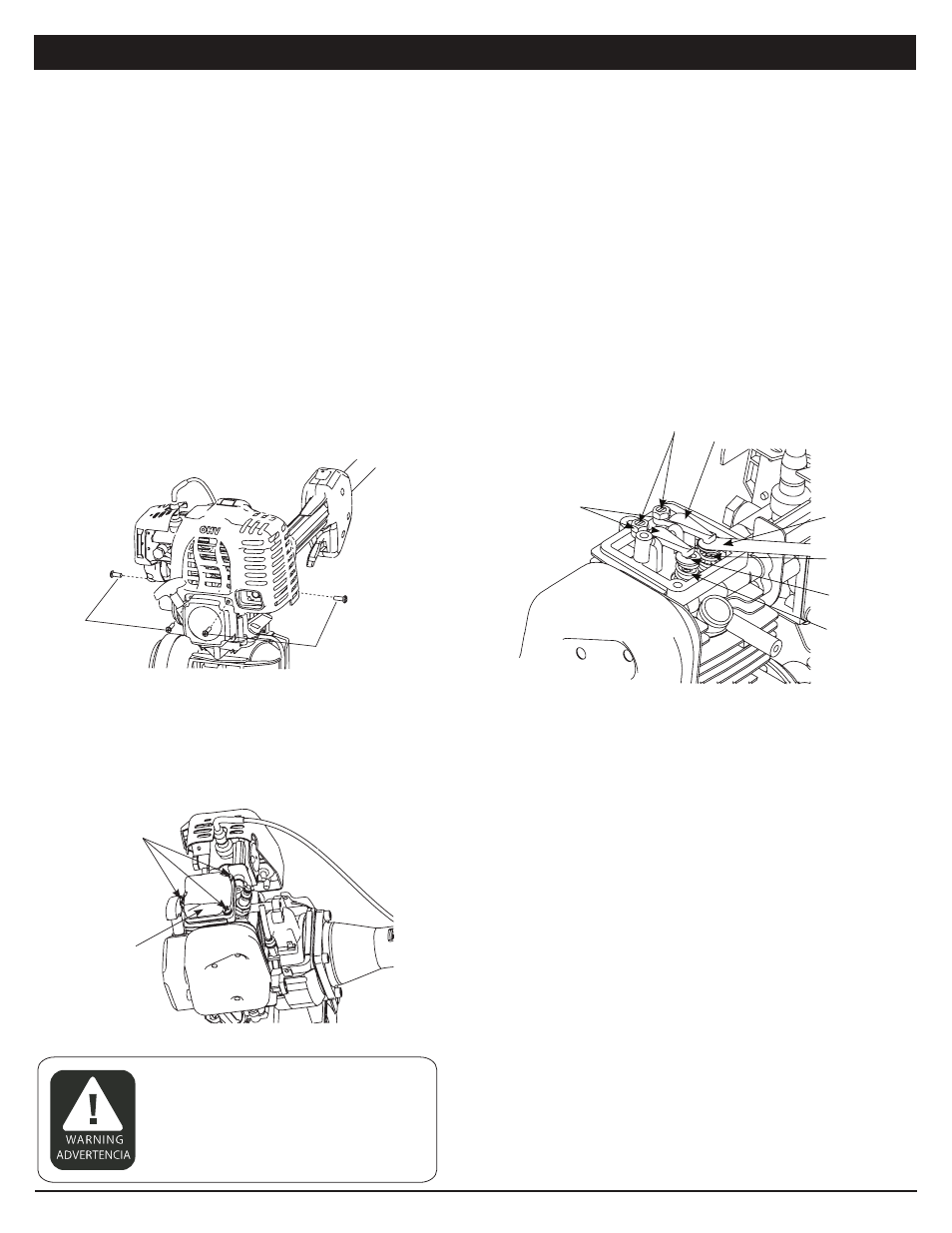

1. Remove the four screws on the engine cover with a

phillips head screw driver (Fig. 26).

2. Remove the engine cover.

3. Disconnect the spark plug wire.

4. Clean dirt from around the spark plug. Remove the

spark plug by using tool provided, turn counterclock-

wise. This requires partial dissasembly of the engine.

If you feel unsure or unqualified to perform this,

take the unit to a Sears or other qualified service dealer.

NOTE: Inspect the valve to rocker arm clearance with a

feeler gage after the first 25 hours of operation. The

engine must be cold when checking or adjusting the

valve clearances. This task should be performed in a

clean dust free environment.

Fig. 26

Engine cover

screws

Engine cover

screws

Fig. 27

Rocker Arm

Cover

Rocker Arm Cover

Screws

5. Clean dirt from around the rocker arm cover.

6. Remove the three screws holding the rocker arm

cover with a phillips head screwdriver.

7. Remove the rocker arm cover and gasket (Fig. 27).

8. Pull the starter rope slowly to bring the piston to

the top of its travel, (this position is known as top

dead center).Check that the piston is at the top of

its travel by looking down into the spark plug hole.

Both valves should be closed and the rocker arms

should move freely. If this statement is not true,

repeat this step until top dead center is acheived

before proceeding to the next step.

9. Slide a feeler gage between the rocker arm and the

valve return spring. Measure the distance between

the rocker arm and valve stem (Fig. 28) Take care

to only measure the free play. It is very easy to

insert too thick a feeler gauge and accidentally

depress the valve and valve return spring. Measure

both the intake and exhaust valve distances.

10. Check the spark plug and reinstall, see Replacing

the Spark Plug (p.14).

11. Reinstall the spark plug wire.

Jam Nuts

Adjusting Screws

Rocker Arm

Feeler Gauge

Exhaust Valve

Intake Valve

Fig. 28

Valve Return

Spring

IF THE CLEARANCE IS NOT WITHIN SPECIFICATION

1. Loosen the jam nut and turn the adjusting screw

as necessary. To increase the clearance, turn the

adjusting screw counterclockwise. To decrease

the clearance, turn the adjusting screw clockwise.

2. Tighten the jam nut when the clearance is set.

3. Recheck the both clearances. Readjust if necessary.

4. Reinstall the rocker arm cover using a new gasket.

5. Tighten cover screws evenly until snug.

6. Reinstall the engine cover checking the alignment of

the cover. Tighten the four engine cover screws until

snug.

• The recommended clearance for both intake and

exhaust is 0.076-0.152mm (0.003-0.006in).

• Use a standard automotive 0.127mm (0.005in) feeler gage.

WARNING:

To prevent serious injury, never perform maintenance

or repairs with unit running. Always service and repair

a cool unit. Disconnect the spark plug wire to ensure

that the unit cannot start.