Straight pattern, Materials of construction, Pressure – temperature dimensions—weights – Watts CSM-91 User Manual

Page 2: Installations, Flange adapter details, Elastomers, Ductile iron flange adapters for ansi 150# flanges, Grooved end with 375psi rated pipe coupling

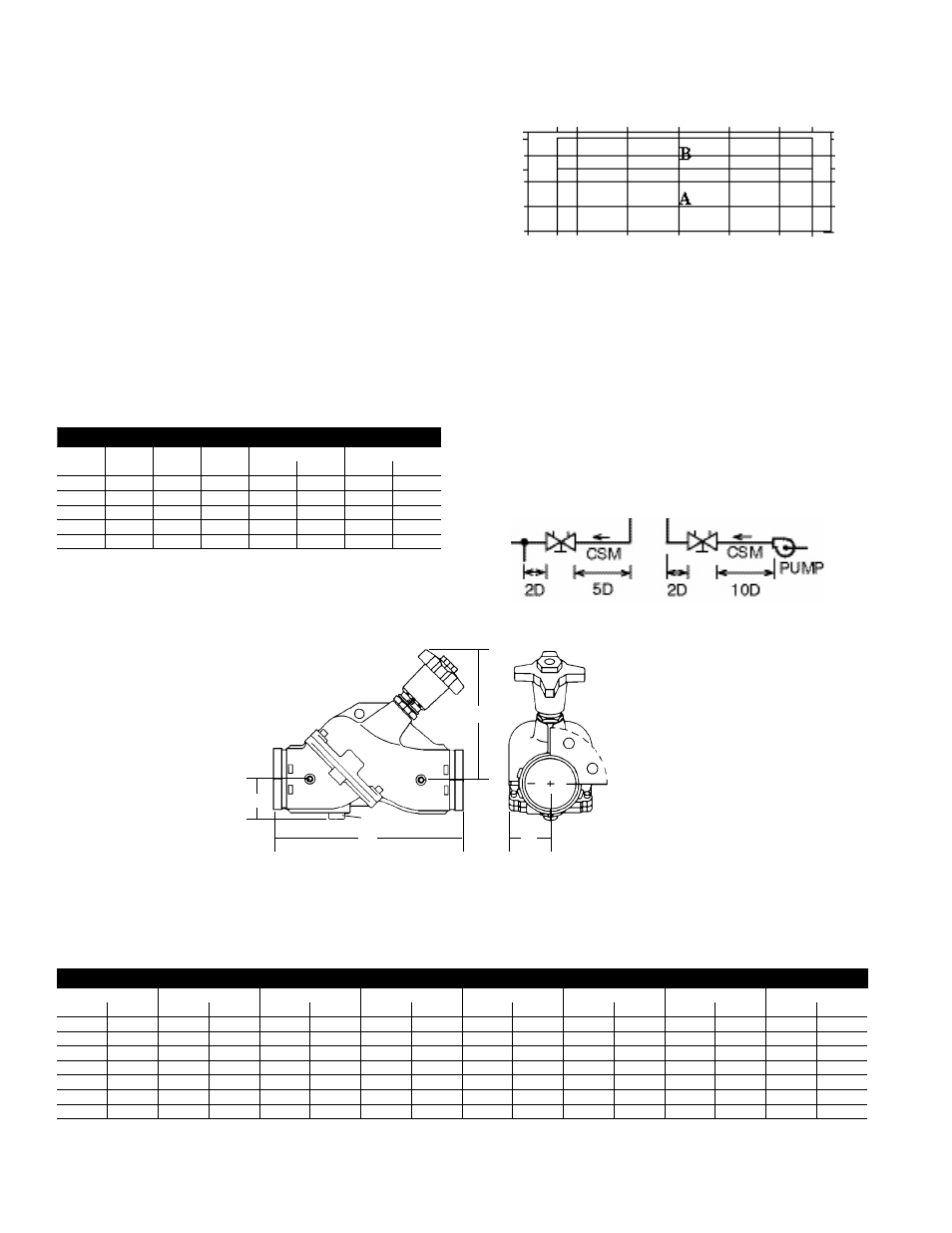

Straight Pattern (Stan dard)

