Mc Leod 1400 Series Slip On Hydraulic Bearing User Manual

Mc Leod For the car

1

1400 Series Hydraulic Throw-Out Bearing Instructions

Congratulations! You have just purchased a precision engineered hydraulic throw out bearing

assembly. Properly installed this bearing assembly will provide proper clutch engagement and release

for many trouble free miles. Please review these instructions to become familiar with key parts along

with the proper installation procedures for this product. Prior to beginning this installation let’s be

certain you have the correct hydraulic throw out bearing assembly for your application. McLeod offers

two distinct types of hydraulic throw out bearing assemblies, the Slip-On style and the Bolt-On style. By

taking a few easy measurements on your bell housing to clutch release fingers you can easily determine if

this bearing is correct for your application.

McLeod Hydraulic Throw Out bearing assemblies will not work with counter weighted diaphragm style

pressure plates (Centerforce). If the weights are removed the bearing will function as designed.

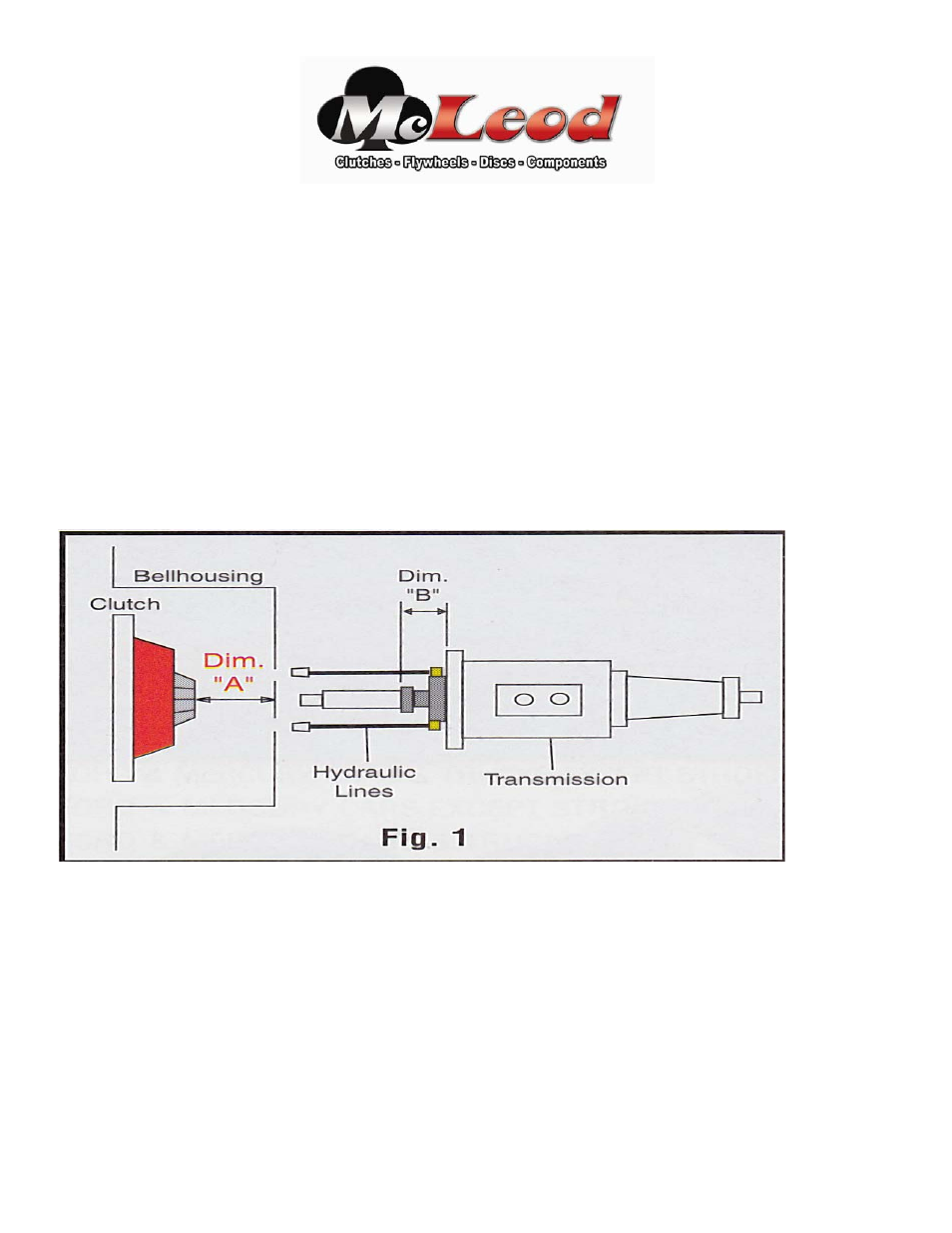

To Determine “Dimension A”: With the bell housing, flywheel, disc and pressure plate bolted to the

engine, measure the distance from the rear surface of the bell housing to the top of the release fingers on

the pressure plate. If this dimension measures less than 3” you should use a “Bolt-On” style hydraulic

throw out bearing assembly. If this dimension measures greater than 3” you should use a Slip-On style

hydraulic throw out bearing assembly.

Note: T-56 transmissions have a recessed front intermediate plate. Place a straight edge across the face of

the throw out bearing surface and measure to the front face of the front intermediate plate. The bearing

assembly on the T-56 is nested inside the front intermediate plate. This “B” dimension must be

determined to be certain you have the correct style bearing assembly. (Step 2).