Smith Cast Iron Boilers Series 28A User Manual

Page 9

Page 9

SERIES 28A BOILER INSTALLATION AND OPERATION INSTRUCTIONS

5.

Insert the large port connector with its steel inner

ring into the upper port.

6.

Insert the two round port connectors into the lower

ports.

NOTE: Apply the spray adhesive supplied with the

boiler to the port recess to hold the port connector

in place if necessary.

7.

Select the correct intermediate section and carefully

move it into place against the back section, Figure

4.

CAUTION: Any steam uptake and heater sections

must be located as shown in Table 3. Failure to

comply with this caution may result in poor boiler

performance and prevent the jacket from fitting!

Only one intermediate section with an external leg

boss has been included. It should be located toward

the front of the boiler for optional low water cutoff

use. See Table 3.

NOTE: A putty knife or similar tool can be used to

hold the port connectors in place while the

intermediate section is positioned. It must be

removed before the sections make contact or the

port connector will be damaged resulting in a leak!

8.

Insert the four draw rods through the casting

bosses. Thread nuts onto one end of the rods. Place

washers on the other end of the rods before

threading nuts onto them. Snug the nuts finger tight.

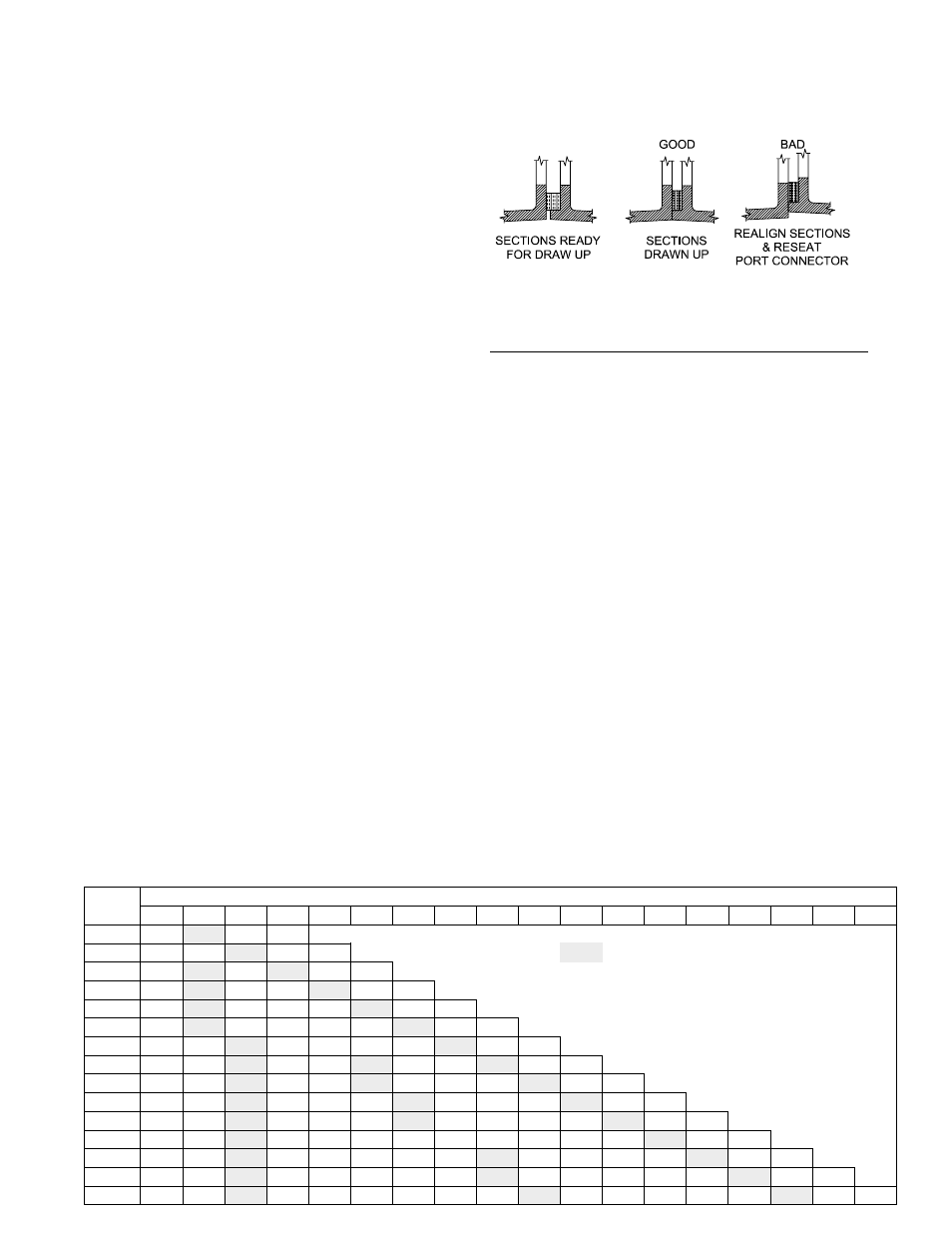

Use a spirit level to ensure that the first two sections

are plumb and properly aligned, Figure 6. Check the

rope to insure that it’s properly positioned. Once the

sections are plumb and the rope and por t

connectors are properly positioned follow the torque

sequence shown in Table 4.

Figure 6 - Section Alignment

Table 4 - Section Torque Sequence

Step

Rod Position

Torque

ft lbs

Nm

1

Upper Right

25

34

2

Lower Left

25

34

3

Lower Right

25

34

4

Upper Left

10

14

5

Upper Right

50

68

6

Lower Left

50

68

7

Lower Right

50

68

8

Upper Right

75

102

9

Lower Left

75

102

10

Lower Right

75

102

11

Upper Left

30

42

12

Upper Right

125

169

13

Lower Left

125

169

14

Lower Right

125

169

15

Upper Right

125

169

16

Upper Left

40

54

NOTE: With these initial torques the sections may

not be metal to metal, which is acceptable. If any of

the ports leak during the hydrostatic test the torque

can be increased to 200 ft lbs,

271 Nm on the upper

right rod. The torque on the lower left and right rods

can be increased to 150 ft lbs,

203 Nm. Once the

sections are metal to metal additional torque will not

improve the seal.

Boiler

Section Location Numbered From Front To Back

Model

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

28A-4

F

T

H

B

F

Front Section

28A-5

F

H

T

H

B

T

Intermediate Section w/ 5" Tapping & Boss

28A-6

F

T

H

T

H

B

H

Intermediate Section w/ Heater Opening

28A-7

F

T

H

P

T

H

B

P

Intermediate Section, Plain

28A-8

F

T

H

P

H

T

H

B

B

Back Section

28A-9

F

T

H

P

H

P

T

H

B

28A-10

F

H

T

H

P

H

P

T

H

B

28A-11

F

H

T

H

P

T

P

T

H

B

28A-12

F

H

T

H

P

T

H

P

H

T

H

B

28A-13

F

H

T

H

P

H

T

P

P

H

T

H

B

28A-14

F

H

T

H

P

H

T

H

P

H

P

T

H

B

28A-15

F

H

T

H

P

H

P

T

H

P

H

P

T

H

B

28A-16

F

H

T

H

P

H

P

H

T

H

P

H

P

T

H

B

28A-17

F

H

T

H

P

H

P

H

T

H

P

H

P

H

T

H

B

28A-18

F

H

T

H

P

H

P

H

P

T

H

P

H

P

H

T

H

B

Table 3 - Section Locations