Vi. set-up – Kistler-Morse KM Load Stand II User Manual

Page 21

17

www.kistlermorse.com

97-1100-01 Rev. H

vI. SET-uP

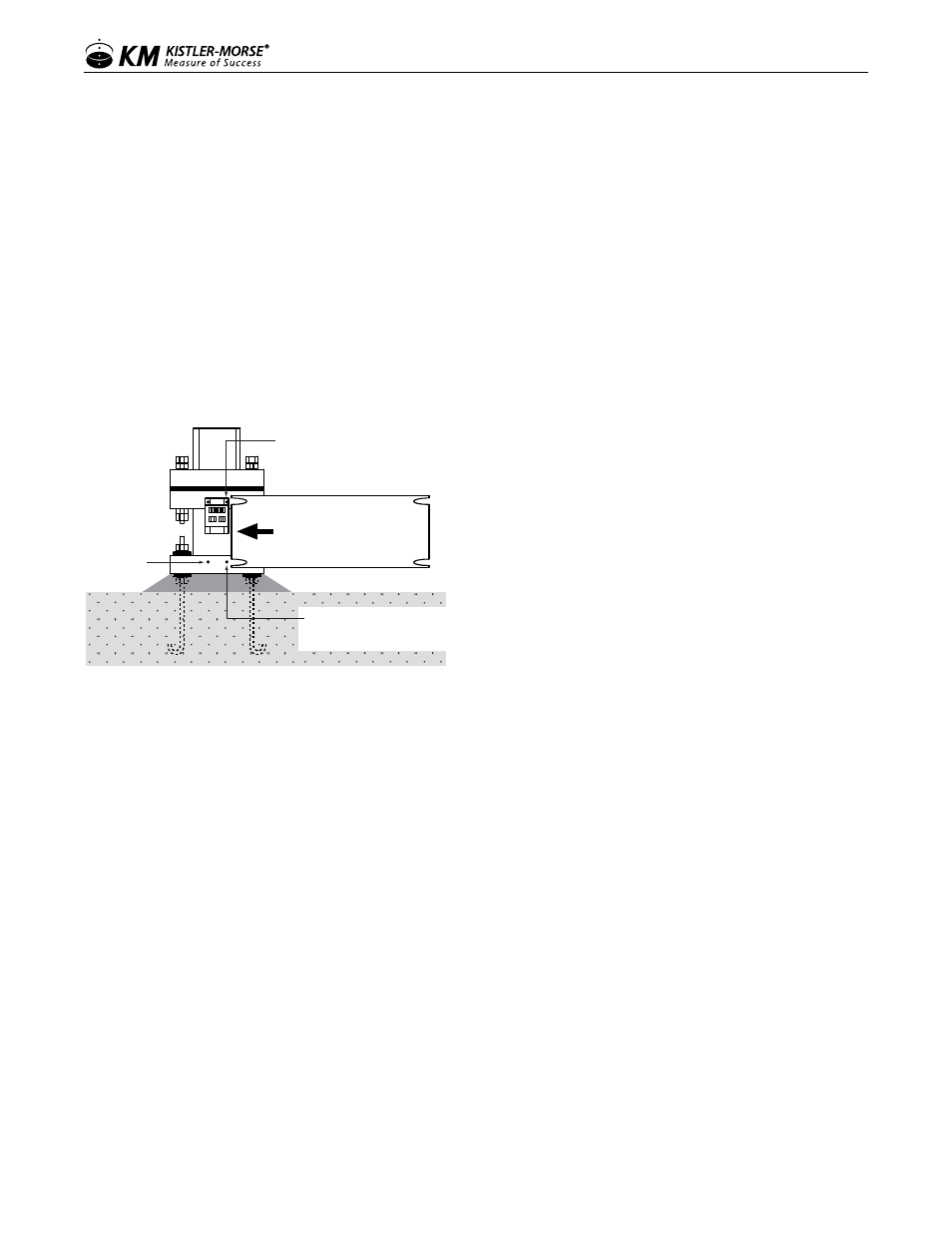

inStaLLinG a Sun ShieLD

The sun shield reduces sun-induced stresses in the Load Stand sensors and provides additional protection for

the sensors.

1. With the junction box cover off, slightly loosen the screws attaching the junction box to the Load Stand.

2. Slightly loosen the horizontal screw(s) on the bottom flange of the Load Stand.

3. Wrap the sun shield around the Load Stand, slipping the cutout slots behind the loosened screws.

4. Tighten the junction box screws and the horizontal screw(s) on the bottom flange.

5. Replace the junction box cover.

Screw not

on all models

Slide sun shield behind junction

box and loosened screws.

Wrap sun shield around

Load Stand. Slide shield behind

junction box and loosened screws

on other end.

Loosen Junction Box screws;

Re-tighten after Sun Shield

is installed.

Loosen Bottom Flange Screw(s);

Re-tighten after Sun Shield

is installed.

caLiBration

There are two calibration methods:

• Live Load calibration — set low span and high span while moving material into or out of the vessel. This is

the preferred method.

• Manual calibration — set scale factor counts, scale factor weight, and zero calibration value without

moving material.

Live Load calibration requires you to move a known quantity of material into or out of the vessel while performing

the procedure. The quantity of material moved must be at least 25% of the vessel’s total capacity to provide best

accuracy. Live Load calibration is also based on the material weight currently in the vessel. Manual calibration

allows you to start using the system as soon as Load Stands and signal processor are installed and wired, even

if you cannot move any (or enough) material now. Manual calibration values are based on system parameters,

including sensor sensitivity, rated load, and signal processor A/D converter sensitivity. These values are known,

can be calculated, or can be obtained from the signal processor. Manual calibration is also based on the material

weight currently in the vessel.

Note that manual calibration does not take into account the actual response to changes in weight. Theoretically,

a change in weight results in a proportional change in digital counts. However, the structure’s actual response

to weight and interaction with piping catwalks, roof, discharge chutes, etc. prevents the system from achieving

theoretical values. Manual calibration is a good start, but to obtain the highest accuracy, perform a Live Load