Lk series, General pump – General Pump LK Owner Manual User Manual

Page 16

GENERAL PUMP

A member of the Interpump Group

LK SERIES

Page 16

10. START-UP AND OPERATION

10.1 Preliminary Inspections

Before Start-up Be sure that:

The inlet line is connected and up to pressure (see Chapter 9) the pump must NEVER run dry.

1. The suction line must be perfectly airtight.

2. All the On-Off valves between the pump and the feeding source are completely open. The outlet line must

discharge freely in order to allow the air in the pump to be expulsed easily, thus facilitating pump priming.

3. All inlet/outlet connections and fittings must be correctly tightened.

4. Coupling tolerances on the pump/transmission axis (half-joint misalignment, Cardan inclination, belt

tightening, etc.) must remain within the limits indicated by the transmission Manufacturer.

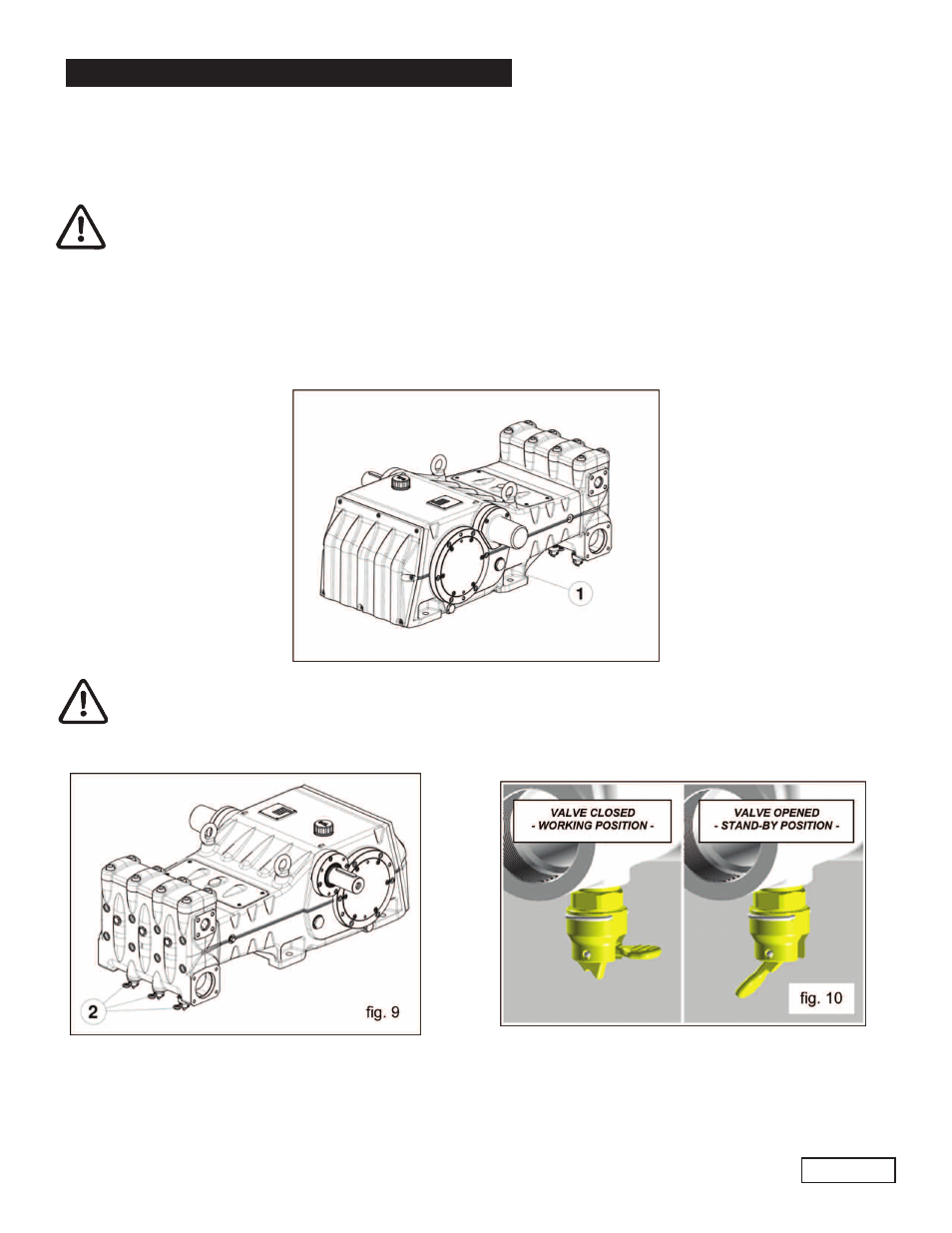

5. The pump’s oil level must be verified using the oil level lights (position 1, fig 8).

If the pump has been in storage or inactive for a lengthy period, the inlet valves must be restored to their

proper working condition by opening the three valve lifters (pos. 2, fig. 9). Make sure the valves are closed

again before starting the pump. For the “working” and “stop” positions see fig. 10.

fig. 8