Waterpik Technologies pool/spa heater User Manual

Page 18

Page 16

side of the valve. The pressure will be zero when the heater

is not running. When the heater is operating the manifold

gas pressure should be 4.0" wc for natural gas and 9.0" wc

for LP within .2" wc. To adjust the manifold gas pressure,

first remove the slotted cap next to the inlet pressure port

on the inlet side of the gas valve. Under the slotted cap is a

slotted plastic screw which increases the manifold pressure

when turned clockwise and decreases the manifold pressure

when turned counterclockwise. After measurements, and

adjustments if necessary, have been made, make sure to

replace the 1/8" NPT gas valve plugs on the inlet and

manifold pressure ports, and the cap on the manifold

pressure adjustment screw. It is extremely important to

replace these parts before leaving the installation. Failure to

do so can result in damage to property or injury or death.

With the heater firing, the pressure must be within the

range shown in Table 7. Also check the pressure with the

heater off.

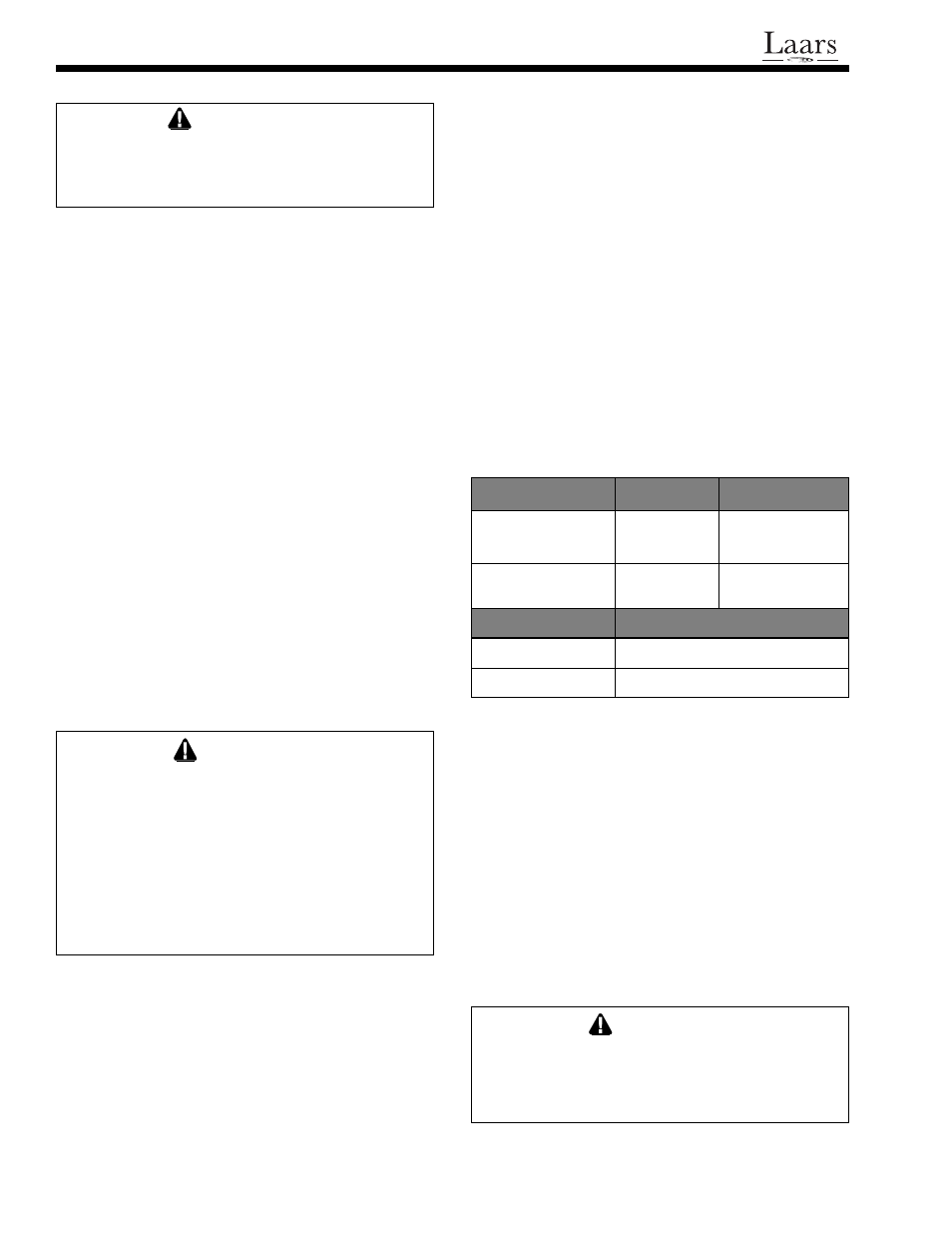

Table 7. Gas Supply Pressure Requirements

Supply Pressure

Minimum

Maximum

Natural Gas

6.0 Inches WC

11.0 Inches WC

(1.5 kPa)

(2.8 kPa)

LP Gas

10.5 Inches WC

14.0 Inches WC

(2.7 kPa)

(3.5 kPa)

Manifold Pressure Nominal

Natural Gas

4.0 Inches WC (1.0 kPa)

LP Gas

9.0 Inches WC (2.3 kPa)

2J-4. Adjustment of Water Pressure

Switch

If the heater is installed in line with a two speed

pump, the pressure switch MUST be adjusted to prevent

the heater from firing on low-speed or low-flow pump

operation. The pressure switch is preset at the factory for

normal pool installations. Do not adjust it unless the

heater's water connections are more than three feet above

or below the pool surface. If they are not in this range, the

pressure switch must be adjusted. This can be done in the

field if the water connections are no more than six feet

above the pool surface or no more than ten feet below it.

For other situations, contact a Waterpik Technologies

representative.

The pressure switch should be adjusted to turn

the heater off when the pump is off. Setting

the switch to close at too low of a flow can

