3 minimum flow values -10, Refer to sections 5-3 and 5-4 f, W listed in table 5-3 – Brooks Instrument 5866M User Manual

Page 33: W listed in table 5-3 go to, Alues listed in table 5-3, W listed in table 5-3 the v, W listed in table 5-3 decrease the

Brooks Instrument Model 5866 Pressure Controller

5-10

B. Adjustment procedure, Normally Open (N.O.) control valve

Refer to Figure 5-4 for spacer locations and nomenclature for the Normally

Open (N.O.) type control valve. Refer to Section 7, spare parts for the

spacer part numbers and the spacer kit part number. The valve clearance

determines the maximum space between the orifice (12) and the valve

seat (11). If the valve clearance is too small the controller will not achieve

full flow. If the valve clearance is too large, the control valve will not close

properly.

The air gap is the space between the plunger (16) and insert (17) in the

control valve. The air gap determines the magnetic force available to

operate the valve. If the air gap is too large the magnetic force will be

insufficient and the valve will not close. If the air gap is too small the valve

will have insufficient travel and the valve will not close.

1. Make the bench testing set up as shown in Figure 5-2. Disconnect the

valve connector from the side of the Model 5866 and connect it to the

variable power supply and volt meter as shown. Polarity is not important.

2. Remove gas pressure. Disassemble the control valve following the

procedure given in Section 5-3, above. Note the orifice size, which is

marked on the orifice face. Referring to Figure 5-4, note the number,

location and thickness of all spacers (9 and 10).

3. Reassemble the valve and set the variable voltage power supply to zero

Volts.

4. Apply 5 psig to the inlet of the Model 5866 if equipped with 0-1 bar

transducer. Apply 10 psig for instruments equipped with other

transducers.

5. Observe the flow and compare it to the values listed in Table 5-3.

6. If the observed flow is greater that the listed value for the orifice size

that is installed then go to Step 8.

7. If the flow is less than the minimum flow increase the valve clearance

by adding a large 0.005" spacer (10) above the spring spacer (19) and

repeat Steps 5 and 6.

8. Apply 18 Volts to the valve using the variable power supply and observe

the flow.

Note: The maximum allowable leak through in controllers with an

elastomer valve seat is 2% of the values listed in Table 5-3, (multiply by

0.02). The maximum allowable leak through for controllers with a metal

or Teflon valve seat is 8% of the values listed in Table 5-3, (multiply by

0.08).

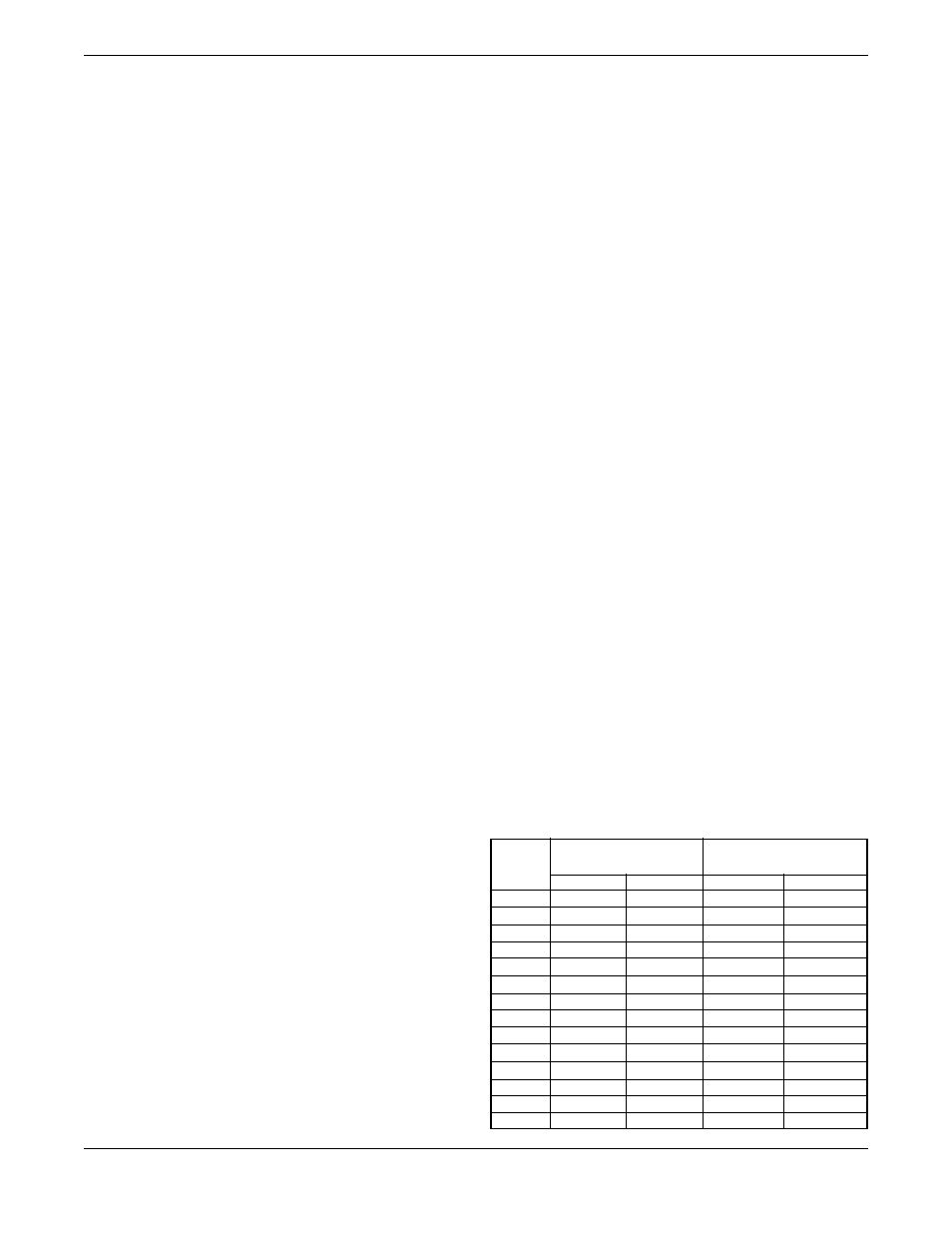

Table 5-3. Minimum Flow Values.

Orifice

Minimum Flow

Minimum Flow

Size

with 10 psig pressure

with 5 psig pressure

(inches)

sccm (0°C) sccm (70°F) sccm (0°C)

sccm (70°F)

.001

5.3

5.7

3.9

4.0

.002

12.5

13.5

8.8

9.5

.003

39.2

42.2

27.7

29.8

.004

82.5

88.9

58.5

62.9

.007

374

403

264

285

.010

748

806

529

570

.014

1,364

1,470

964

1,039

.020

2,673

2,879

1,890

2,040

.032

6,490

7,000

4,590

4,940

.048

13,000

14,000

9,180

9,890

.062

22,000

23,700

15,500

16,800

.078

31,900

34,400

22,500

24,300

.093

42,500

45,800

30,000

32,400

.120

69,300

74,700

49,000

52,800