Model hc, Model hc clutch description, Operational data – Wichita Clutch HC HCD Clutch User Manual

Page 3

Model HC

MODEL HC CLUTCH DESCRIPTION

The Model HC clutches are designed to be used in either an

end of shaft or through shaft mounting configuration. Their

compact size makes these units ideal for incorporating

within a gear housing. Multiple speed transmissions use a

variety of these units to effect fixed mesh speed changes or

they may be used as a stand alone device for disconnect

service.

The Model clutches may be provided with an internally

splined outer drive ring for bolting to the user’s driving or

driven member, or Model HC clutches may be provided

without this drive ring to allow the user to spline the inside

diameter of their driving or driven member which conserves

radial space and provides for design compactness.

All units incorporate provisions for forced oil cooling allowing

high energy engagements to be made without causing

thermal distress within the disc pack. Cooling oil is

introduced from an external supply through axial holes

provided in the shaft.

Actuation pressure may come from either a pneumatic or

hydraulic source. This pressure may be introduced through

an axial hole provided at the shaft centerline, or, in the case

of end of shaft mounts, it may be introduced through a

separate manifold.

All torque transmitting members are designed for continuous

heavy duty industrial service. Hubs and drive rings are fully

hardened and manufactured from high quality alloy steel

forgings. Disc pack cores are designed using extra-heavy

plate thicknesses to maximize torque and heat capacity.

Friction materials and grooving patterns are designed to

provide for high thermal and smooth engagement performance.

All of the Model HC clutches contain friction materials which

allow for controlled slip operation in those applications

requiring this feature. Slip operation is described on

following pages.

Marine main propulsion forward/reverse or disconnect service,

winch disconnects, conveyor or mill soft-starts, and

multi-speed transmissions are but a few of the applications

for the Model HC oil immersed clutches.

