Losi LOSB0210 User Manual

Page 3

Making Adjustments

The following are simple adjustments and easily maintained settings that will assure proper opera-

tion and performance. Since the Mini-T Pro comes from the factory with optimum settings, we sug-

gest first-time R/C drivers leave these as they are and simply maintain them as necessary. Only

after gaining experience should new drivers try experimenting with different settings.

Chassis Tuning

The Mini-T Pro has several adjustments available to you for tuning the performance for your

needs. Although there are multiple shock positions and camber link locations provided, as noted

above we have built the model with the best overall settings. The following are simple adjustments

and easily maintained settings that will assure proper operation and performance. It is advised that

when making any adjustment you do so in small increments and always check for other parts of

the chassis that are affected.

Steering Rate

Your transmitter may be equipped with a steering rate control. This

feature allows you to adjust the amount the front tires move when you

turn the steering wheel. This is really helpful when you are on slick as

well as high traction surfaces. If your Mini-T Pro turns too sharply

and/or spins out easily, try decreasing the steering rate. For sharper

or additional steering, try increasing the steering rate.

“Less Rate”

“Full Rate”

Camber

Camber is the angle of the tires to the racing surface when viewed

from the front or rear of the truck. You want to keep both the front

and rear tires straight up and down or leaning in at the top very

slightly. If you are running on carpet or similar high traction sur-

faces you may find leaning them in a bit more helps. This adjust-

ment is made with the turnbuckle links that extend from the front

or rear bulkhead to the spindle carrier or rear hub. The Mini-T Pro

is equipped with adjustable Titanium Turnbuckles that if turned

one way (using the provided wrench) get shorter and if turned in

the opposite direction get longer. Making these shorter increases the camber and lean-in of the tire

while making them longer decreases the camber.

No Camber

More Camber

Toe-In

This is the relationship of the left and right side tires to one

another. Ideally, you want the front of the tires to be pointed

inward toward each other just slightly when viewed from

above. This makes the model track straight and stable. This

is controlled with the adjustable steering rods on either side.

As you make them longer you will increase the toe-in and

vice versa.

No Toe-In

More Toe-In

Ride Height

This is the height the chassis sits and runs at. There are spring spacers included with the Mini-T

Pro that, when installed between the shock top and spring, will increase the pre-load on the spring

and raise the chassis. You may want to try this when running on extremely rough surfaces.

More Pre-load

Less Pre-load

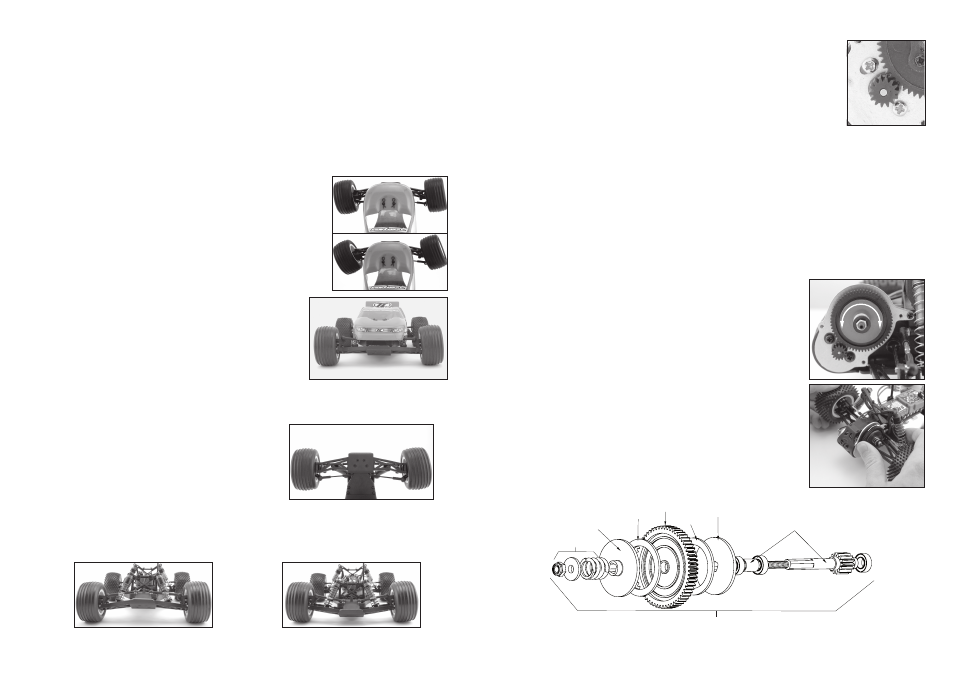

Slipper Adjustments

The Mini-T Pro is equipped with a Double Disk slipper device that

offers both traction control and protection for the transmission. The

slipper is primarily used to help absorb sudden impacts on the drive

train due to landing big jumps or when using more powerful aftermar-

ket motors and/or battery packs. Additionally, it can be used to smooth

out the flow of power to the rear wheels and limit wheel spin when

running on extremely slick surfaces. Adjustment is made by removing

the access plug in the gear cover and turning the 3mm adjustment

nut clockwise (to the right) to reduce the slip or counterclockwise (to

the left) to increase the slip

(Figure 3). When adjusted properly, you

should be able to hold the rear tires firmly and barely be able to push

the spur gear forward with your thumb

(Figure 4). To track test, turn

the Mini-T on and place it on the ground. As you push it backwards

allowing it to roll freely, punch the throttle. The slipper should slip no

more than an inch or two as it accelerates. With a 5 or 6 cell battery

pack it should slip just a little. Make sure you replace the gear cover

before running.

Increase

Slip

Reduce

Slip

Figure 3

Figure 4

Ball Diff/Slipper Adjustment Instructions

Always make sure your slipper will slip before the diff, as this will diminish the load on the dif-

ferential and transmission. The diff should never slip. Hold the right tire and the spur gear in one

hand and rotate the left tire. As you rotate the left tire, the slipper plate, and shaft should turn. This

means the slipper is slipping before the differential. If the slipper shaft is not turning, your differen-

tial is slipping. You must either tighten the diff and/or loosen the slipper and recheck. To tighten the

diff, remove the left side driveshaft and use a .050” Allen wrench and turn the diff screw clockwise

in one-hour increments and recheck as noted above until it no longer slips. Any time you tighten

the slipper you should check the diff as noted and tighten if necessary.

NEVER Let your differential slip!

Follow the instructions below for proper operation and adjustment

LOSB1133

LOSB1134

LOSB1135

LOSB1137

LOSB1135

LOSB1134

LOSB1132

*Gear Cover LOSB1136

LOSB1131 (Bearings not included)

Setting The Gear Mesh

The motor screws should be slightly loose. Slide the motor forward allowing the

pinion gear to mesh with the spur gear. Snug (not tight) the bottom motor screw

and try rocking the spur back and forth. There is a slight bit of movement before

the motor is forced to turn over. If not, pull the top of the motor back slightly and

recheck, there should be a slight bit of movement. If there is too much slop

between the gears push the top of the motor forward. When set properly the

wheels can be spun forward freely with very little noise. Make sure to tighten

both motor screws and replace the gear cover before running.