Paasche Airbrush AB-PL User Manual

Fine art) airbrush

INSTRUCTIONS AND PARTS LIST AB-8/31/2011

Supersedes Instructions & Parts List AB-10/29/2008

WARNING: Spray materials may be harmful if inhaled or

allowed to come into contact with the skin or eyes. Consult

the product label and Material Safety Data Sheet supplied

for the spray material. Follow all safety precautions.

CAUTION: Well Ventilated Area Required to remove

fumes, dust or overspray. Secure airhose to Airbrush

with V-62 Wrench for safety and to prevent air leaks.

M a x i m u m A i r P r e s s u r e 5 0 P . S . I .

AB

(Fine Art) Airbrush

Customer Note: New “AB” Airbrushes are factory inspected for

immediate use.

The “AB” Airbrush maintenance and replacement parts

instructions are for Airbrushes that have been used extensively

and require refurbishing.

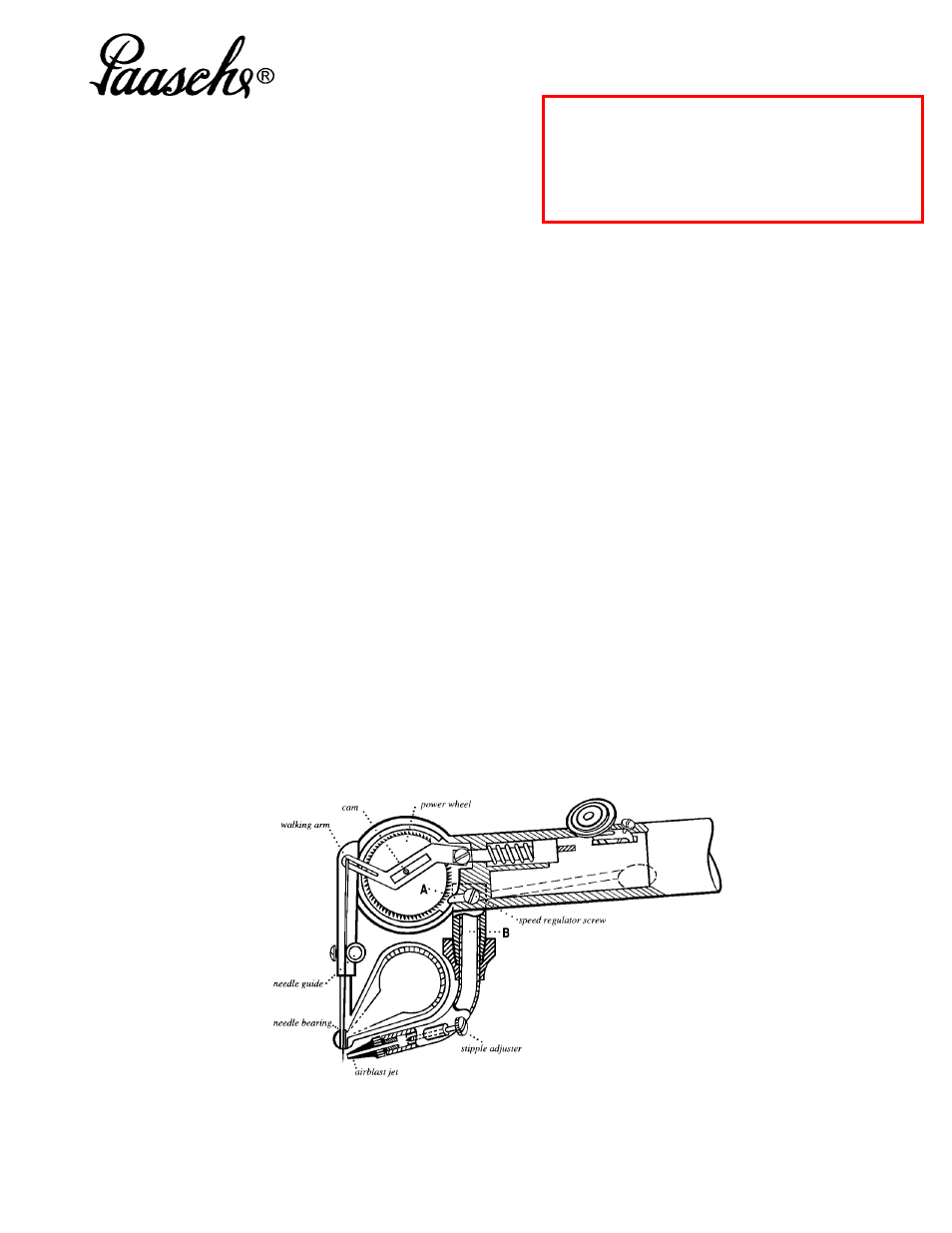

HOW THE AB WORKS:

The illustration below gives you an idea what is going

on inside your AB. As the finger lever is pressed down, air

from your compressor is channeled from the air valve

through the body of the airbrush. The airstream then

splits, and part of the air is pushed across the edge of the

power wheel ( A ) while the rest goes through the airblast

tube ( B ). The edge of the power wheel is serrated, so

that the air pushing against it causes the power wheel to

spin. You will notice that the shaft on which the power

wheel rotates passes through a slot in the walking arm.

Actually, the portion of the shaft which rides in the slot is

offset from center, so that with a cam like action the

spinning of the power wheel causes the walking arm (and

thus the needle) to oscillate back and forth. The speed

regulator screw controls the speed of the power wheel

(and thus the walking arm and needle) by regulating the

volume of air pushing against the power wheel.

When you press down on the finger lever, you let air

into the airbrush and start the needle moving back and

forth. Then as you pull back on the finger lever, the

walking arm is pushed forward, and in turn the oscillating

needle is pushed into the stream of air coming from the

airblast tube. Thousands of times per minute, the needle

retracts into the needle bearing, picks up a coating of color

and then moves forward, drawing the color out of the

bearing and into the airstream, where the color is blown off

the needle and onto the surface you are painting. The

needle is tapered, so that as you pull back farther on the

finger lever, a thicker portion of the needle is exposed to

