3 suction pressure requirements, 4 discharge pressure requirements, Suction pressure requirements – Pulsafeeder OMNI Series DC2-6 EN User Manual

Page 9: Discharge pressure requirements

5

5.3

Suction Pressure Requirements

Although OMNI

®

metering pumps have some suction lift capability, a flooded suction (i.e., suction

pressure higher than atmospheric pressure) is preferable whenever possible. The pump should be

located as close as possible to the suction side reservoir or fluid supply source.

For fluid with a vapor pressure of 5 psia or less (at operating temperature) the wet suction lift capability

is approximately ten (10) feet. If this requirement is not met, the pump will not provide reliable,

accurate flow. In suction lift conditions, the use of a foot valve is recommended at the lowest point of

the pickup tube or pipe. Pumps under suction lift conditions may require some liquid priming before

they will operate reliably.

5.4

Discharge Pressure Requirements

All OMNI

®

metering pumps are designed for continuous service at the rated discharge pressure. If

system suction pressure exceeds discharge pressure (a condition sometimes described as “pumping

downhill”), flow would be generated (siphoning) in addition to that caused by the pump. This results in

a reduction in accuracy and loss of control over the metering process. To prevent this flow-through

condition, the discharge pressure must exceed suction pressure by at least 0.35 Bar (5 psi). This can be

achieved where necessary by the installation of a backpressure valve in the discharge line. Conditions

where the actual discharge pressure exceeds the pump’s rating are to be avoided as they will cause

damage to the pump components.

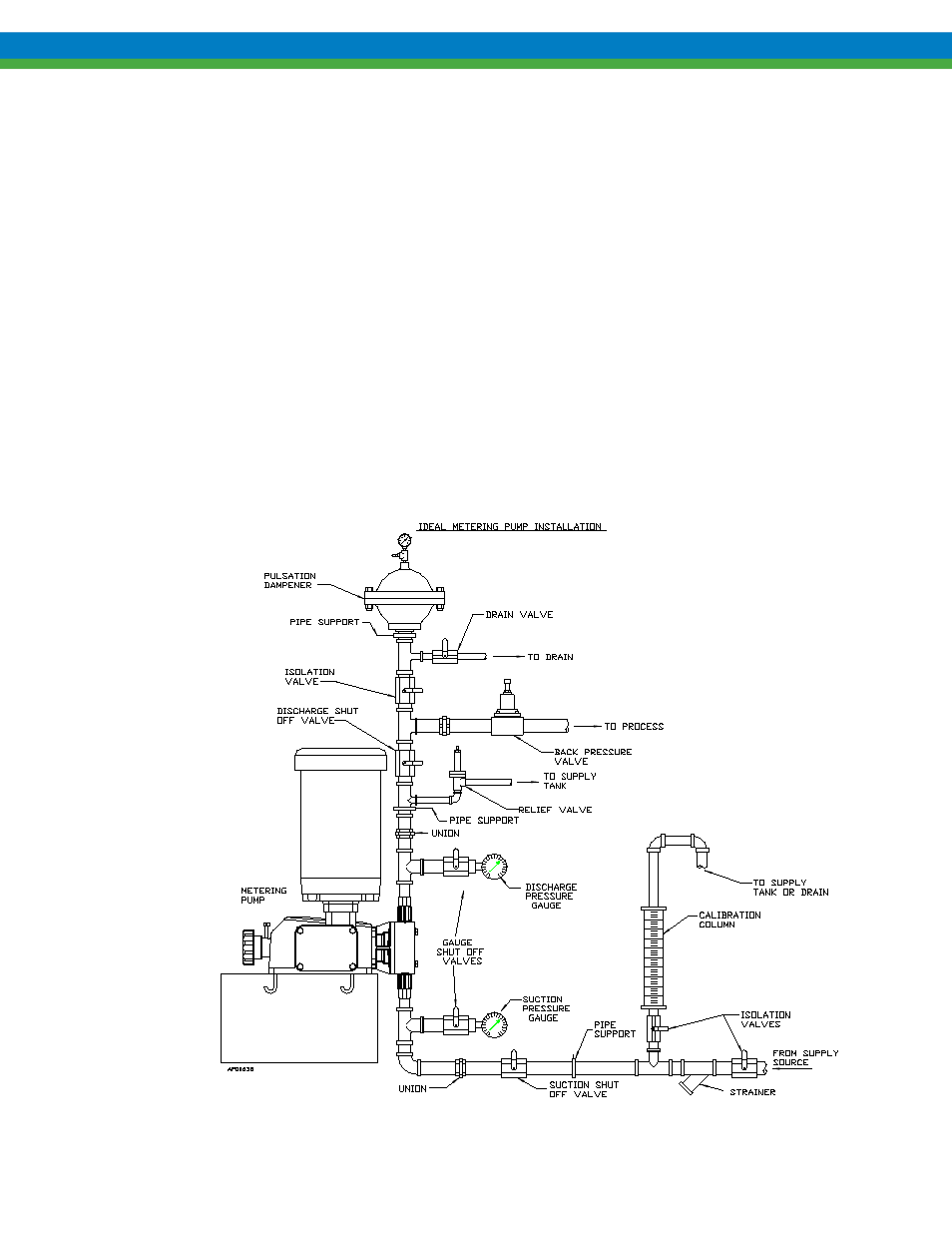

Figure 3, sample system configuration