Mounting, Motor.below – Woodstock W1681 User Manual

Page 10

-8-

W1681 Buffing Assembly

SE

TU

P

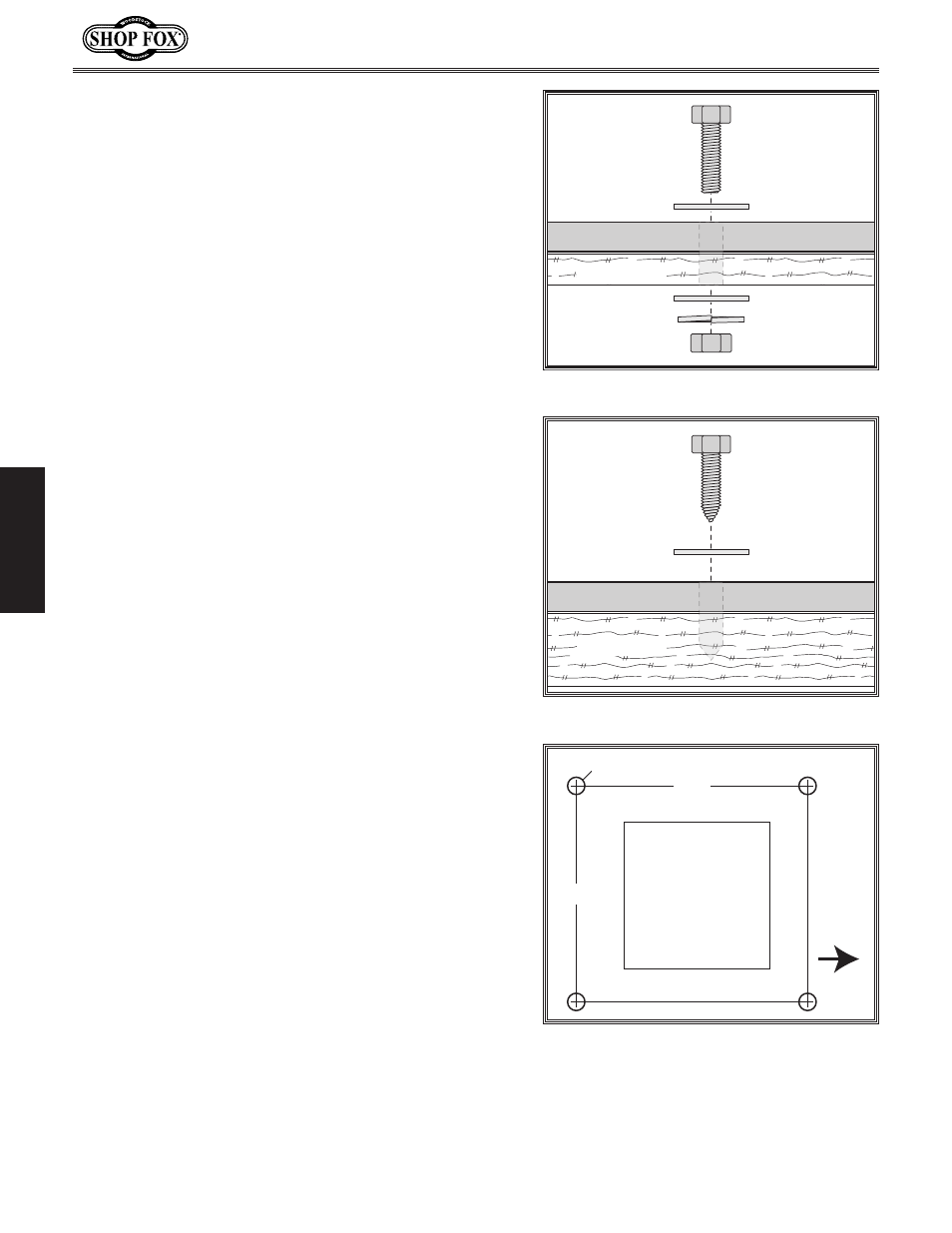

The strongest bench mounting option is a "Through

Mount" where holes are drilled all the way through the

workbench, and hex bolts, washers, and hex nuts are

used to secure the drill press to the workbench.

Another option for mounting is a "Direct Mount" where the

machine is simply secured to the workbench with a lag

screw.

The Model W1681 is designed to mount to a bench top

using (4)

5

⁄

16

" diameter lag bolts or through bolts, as

shown in

Figures.2.& 3.

The motor must be mounted either directly below or

behind the Buffing assembly. If the motor is mounted

below the buffing assembly, a hole must be cut in the

bench to allow passage of the V-belt between the buffing

assembly and the motor. If the motor is mounted behind

the buffing assembly, no hole in the bench is needed

because the V-belt will connect to the motor through the

rear casting of the buffing assembly body.

The buffing assembly must be attached to a stable

workbench capable of handling the rigors of a motor

driven machine. Determine if you will be mounting the

motor below or behind the buffing assembly.

Motor.Below

1. Position the buffing assembly on the workbench in

the desired position. Mark the four mounting hole

locations onto the workbench, as shown in

Figure.4.

2. Trace around the open area on the inside, bottom

edge of the buffing assembly. This will be the hole

for the V-belt passage to the motor mount beneath.

3. Remove the buffing assembly from the workbench.

Using a jig saw and drill, cut out the V-belt

passage hole and drill the mounting holes into the

workbench.

4. Place the buffing assembly over the mounting holes

in the workbench. Using (4)

5

⁄

16

" diameter lag bolts

or through bolts, attach the buffing assembly to the

workbench, making sure that it is secure.

Mounting

Machine Base

Workbench

Bolt

Flat Washer

Flat Washer

Lock Washer

Hex Nut

Figure.2. Example of a through mount.

Machine Base

Workbench

Lag Screw

Flat Washer

Figure.3. Example of a direct mount.

4-3/4"

4-1/2"

3/8" Dia.

Front

Figure.4. Mounting bolt layout.

Provided for

reference only.

For best results,

use your machine

as a template for

marking holes