the airstream and a wider band of color is formed.

A line is thus formed by the action of the needle passing

back and forth in front of the stream of air coming from the

airblast jet, and you control the thickness of that line with

the finger lever. But the quality of that line and the ease

with which you can control it are affected by three other

controls, all of which regulate the volume or the pressure

of the air passing through the airbrush.

METHODS OF CONTROL:

As mentioned before, the speed regulator screw

controls the volume of air hitting the power wheel, and so

controls the speed of the needle. The faster the needle

moves, the more color is being blown onto the surface you

are painting during a given length of time. If you want to

form a thin line, you can do so by having the needle

moving at a high speed and sweeping the airbrush very

quickly over your work, or by having the needle oscillating

much slower and moving the airbrush more slowly.

Obviously the second method offers the most control and

is a major advantage of using the Paasche AB.

There is another method of controlling the speed of the

needle, however, and that is by adjusting the pressure of

the air coming into the airbrush. In this case, if you have

the speed regulator screw turned wide open (counter-

clockwise) with low air pressure (8-15 P.S.I.) from your air

source, the power wheel and needle will move slowly. But

the needle will also move slowly using a high air pressure

(25-35 P.S.I.) with the speed screw turned almost closed

(clockwise).

A comparable situation exists for the flow of air through

the airblast tube. The stipple adjuster screw restricts the

airflow through the airblast jet and across the needle.

When the air is almost closed off, a grainy or stippling

effect is created. But the same effect happens with the

stipple adjuster wide open using a very low air pressure.

As you can see, there are many different combinations

of settings for these three controls (the speed regulator,

the stipple adjuster, and the air pressure) each

combination producing a characteristic effect, both in spray

pattern and handling of the airbrush.

Printed in the U.S.A.

Paasche Airbrush Company

4311 North Normandy Avenue

Chicago, IL 60634-1395

Phone: 773-867-9191 • Fax: 773-867-9198

Website: paascheairbrush.com

E-Mail: [email protected]

All AB needles should have a bow in them in

order to be held securely by the needle

guide and enter the needle bearing properly.