Perma Pure Baldwin-Series M325 User Manual

Page 5

Section C: Principle of Operation

5

C:

P

RINCIPLE OF

O

PERATION

Thank you for purchasing a Perma Pure Baldwin™-Series Thermo-Electric Cooler. This

Modular Series features a unique slim design leaving additional space to install or access

other sample conditioning system components. A unique drop-down door on the Modular

Series provides easy access to electronic boards and the power supply. All electronic

boards (control, relay, and display) are mounted on the door for easy access.

The process of sampling combustion product stack gas or exhaust from internal combustion

engines requires a method to remove the moisture from the sample, without removing the

gas components of interest. The Baldwin-Series cooler is an ideal way to decrease the dew

point of combustion gases to a repeatable, stable, constant low dewpoint. The Baldwin

cooler prevents water condensation in sample pre-filters, sample pumps, and gas analyzers.

For gas analyzers where water vapor is an interferant, a stable, repeatable dewpoint

becomes a part of the gas analyzer performance specification. Baldwin-Series coolers

provide this constant low water concentration, resulting in an accurate component gas

measurement.

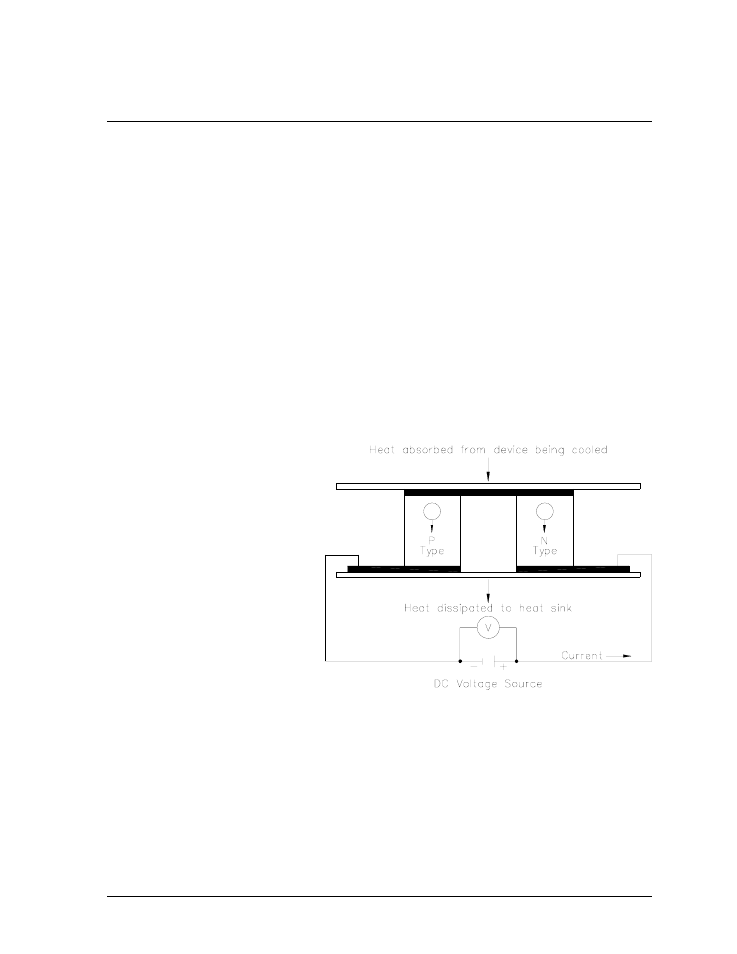

All Baldwin-Series coolers use thermo-electric elements (Peltiers) to cool the sample gas to

the desired dew point temperature. A thermo-electric cooler is best illustrated as a small

heat pump with no moving parts. The Peltiers operate on direct current and may be used

for heating or cooling by reversing

the direction of current flow. This

is achieved by moving heat from

one side of the module to the

other with current flow and the

laws of thermodynamics. A typical

single stage Peltier (Figure 1)

consists of two ceramic plates with

p- and n-type semiconductor

material (bismuth telluride)

between the plates. The elements

of semiconductor material are

connected electrically in series

and thermally in parallel.

When a positive DC voltage is

applied to the n-type thermo-

electric element, electrons pass from

the p- to the n-type thermo-electric

element and the cold side temperature will decrease as heat is absorbed. The heat

absorption (cooling) is proportional to the current and the number of thermo-electric

elements. This heat is transferred to the hot side of the Peltier element where it is

dissipated into the heat sink and surrounding environment.

Baldwin-Series Thermo-Electric Coolers remove the moisture from the sample gas by

cooling the gas as it passes through a laminar impinger (heat exchanger). A diagram

showing the gas flow path through an impinger is shown in the Appendix. The heat

exchanger, made of 316L stainless steel, Durinert

®

(a corrosion-resistant inert coating over

Figure 1: Thermo-electric element (Peltier)