damage the appliance.

Do not operate this heater outdoors at

temperatures below 20 degrees Fahrenheit

(°F) (-7 degrees Celsius [°C]).

2J-2. Start-up

Confirm that pool water is flowing normally through

the pool system and equipment. Start the heater in

accordance with the Operating Instructions section of this

manual, with particular attention to the lighting and

shutdown instructions and temperature control operation.

The heater may not start on the first try. Air in the

gas line or other start-up situations may cause it to recycle.

It will lock out if ignition is not achieved in three attempts.

On the LX model heater, to provide three additional

attempts, press and release the mode button until the

indicator on the LCD screen aligns with "OFF". Now press

and release the button again until the indicator on the

LCD screen aligns with the desired setting, either "POOL"

or "SPA".

To reset the cycle on the model LT press and release

the mode button until the indicator lights for the "SPA"

and "POOL" settings are off. Then press and release it

again until the indicator light for the desired setting is

back on..

When the heater starts, immediately feel the outlet

header of the heater to confirm that there is adequate water

flow. The header should not be hot. Normally, water

temperature will rise only a few degrees as it passes

through the heater, and a hot header or pipe indicates

low water flow.

When the heater is fired for the first time, the

combustion chamber refractory binder material

is driven out by the heat of the flame. White

smoke and/or sharp odors may be emitted

from the vent during this period. Do not inhale

combustion product fumes at any time, and

especially when these fumes are being

emitted. This burn-in period will last only a

few minutes.

2J-3. Gas Pressure

Confirm that gas supply pressure is correct. If the

gas supply pressure is less than required, check for

undersized pipe between the meter and the heater, a

restrictive fitting, or an undersized gas meter. Gas supply

pressures to the heater, when it is operating, are listed in

Table 7.

The manifold pressure may be checked by

connecting a manometer to the pressure port on the outlet

WARNING

WARNING

CAUTION