Kf series, General pump – General Pump KF Owner Manual User Manual

Page 14

GENERAL PUMP

A member of the Interpump Group

KF SERIES

Page 14

The new roller bearings can be mounted at room

temperature with a press; it is necessary to hold them on

the side surface of the ring nuts with suitable rings. The

driving operation can be facilitated by heating the parts

at a temperature between 250-300oF, making sure that the

ring nuts are correctly fitted in their seats.

Note: Take care not to invert the components of the 2

bearings (outer ring nut of bearing 1 instead of the one of

bearing 2...).

To maintain the right axial load, the shim package has to

be calculated again as follows:

A) Install the crankshaft into the crankcase making sure

that the PTO end comes out on the correct side.

B) Fit the motor side flange on the crankcase with

special attention to the seal lip as indicated on point

11.1.2.

C) Position the sight glass side flange using the 3

screws M6 x 16 until the crankshaft cannot be

turned freely by hand.

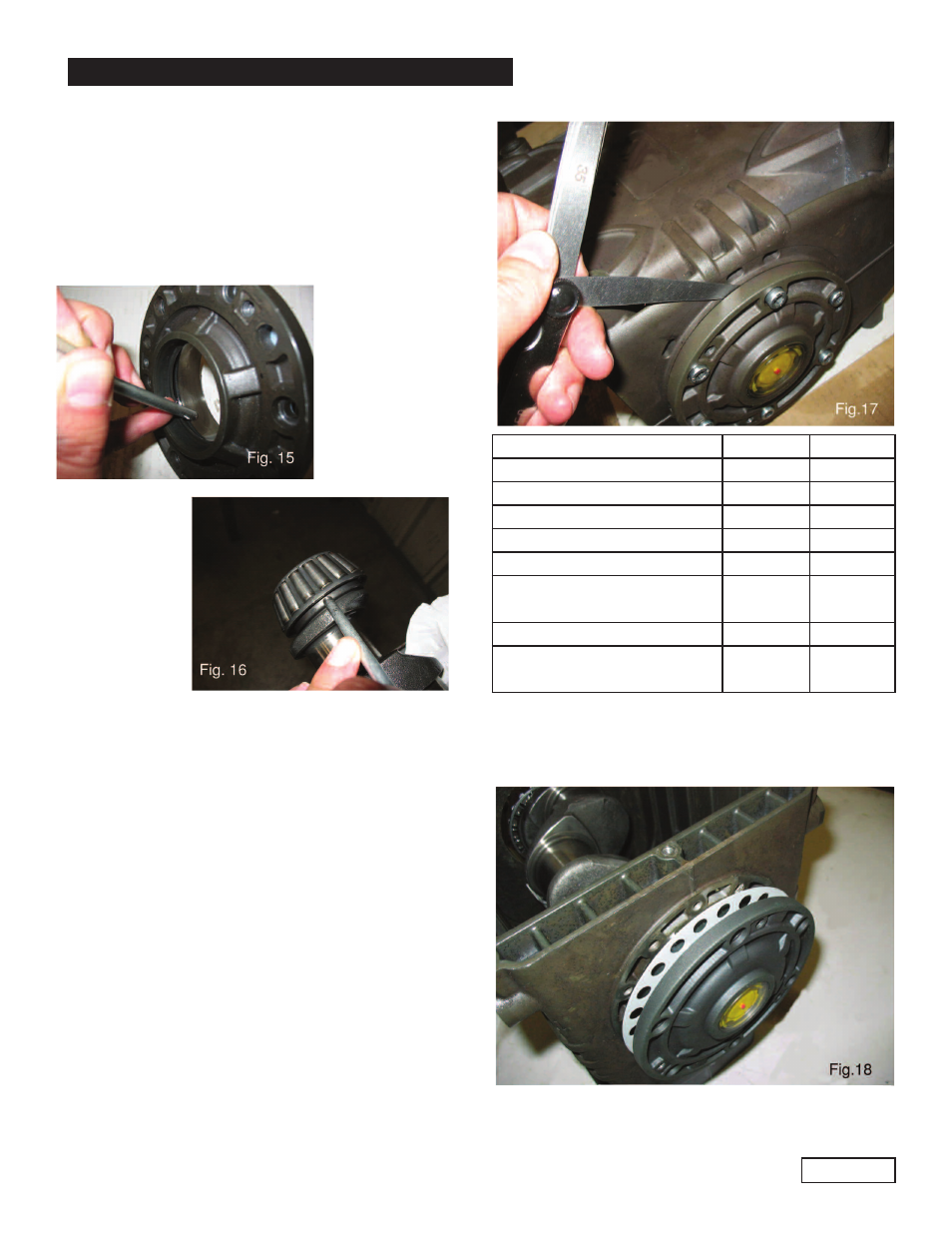

D) By means of a thickness gauge (see Fig. 17)

determine the shim set as indicated in the table

below.

Measure

Shim Type # of Pieces

From: 0.05 a: 0.10

From: 1.00 a: 0.20

0.1

1

From: 0.21 a: 0.30

0.1

2

From: 0.31 a: 0.35

0.25

1

From: 0.36 a: 0.45

0.35

1

From: 0.46 a: 0.55

0.35

0.10

1

1

From: 0.56 a: 0.60

0.25

2

From: 0.61 a: 0.70

1.35

0.25

1

1

E)

Fit the shims under the sight glass cover

tightening it on the crankcase with the screws,

checking that the stall torque is between 4 Nm and

6 Nm.

F)

If the torque is correct, connect the rods to the

crankshaft, otherwise, calculate the shims again

as per point “C”.

11.1.4 Disassembling / reassembling of the crankshaft

with replacement of the bearings

After disassembling the side covers, as indicated in 11.1.1,

remove the outer ring nut of the bearings from their covers

and the inner ring nut, together with the remaining part of

the bearing, from the 2 shaft ends by means of a standard

pin extractor or similar tool. See fig. 15 and 16.