Watts CSM-91 User Manual

Series csm-91, Flow measurement/balancing valves, For balancing and flow measurement applications

For Balancing and Flow Measurement Applications

ES-CSM-91

Series CSM-91

Flow Measurement/Balancing

Valves

Sizes: 2

1

⁄

2

" – 10" (65 – 250mm)

Series CSM-91 Flow Measurement/Balancing Valves are designed

for applications on medium or large flow rate HVAC systems, pump

packages, and cooling towers. They feature a multi-turn adjustment

range for maximum control. Pressure differential readout ports on

both sides of the valve to allow for easier installation and positive

shutoff for servicing equipment. In addition, these valves also incor-

porate a micrometer type handwheel adjustment, visually readable

settings and a tamper-proof memory stop.

The CSM-91’s field-convertible design allows the valve to be

changed from the factory-standard straight pattern to an optional

angle pattern with standard tools and no additional parts. This

allows the valve to be used as a replacement for angles or elbows

and will not affect the valve’s accuracy.

Maximum flow requires a one-foot pressure drop across the valve

to obtain an accurate meter reading with the valve set point from

50% to 100% open for greatest accuracy.

The valve should be installed with flow in the direction of the arrow

on the valve body, and installed at least five pipe diameters down-

stream from any fitting, and at least ten pipe diameters downstream

from any pump. Two pipe diameters downstream from the CSM-91

should be free of any fittings. When installed, easy and unobstructed

access to the valve handwheel and metering ports for adjustment

should be provided. Mounting of the valve in piping must prevent

sediment buildup in metering ports.

Features

• Multi-turn adjustment

• Interchangeable metering and drain ports on both sides

of valve

• Positive shutoff

• Tamper-proof memory stop

• Micrometer type handwheel adjustment - visually readable from

distance

• Field convertible for straight or angle pattern

• Grooved end connections with optional flange adaptors

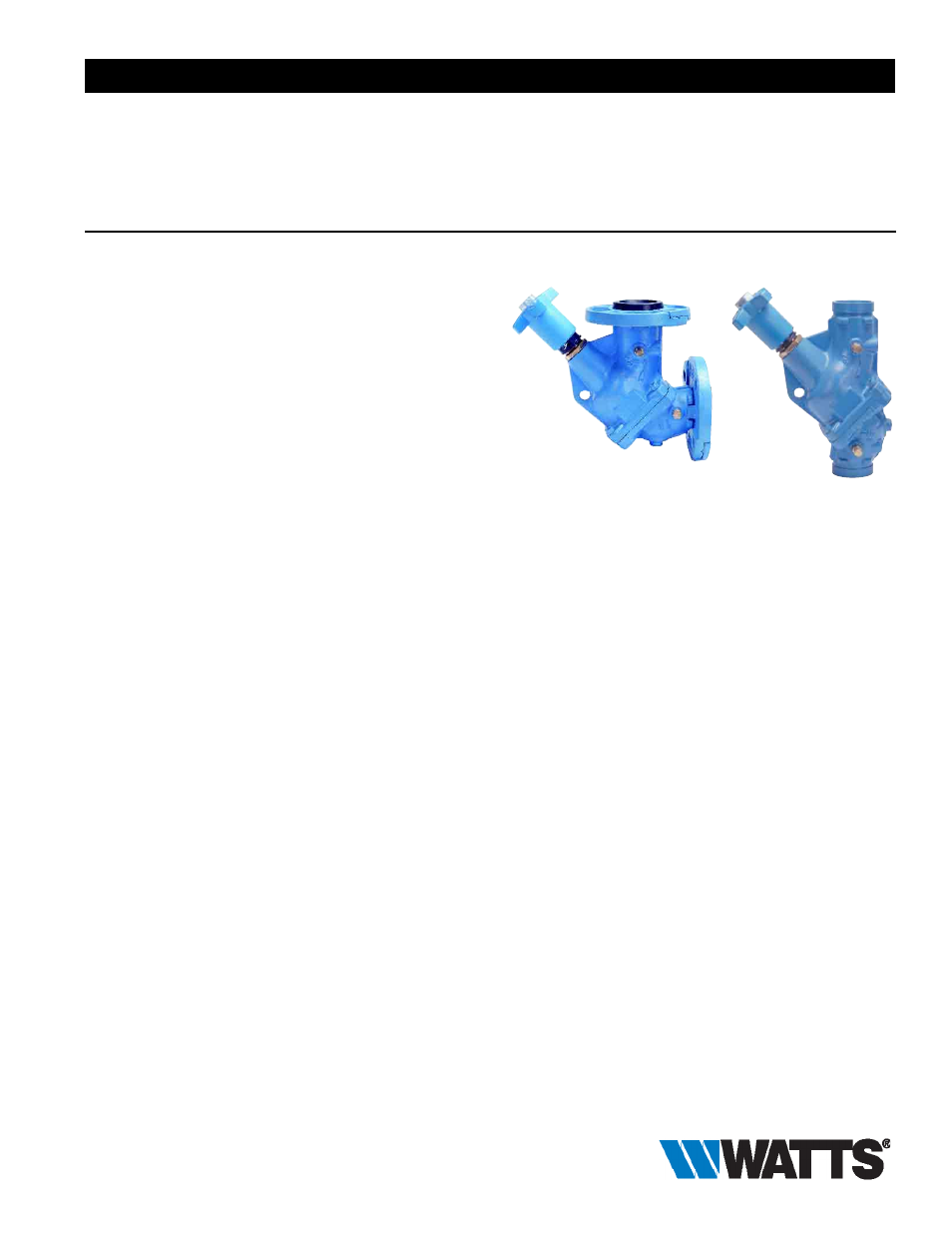

Angle Pattern

Straight Pat tern

Specifications

A flow measurement valve shall be installed as shown on plans.

Each valve shall have two

1

⁄

4

” (6mm) NPT brass metering ports with

Nordel

®

check valves and gasketted caps located on both sides of

valve seat. Two additional

1

⁄

4

” (6mm) NPT connections with brass

plugs are to be provided on the opposite side of the metering ports

for use as drain connections. Drain connections and metering ports

are to be interchangeable for measurement flexibility when valves

are installed in tight locations. The valve body shall be ductile iron

with industrial standard grooved ends. Valve stem and plug disc

shall be bronze with ergonomically designed handwheel with multi-

turn handwheel adjustments. Sizes 2

1

⁄

2

” and 3” (65 and 80mm) -

five turns, 4” – 6” (100 – 150mm) - six turns, and 8” and 10” (200

and 250mm). Flange adaptors shall be supplied to prevent rotation.

The valve shall be a Watts Series CSM-91.

Pressure-Temperature

Grooved Ends Only

Maximum Working Pressure: 375psi (26.25 bar)

Maximum Temperature: 230°F (110°C)

Flange

Maximum Working Pressure:

Class 125: 175psi (12 bar)

Maximum Temperature: 230°F (110°C)

CSM-91

Nordel

®

is a registered trademark of DuPont Dow Elastomers.

Viton

®

is a registered trademark of DuPont Dow Elastomers.

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements,

please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials with-

out prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

Job Name –––––––––––––––––––––––––––––––––––––––––––

Contractor ––––––––––––––––––––––––––––––––––––––––––––

Job Location –––––––––––––––––––––––––––––––––––––––––

Approval –––––––––––––––––––––––––––––––––––––––––––––

Engineer –––––––––––––––––––––––––––––––––––––––––––––

Contractor’s P.O. No. ––––––––––––––––––––––––––––––––––

Approval –––––––––––––––––––––––––––––––––––––––––––––

Representative ––––––––––––––––––––––––––––––––––––––––