SEAL 44/62 User Manual

Page 24

22

Application Processes

6.4 Laminating and adhesive coating (Decaling)

This process involves sandwiching an image between either a hot or cold laminate on the

face of the image and a pressure-sensitive adhesive on the rear. This process can be

used to create self-adhesive images for mounting down onto various substrates.

Once the machine reaches the operating temperature, the top roller may be raised and

webbed as per the following diagrams. Refer to the Temperature/Speed chart on the front

side of the machine and in the manual for settings and recommended film combinations

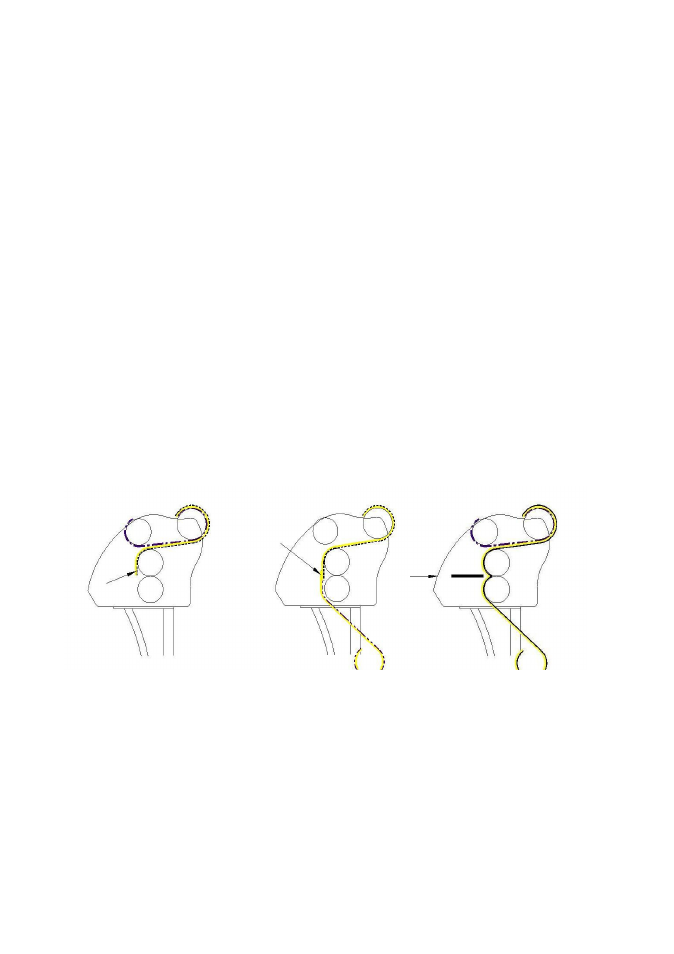

Decal process with liner;

Over-laminate on top and Pressure-sensitive mounting on bottom.

Linered films:

Pull the film down from the top unwind position.

1. Split the film from the release liner, flip the liner back (fig.21) and pull the film evenly

across the face of the rollers.

2. Place the wind-up idler into the brackets.

3. Place the scrape core on the idler and the top roller.

4. Attach the liner onto the scrape core, using a piece of tape.

5. Push the films all the way through the machine, using the leaderboard.

6. Replace the infeed table.

7. ALWAYS INSTALL THE IMAGE GUIDE.

Figure 21

Figure 22

Figure 23

YOU ARE NOW READY TO FEED IMAGES.