Sk series, General pump – General Pump SK Owner Manual User Manual

Page 13

GENERAL PUMP

A member of the Interpump Group

SK SERIES

Page 13

9.6 Filtration

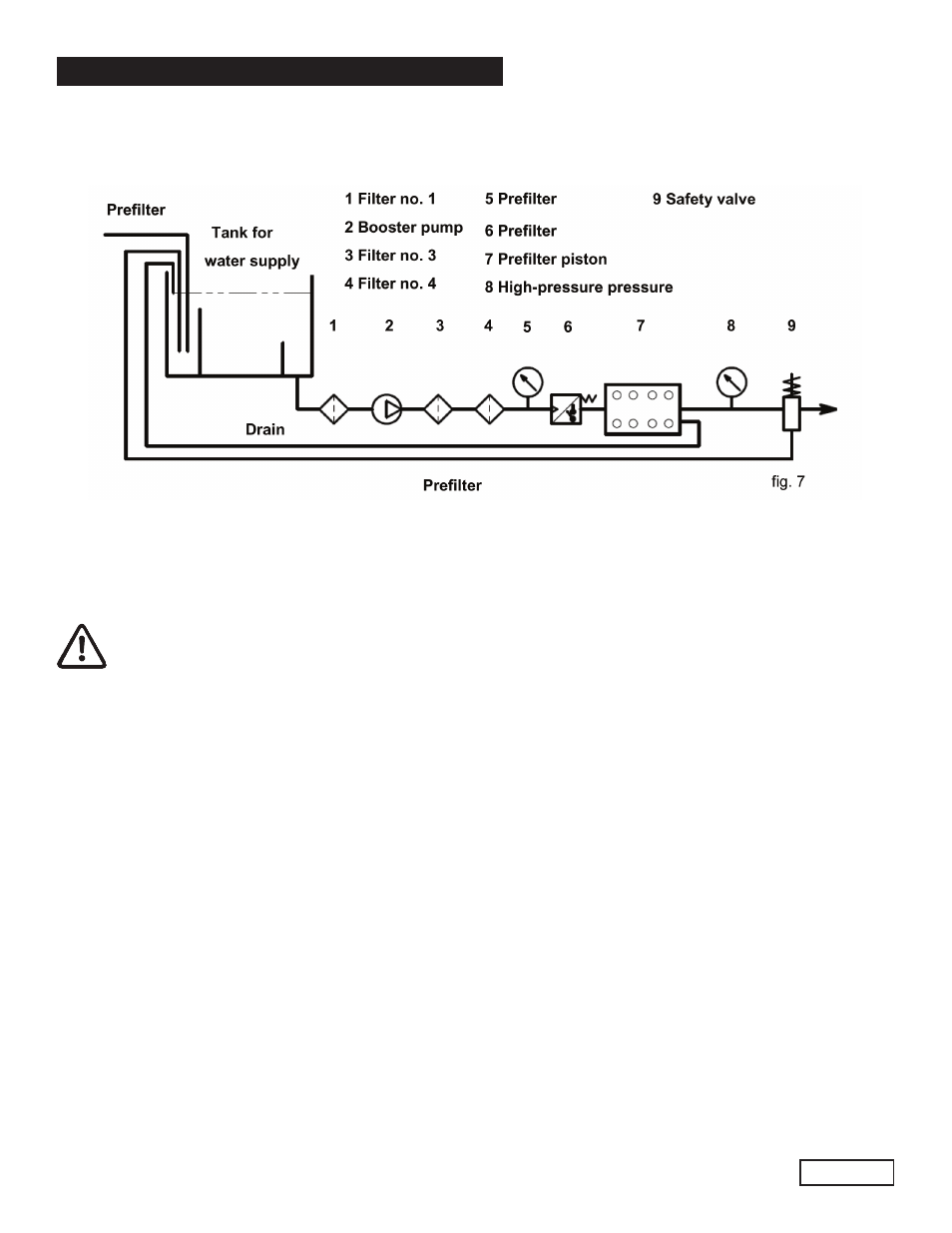

The level of filtration permitted for this series of pumps must be maximum 20 µm (micron). Normally this is obtained by a

battery of at least three filters, positioned as shown in fig. 7.

The filters must be installed as close as possible to the pump. They must be easily accessible for inspection amd must

have the following specifications:

Filter number 1: 250 µm

Filter number 3: 100 µm

Filter number 4: 20 µm

In order to guarantee correct pump operation, it is important to plan periodical cleaning of the filter

depending on actual pump usage, water quality and actual clogging conditions.

To guarantee the supply pressure required (see 9.4) install a pressure switch.

9.7 Outlet Line

To obtain a correct delivery line, please comply with the following installation instructions:

1. The internal diameter of the pump must allow to guarantee correct fluid speed; see digram in paragraph 9.8

2. The first section of the hose connected to the pump must be flexible in order to isolate pump vibrations

from the rest of the system.

3. Use high pressure hoses and fittings that guarantee wide safety margins in any working condition.

4. Install a safety valve on the delivery line.

5. Use pressure switches suitable for the pulsating loads typical of plunger pumps.

6. In the design phase, take into proper account the pressure drop along the line, since this causes a reduction in

usage pressure with respect to the value measured at the pump.

7. If the pump pulsations are harmful for particular applications, install an appropriately sized pulsation dampener on

the outlet line.

Ref 300792 Rev.C

06-12