Speed range bearing sleeve, Headstock gearing, Ram ways – Southbend South Bend SB1027 User Manual

Page 47: Head & ram rack & pinion gear

For Machines Mfg. Since 8/09

Model SB1027

-45-

M A I N T E N A N C E

Speed Range Bearing Sleeve

Oil Type ...... Mobil Vactra 2 or ISO 68 Equivalent

Oil Amount .......................................... Fill Oil Cup

Check/Add Frequency ............40 hrs. of Operation

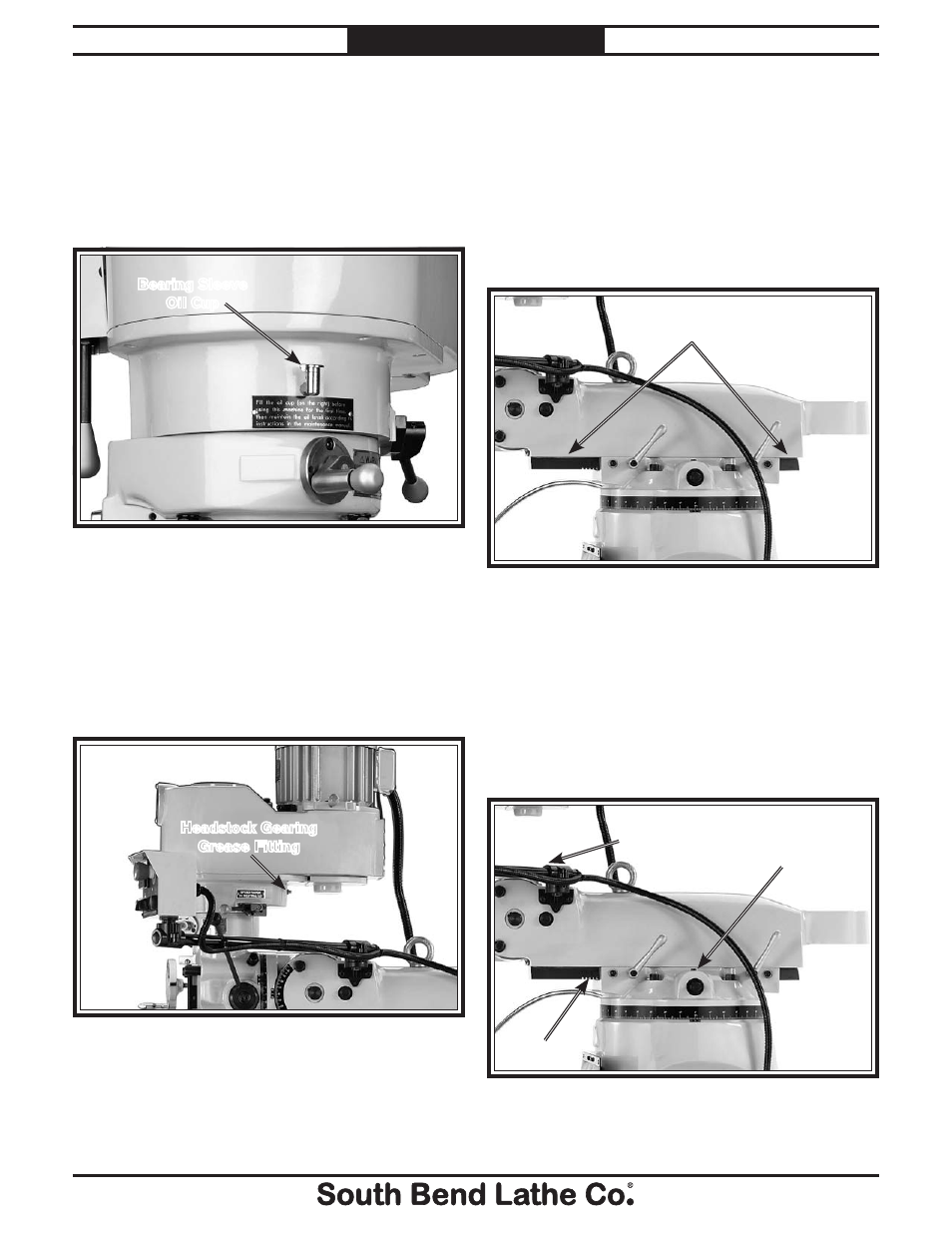

Lift the oil cup cap shown in Figure 48 to fill the

oil cup with lubricant.

Headstock Gearing

Grease Type .........................NLGI 2 or Equivalent

Grease Amount ...........Two Pumps of Grease Gun

Check/Add Frequency ............40 hrs. of Operation

Add two pumps from a grease gun to the grease

fitting for the mill that is shown in Figure 49.

Figure 49. Headstock gearing grease fitting.

Headstock Gearing

Grease Fitting

Ram Ways

Oil Type ...... Mobil Vactra 2 or ISO 68 Equivalent

Oil Amount ............................................. Thin Coat

Check/Add Frequency ............40 hrs. of Operation

Move the ram back and forth as necessary

to access the full length of the ways (see

Figure 50), then use a clean shop rag to apply a

thin coat of lubricant.

Figure 50. Exposing the ram ways for lubrication.

Ram Ways

Head & Ram Rack & Pinion Gear

The interaction between the cast iron surfaces

of these devices (see Figure 51) produces a dry

powder that provides an adequate lubrication.

Do not apply any other lubricant which could

produce a stiff compound that may interfere with

smooth movement.

Figure 51. Locations of head and ram rack and pinion

gears.

Ram Rack

Ram Pinion

Gear

Head Rack

& Pinion Gear

Figure 48. Speed range bearing sleeve.

Bearing Sleeve

Oil Cup