Cleaning steering gears, Cleaning the tractor and deck, Using deck wash system – Craftsman 247.28933 User Manual

Page 118: Battery, Service and maintenance, Tires, Warning

Attention! The text in this document has been recognized automatically. To view the original document, you can use the "Original mode".

SERVICE AND MAINTENANCE

TIRES

A

warning

Never exceed the maximum inflation pressure shown on the sidewall

of tire. Refer to the tire sidewall for exact tire manufacturer’s recom

mended or maximum psi. Do not overinflate.

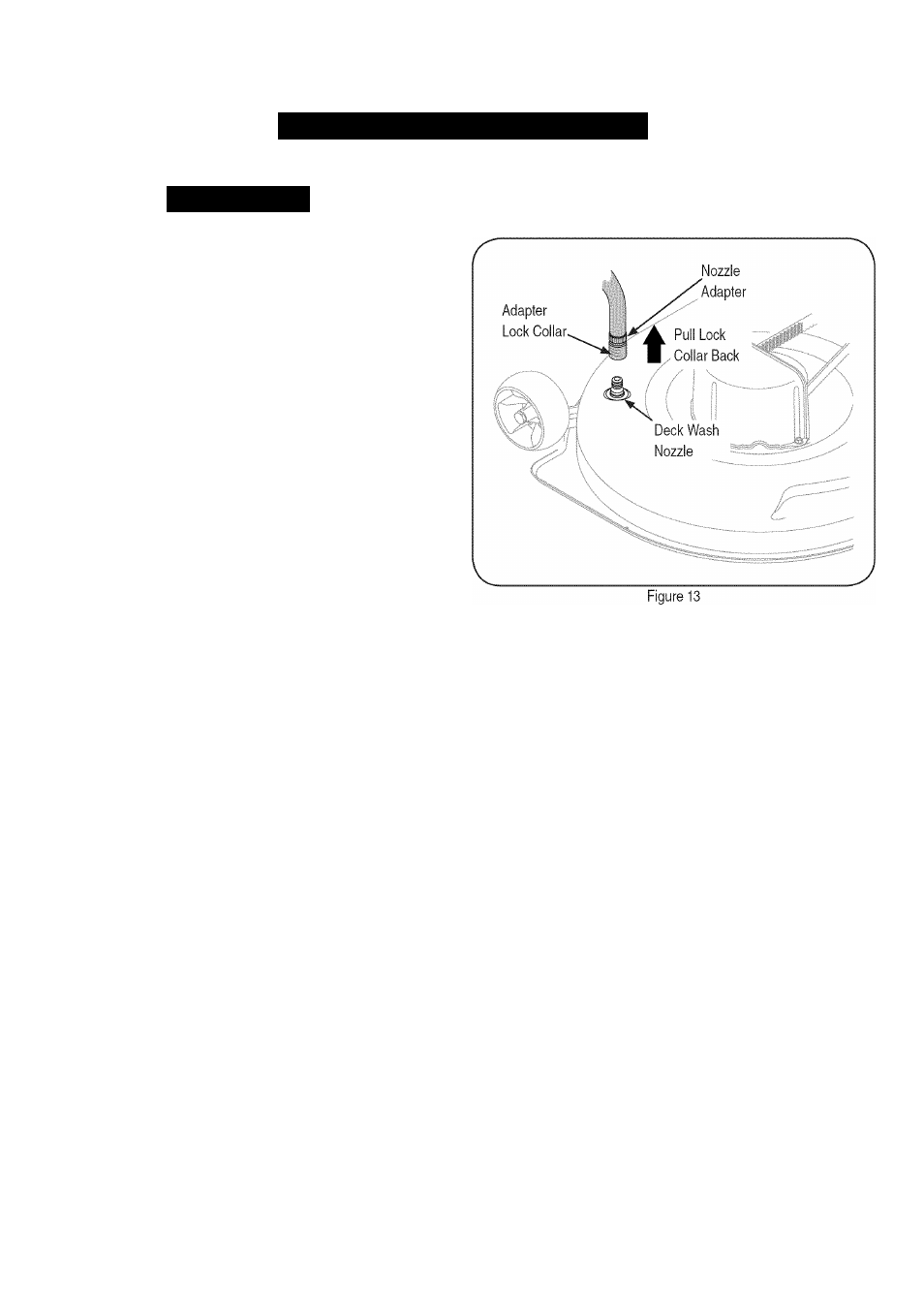

4. Pull back the lock collar of the nozzle adapter and push the

adapter onto the deck wash nozzle at the left end of the mower

deck. Release the lock collar to lock the adapter on the nozzle.

See Figure 13.

The recommended operating tire pressure is:

•

Approximately 10 psi for the rear tires

•

Approximately 14 psi for the front tires

IMPORTANT: Uneven tire pressure could cause the cutting deck to

mow unevenly.

CLEANING STEERING GEARS

Once a year, or it a tight spot is experienced when turning the steering

wheel, remove the steering gear cover on each end of the pivot bar

and clean the two steering gears.

1.

From beneath the cover base plate on each end of the pivot bar,

remove the three hex screws securing the steering gear cover.

Remove the covers and clean the gears. It is not necessary to

lubricate the gears. Refer to Figure 12.

2.

Insert the tab of the LH steering gear cover into the square hole

in the LH base plate, position the cover, and secure with the three

hex screws. Do not over tighten. Repeat to install the cover on the

RH side.

CLEANING THE TRACTOR AND DECK

Any fuel or oil spilled on the machine should be wiped off promptly. Do

NOT allow debris to accumulate around the deck pulleys or any other

part of the machine.

Periodically remove the belt covers and remove any accumulated

grass clippings from around the spindle pulleys and the deck belt.

IMPORTANT: The use of a pressure washer to clean your tractor is

NOT recommended. It may cause damage to electrical components,

spindles, pulleys, bearings or the engine.

Using Deck Wash System^“

