Losi LOSB0210 User Manual

Page 4

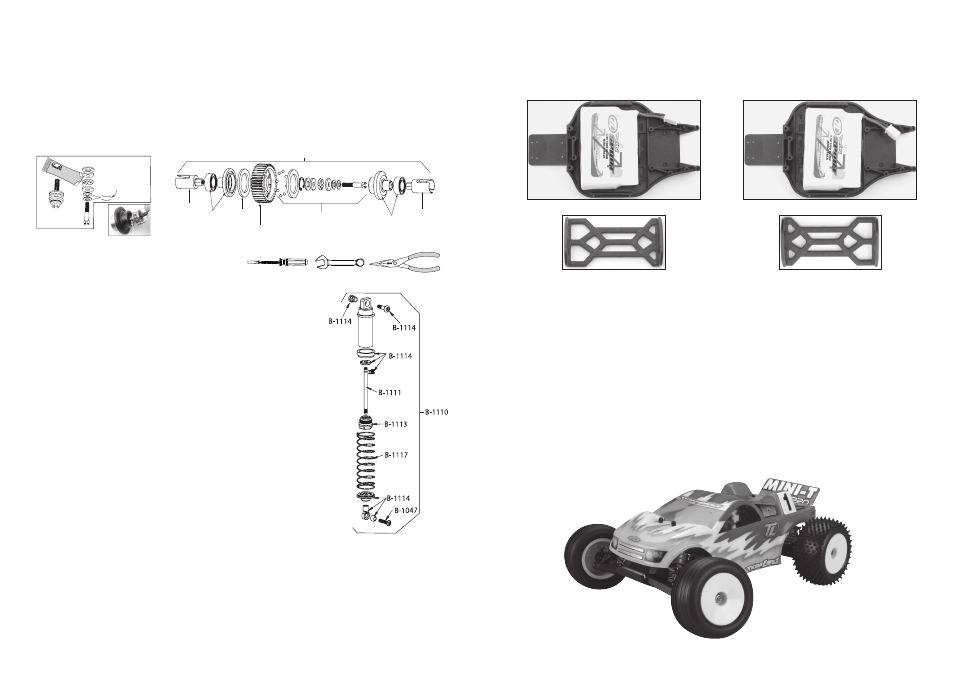

Rebuilding The Ball Differential

1) Remove your ball differential from your tranny. 2) Remove left outdrive cup and loosen diff ad-

justing screw with a small flathead screw driver or a .050 allen wrench. Remove right side outdrive

assembly.

3) Clean diff gear, diff rings and balls. If needed, replace worn parts and lube with Losi

Silicone Diff Grease LOSA3065

4) Remove “C” clip from male oudrive half and carefully remove

diff thrust assembly.

5) Clean all thrust components and replace if needed. Reassemble thrust

components

(Figure5). 6) Install thrust assembly into male oudrive as shown in (Figure 6). Install

a new “C” Clip.

7) While holding male outdrive half install large diff washers, diff gear with balls. 8)

Apply thread lock to diff screw and reassemble diff. Carefully bottom the diff screw out and back

the screw out 1/16th of a turn. Your diff is now set.

9) Reassemble tranny. 10) Refer to Ball Diff/

Slipper Adjustment Instructions on the previous page.

SYNTH

ETIC

LUBRIC

ANT

LOSA

306

6

Fig 5.

Washers should

be stacked in

this order

Screwhead

Fig 6.

LOSB1129

LOSB1128

LOSB1125

LOSB1126

LOSB1127

LOSB1126

LOSB1128

LOSB1129

Body Painting

Before you start, please note the following tips. Use only paint that is designed for polycarbonate

bodies or it may chip, flake, or cause the body to crack. Use quality masking tape (3M, Scotch,

etc) or commercially available precut masks (XXX Main, Parma, etc) – do not use clear “sealing”

tape, as it is very difficult to remove. Always try to apply darker colors first. Backing a lighter color

with white will produce a brighter appearance. Back white with a coat of silver (unless it is the last

color applied) to prevent other colors from bleeding through. Always allow plenty of time for the

paint to dry before pulling the tape or applying another color.

1) Wash the inside of the body with a little liquid detergent and warm water. 2) After drying thor-

oughly, position the precut window masks (supplied) to the inside of the body and firmly press

them down for good adhesion.

3) Use masking tape or precut masks (not supplied) to the inside of

the body to produce the pattern you desire. Try to tape the body so you will apply the darker colors

first following the tips noted above.

4) Follow the paint manufactures instructions when applying

the paint being careful not to allow it build up in any one spot. Remember to allow plenty of dry-

ing time between colors.

5) Remove the window masks and protective film from the outside of the

body. Use R/C Body cleaner or Isopropyl Alcohol (do not use any hot solvents) to clean up any

overspray etc. on the outside of the body if any, before applying the stickers.

Battery Placement

The Mini T Pro features a choice of battery positions. In the “Back” position, the Mini-T Pro will

have a bit more traction and will jump nose high with less steering. In the “Forward” position, the

Mini-T Pro will have more steering and jump with the nose down. Try playing with the different

positions to find the best handling for your track.

Battery Position “Back”

Battery Position “Forward”

Filling and Maintaining the Racing Shock Absorbers

Filling and Bleeding Your Shocks

1. Remove the spring by pushing the lower

spring cup away from the shock end and sliding

it out, off of the shaft.

2. Unscrew the shock cartridge (7mm) and remove the shaft/cartridge/

piston assembly.

3. Use the included Team Losi 20 weight silicone fluid to fill the shock

body to the bottom of the internal threads.

4. With the shaft half way through the cartridge, insert the piston into the

fluid and start to thread the cartridge into the body approximately two turns.

5. With the cartridge loose, and holding the shock with the shaft up, push

the shaft all the way in, allowing the excess fluid to escape.

6. Tighten the cartridge down (about 1/2 to 1 turn) being careful not to

stripe the threads.

7. Move the shaft back and forth through its normal range of movement.

There should be a costant resitance. If there is a greater resistance as the

shaft is fully compressed, there is too much oil and it needs to be re-bled

by following step #5. If there is less resistance at any point, there is not

enough oil and you need to repeat steps #2 through #5. Otherwise, re-

place the spring and spring cup.

NOTE: If leakage occurs where the cartridge seals to the shock body, you

should replace the thin circular seal between the shock cartridge and shock

body.

Helpful Tools

Small Screwdirver 7mm Wrench

Pliers

Changing the Shock Cartridge

1. Remove the cartridge/assembly from the shock.

2. Remove the shock piston and the small e-clips above and below it.

3. Remove the old cartridge an dslide the new cartridge onto the shaft. Replace the e-clips and

shock piston. Put a new seal onto the cartridge and follow steps #3 through #6 above.

Changing the Pistons

1. Remove the cartridge/assembly from the shock.

2. Remove the e-clip from above the piston at the end of the shock shaft.

3. Replace the piston wit the one of you choice (small, medium or large hole.

4. Replace the e-clip and follow steps #3 through #6 above.

NOTE: Always replace front or rear pistons in pairs-never just one piston.