Lk series, General pump – General Pump LK Owner Manual User Manual

Page 12

GENERAL PUMP

A member of the Interpump Group

LK SERIES

Page 12

The power take-off can be taken from either side of the pump. Generally the pump is supplied with the PTO shank for

the right-hand side (see fig. 6). To get the PTO from the left-hand side, she shaft end cover must be taken off and

remounted on the right hand side of the pump (see 2.1.1 in the repair manual). Vice-versa, the lug must be removed

from the right-hand side and inserted in the shank of the left-hand side.

9.3 Hydraulic Connections

In order to isolate the system from the vibrations produced by the pump, we recommend building the first section of the

hose near the pump (both for intake and delivery) with flexible hose. The solidity of the intake section must allow to avoid

deformation caused by the depressurization produced by the pump.

9.4 Pump Supply

LK pumps must always be installed under positive suction head, i.e. it must receive water falling from above or from a

supply under pressure, and it must never “suck” water from a lower level. The pumps can tolerate minimum water heads

of 1 meter. However, to obtain the best volumetric output and, especially, to prevent cavitation, the available net positive

suction head (NPSH avail), measured at the inlet flange at the head, must be greater than or equal to the values below:

9.5 Inlet Line

For the pump to function well, the inlet line must have the following characteristics:

1. Minimum internal diameter as indicated in the diagram in paragraph 9.8, and in any case equal or

greater than that of the pump head. Along the duct, avoid localized diameter reductions that may cause

pressure drops with subsequent cavitation. Absolutely avoid 90

0

elbows, connections with other hoses,

bottlenecks, counter-slopes, upside down “U” shaped curves, “T” connections.

2. The selected lay-out must allow to avoid cavitation.

3. It should be perfectly airtight, and built in a way that guarantees perfect sealing over time.

4. Avoid pump emptying when stopping (even partial emptying).

5. Do not use hydraulic-type fittings, 3 or 4 way fittings, adapters, etc., since they may hinder the pump’s

performance.

6. Do not install Venturi tubes or injectors for detergent intake.

7. Avoid the use of standing valves, check valves, or any other type of one-way valves.

8. Do not connect the by-pass line from the valve directly to the pump suction line.

9. Provide appropriate baffle plates inside the tank in order to avoid water flows coming from both the

by-pass and feeding lines may create turbulence near the tank’s outlet port.

10. Make sure that the suction line is perfectly clean inside before connecting it to the pump.

11. The pressure gauge for checking booster pressure must be installed near the plunger pump’s outlet

port, and always downstream of the filters.

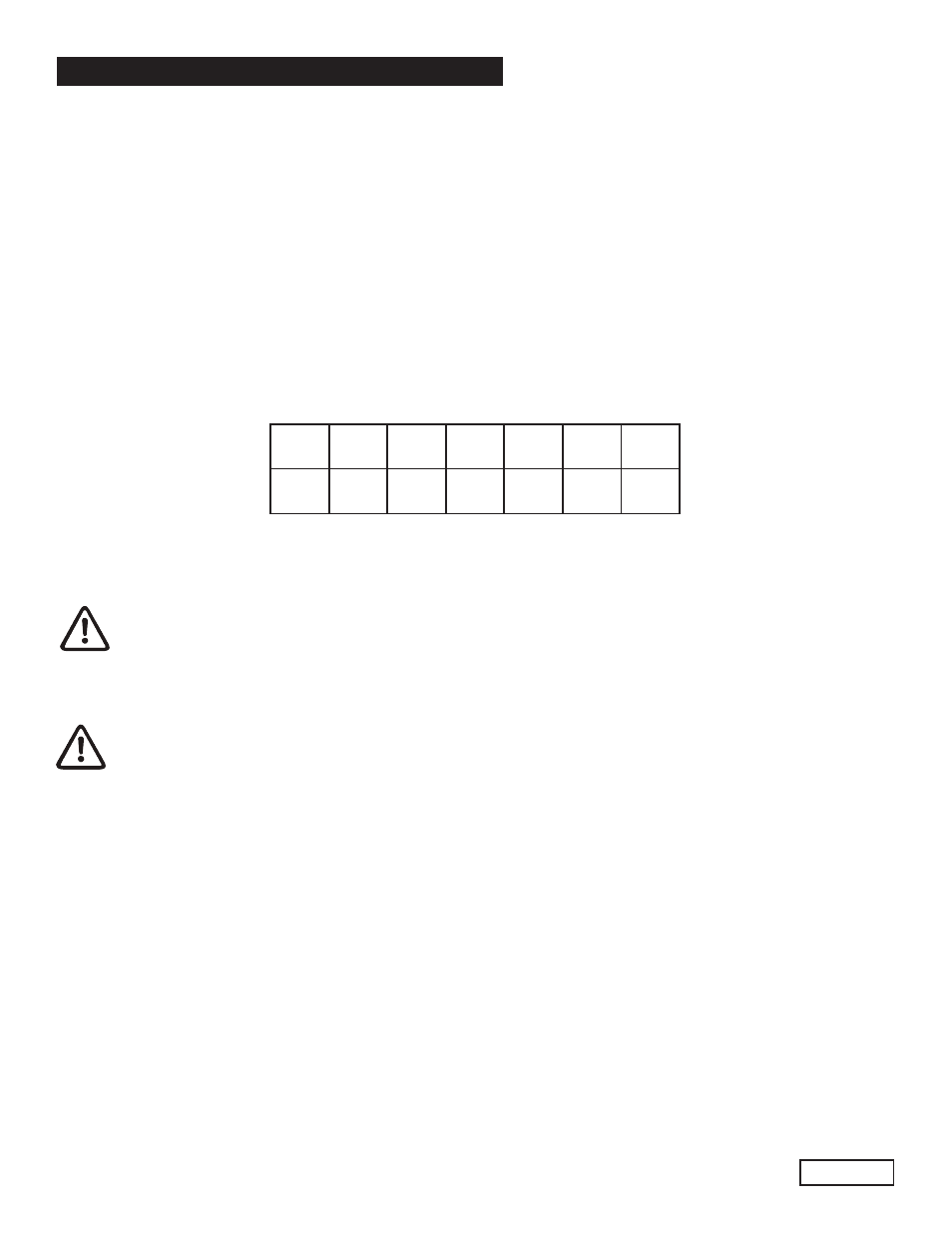

LK36

LK40

LK45

LK50

LK55

LK60

NPSH

r

(m)

4

4.5

5.5

6.5

7.5

5

For pumps of greater capacity, i.e. LK50, LK55 and LK60, supply under pressure from a booster pump is strongly recom-

mended to avoid cavitation, due to the geometry of the hydraulic part and the high flow rates. The booster pump must

have a flow rate of at least double that of the rated flow rate of the plunger pump, and a pressure of between 30 and 44

PSI (2 and 3 bar). These supply conditions must be respected for any and all working systems.

Booster start-up must always be started before the plunger pump. In order to protect the pump, we

advise installing a pressure switch on the supply line downstream of the filters.