Straight Pattern

Size (DN)

DiMeNSioNS

FlaNge Dia. 125#

SpaCer

Weight

A

C

D

F

in.

mm

in.

mm

in.

mm

in.

mm

in.

mm

in.

mm

in.

mm

lbs

kgs

2

1

⁄

2

65

12

305

9

5

⁄

8

245

2

3

⁄

4

70

2

9

⁄

16

65

7

178

1

25

19

9

3

80

12

305

10

1

⁄

2

267

2

7

⁄

16

62

3

76

7

1

⁄

2

191

1

25

24

11

4

100

14

356

10

9

⁄

16

268

3

76

3

7

⁄

16

87

9

1

⁄

4

235

1

1

⁄

4

32

42

19

5

125

17

1

⁄

2

445

13

1

⁄

16

332

3

5

⁄

8

92

4

15

⁄

16

125

10

254

1

1

⁄

4

32

81

37

6

150

20

11

⁄

16

525

13

3

⁄

4

349

4

7

⁄

16

113

5

7

⁄

8

149

11

279

2

51

120

54

8

200

28

3

⁄

16

716

24

5

⁄

8

625

5

11

⁄

16

144

7

7

⁄

8

200

13

1

⁄

2

343

2

1

⁄

4

57

310

141

10

250

30

762

26

1

⁄

2

673

6

9

⁄

16

167

9

15

⁄

32

241

16

406

2

1

⁄

4

57

460

209

Materials of Construction

Body

Ductile Iron ASTM A536 GR65-45-12

Disc

Bronze ASTM B584 C-84400

Seat

2

1

⁄

2

" – 6" Engineered Resin

8" – 10" EPDM

Stem

Brass ASTM B-16 2

1

⁄

2

" – 6" (65 – 150mm)

Stainless Steel 8" – 10" (200 – 250mm)

O-ring

Buna-N

Memory Lock

Brass ASTM B-16

Meter Ports

NPT Brass body with Schrader Valve

Drain Tappings (2)

1

⁄

4

" Brass plug

Optional Equipment

Flange Adapters

Ductile iron

Flange Gaskets

EPDM

Insulation Fiberglass

Note: Series CSM-91 valves are shipped with grooved ends stan dard. For com-

pan ion flang es, please specify size and class rat ing when or der ing. In su la tion

blocks are also or dered sep a rate ly from valve. Please spec i fy size when or der ing.

Pressure – Temperature

Dimensions—Weights

Spac er

t

Flange

Dia.

Installations

Generally locate the valve five pipe diameters downstream from a

fitting; with two diameters downstream from the balancing valve

free from fittings. If a balancing valve is located downstream from

a circulation pump, allow a distance of ten (10) diameters between

the pump and balancing valves (as illustrated below).

Flange Adapter Details

ValVe Size

pipe o.D.

125pSi

Bolt

Bolt Circle Diam.

in.

mm

in.

mm

No.

Size

in.

mm

2

1

⁄

2

64

2

7

⁄

8

73

4

5

⁄

8

x 3

5

1

⁄

2

140

3

76

3

1

⁄

2

89

4

5

⁄

8

x 3

6

152

4

102

4

1

⁄

2

114

8

5

⁄

8

x 3

7

1

⁄

2

191

5

127

5

9

⁄

16

140

8

3

⁄

4

x 3

1

⁄

2

8

1

⁄

2

216

6

152

6

5

⁄

8

168

8

3

⁄

4

x 3

1

⁄

2

9

1

⁄

2

214

temperature ˚C

temperature ˚F

Note:

For temperatures between 230˚F and 300˚F

(110˚C and 149˚C), specify Viton

®

Elastomers

pressure psi

pressure k

pa

-46˚ -29˚ -18˚

10˚

38˚

66˚

93˚

110˚

-50˚ -20˚ 0˚

50˚

100˚

150˚

200˚

230˚

400

375

300

250

200

100

0

2760

2585

2070

1724

1380

690

250

legend

A –

Ductile iron flange adapters for ANSI 150# flanges

B –

Grooved end with 375psi rated pipe coupling

2

D

A

C

F