Lifting & moving – Southbend South Bend SB1027 User Manual

Page 18

-16-

For Machines Mfg. Since 8/09

Model SB1027

P R E P A R A T I O N

Lifting & Moving

This machine and its

parts are heavy! Serious

personal injury may occur

if safe moving methods are

not used. To reduce the

risk of a lifting or dropping

injury, ask others for help

and use power equipment.

The method of lifting and moving the mill

described below requires at least two other

people for assistance, and a forklift with two

lifting web straps rated for at least 3000 lbs.

each.

Important: Before lifting the mill, make sure the

four turret lock bolts (two on either side of the

ram) are torqued to 47 ft/lbs.

To lift and move the mill:

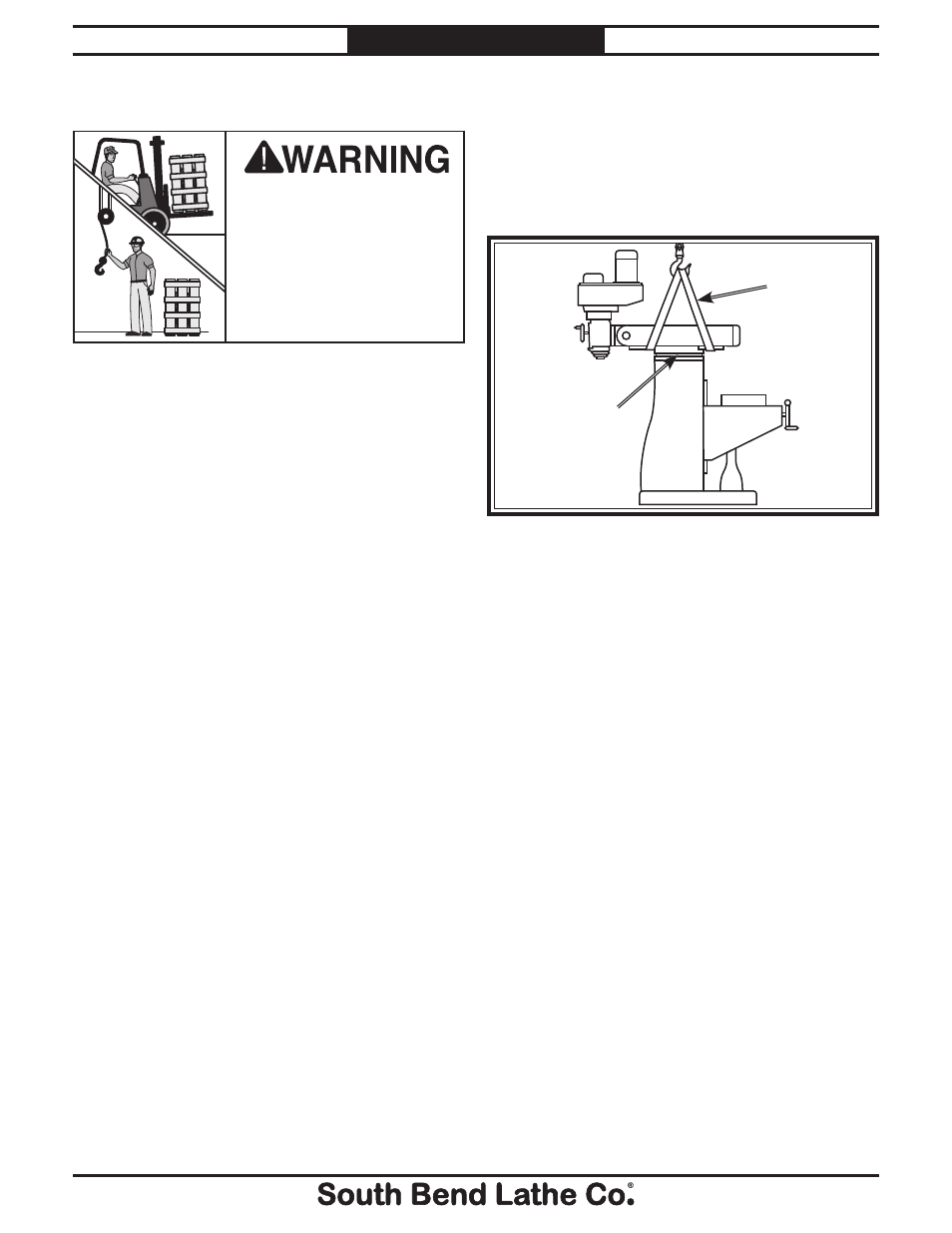

1. Swing the ram around 180° from the position

that it was shipped in, then rotate the

head upright, as illustrated in Figure 5

(refer to Ram Movement on Page 33 and

Headstock Movement on Page 29 for

detailed instructions).

Note: After re-positioning the ram and

headstock, make sure they are locked in

place to prevent unexpected movement

during lifting and moving.

2. Place the lifting web straps under the ram

and connect them to the safety hook, as

illustrated in Figure 5.

Note: Place padding between the straps and the

mill to protect the ram and ways, and to

keep from cutting the lifting straps.

Figure 5. Lifting the mill using web straps.

Lifting

Web Straps

Turret

Lock Bolts

3. Unbolt the mill from the shipping pallet.

4. With your assistants steadying the load to

keep it from swaying, lift the mill a couple of

inches.

— If the mill tips to one side, lower it to the

ground and adjust the ram or table to

balance the load. Make sure to re-tighten

the lock levers and bolts before lifting the

mill again.

— If the mill lifts evenly, continue to move it

to its permanent location.