Use the Deck Wash System™ to rinse grass clippings from the deck's

underside and prevent the buildup of corrosive chemicals. Your trac

tor's deck is equipped with a water nozzle on the left end of the deck.

Complete the following steps AFTER EACH MOWING:

1.

Drive the tractor to a level, clear spot on your lawn, near enough

to a water sillcock (spigot) for your garden hose to reach.

IMPORTANT: Make certain the tractor’s discharge chute is directed

AWAY from your house, garage, parked cars, etc.

2.

Disengage the PTO (Blade Engage), set the parking brake, and

stop the engine.

3.

Thread the nozzle adapter (packaged with your tractor's Opera

tor's Manual) onto the end of your garden hose.

5.

Turn the water on.

6

.

While sitting in the operator's position on the tractor, re-start the

engine and place the throttle lever in the FAST (rabbit) position.

7.

Move the tractor's PTO (Blade Engage) into the ON position.

Remain in the operator's position with the cutting deck engaged

fora minimum of two minutes, allowing the underside of the

cutting deck to thoroughly rinse.

8

.

Move the tractor's PTO (Blade Engage) into the OFF position.

Turn the ignition key to the STOP position to turn the tractor's

engine off.

9.

Pull back the lock collar of the nozzle adapter to disconnect the

adapter from the nozzle.

BATTERY

The battery is sealed and is maintenance-free. Acid levels cannot be

checked.

•

Always keep the battery cables and terminals clean and free of

corrosive build-up.

•

After cleaning the battery and terminals, apply a light coat of

petroleum jelly or grease to both terminals.

•

Always keep the rubber boot positioned over the positive terminal

to prevent shorting.

IMPORTANT: If removing the battery for any reason, disconnect

the NEGATIVE (Black) wire from its terminal first, followed by the

POSITIVE (Red) wire. When re-installing the battery, always connect

the POSITIVE (Red) wire its terminal first, followed by the NEGATIVE

(Black) wire. Be certain that the wires are connected to the correct

terminals; reversing them could change the polarity and result in

damage to your engine’s alternating system.

22