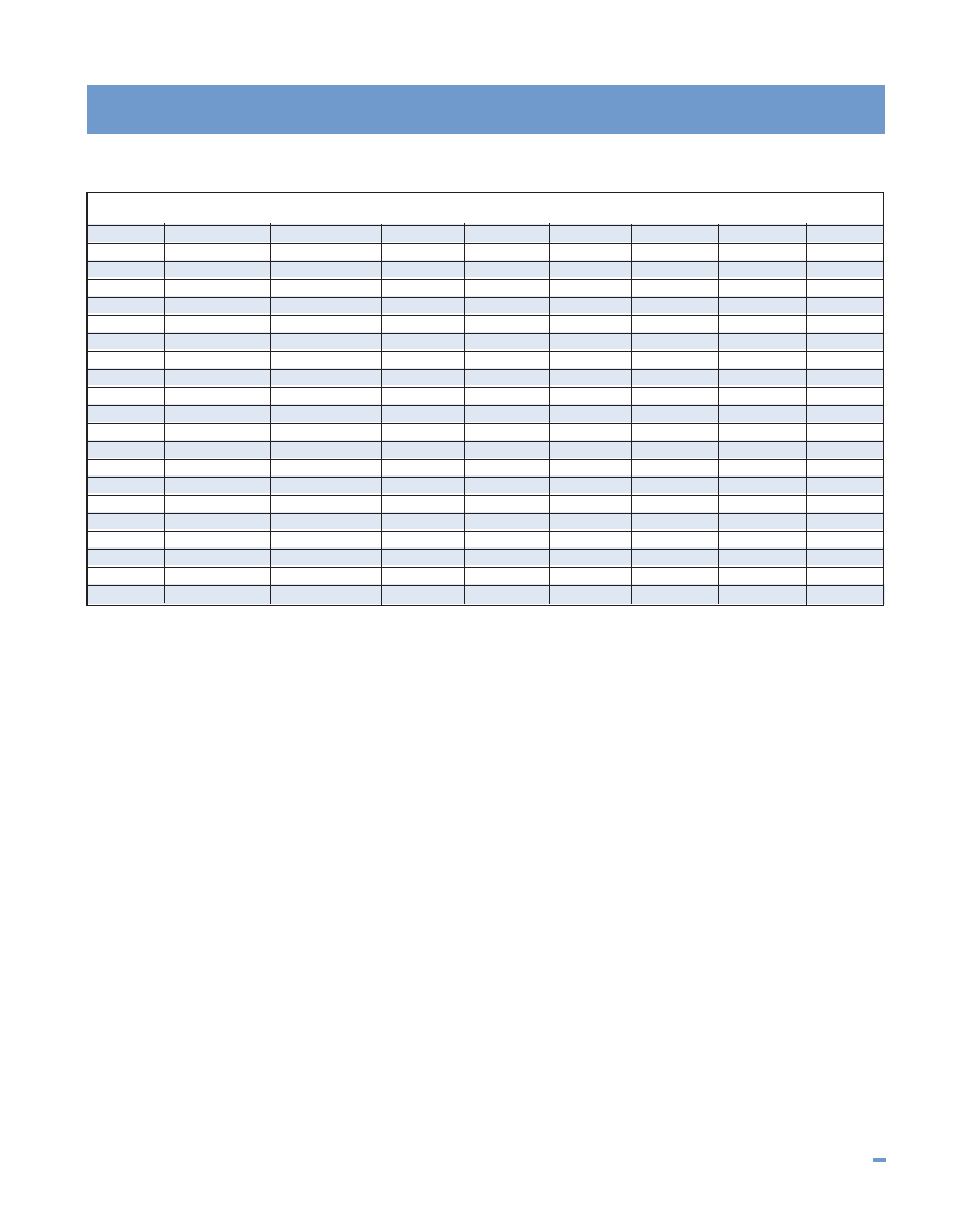

NOTES: 1.) Operating pressure: 350 PSIG

2.) Torque capacities can be modified. Consult engineering.

3.) Consult factory for service factors required per application.

4.) Consult factory for oil flow requirements per application and shaft oil hole diameters.

5.) For static engagement applications dry lining units are available. Torque ratings are 3 times that shown. Consult Engineering

Clutch

Static

Dynamic

Act. Vol.

Weight

Weight

WR

2

Outer

WR

2

Inner

Maximum

Model

Torque (lb.-in.)

Torque (lb.-in.)

(in.

3

)

Outer (lbs.)

Inner (lbs.)

(lb.-ft.

2

)

(lb.-ft.

2

)

RPM

HC-8-6

55000

39285

4.37

5.8

60.6

0.54

3.79

2600

HC-8-8

70000

50000

4.37

7.7

65.3

0.72

4.04

2600

HC-8-10

85000

60715

4.37

9.7

70.0

0.90

4.29

2600

HC-10-6

75000

53570

7.3

7.8

83.7

1.03

7.50

2200

HC-10-8

100000

71430

7.3

10.4

90.7

1.38

8.06

2200

HC-10-10

125000

89285

7.3

13.0

97.6

1.72

8.60

2200

HC-13-6

200000

142860

14.0

16.3

195.7

4.3

35.9

1700

HC-13-8

275000

196430

14.0

21.7

212.1

5.8

38.4

1700

HC-13-10

350000

250000

14.0

27.1

227.4

7.2

40.8

1700

HC-15-6

325000

232140

19.0

34.0

291.0

11.0

67.0

1450

HC-15-8

425000

303570

19.0

45.0

316.0

15.0

72.0

1450

HC-15-10

525000

375000

19.0

57.0

341.0

19.0

77.0

1450

HC-16-6

450000

321430

24.0

40.0

357.0

16.0

103.0

1300

HC-16-8

600000

428570

24.0

54.0

387.0

22.0

110.0

1300

HC-16-10

750000

535715

24.0

67.0

417.0

27.0

118.0

1300

HC-18-6

570000

407140

31.0

63.0

494.0

30.0

164.0

1200

HC-18-8

700000

500000

31.0

84.0

544.0

40.0

179.0

1200

HC-18-10

950000

678570

31.0

105.0

594.0

50.0

194.0

1200

HC-20-6

765000

546430

51.0

95.0

671.0

58.0

279.0

1100

HC-20-8

1020000

728570

51.0

127.0

729.0

78.0

300.0

1100

HC-20-10

1275000

910710

51.0

158.0

786.0

97.0

321.0

1100

OPERATIONAL DATA

I N D U S T R I A L C L U T C H P R O D U C T S

80