Irflow – Goodman Mfg SS-GME8 User Manual

Page 5

4

www.goodmanmfg.com

SS-GME8

SS-GME8

www.goodmanmfg.com

5

P

roduct

S

PecificationS

P

roduct

S

PecificationS

a

irFlow

d

ata

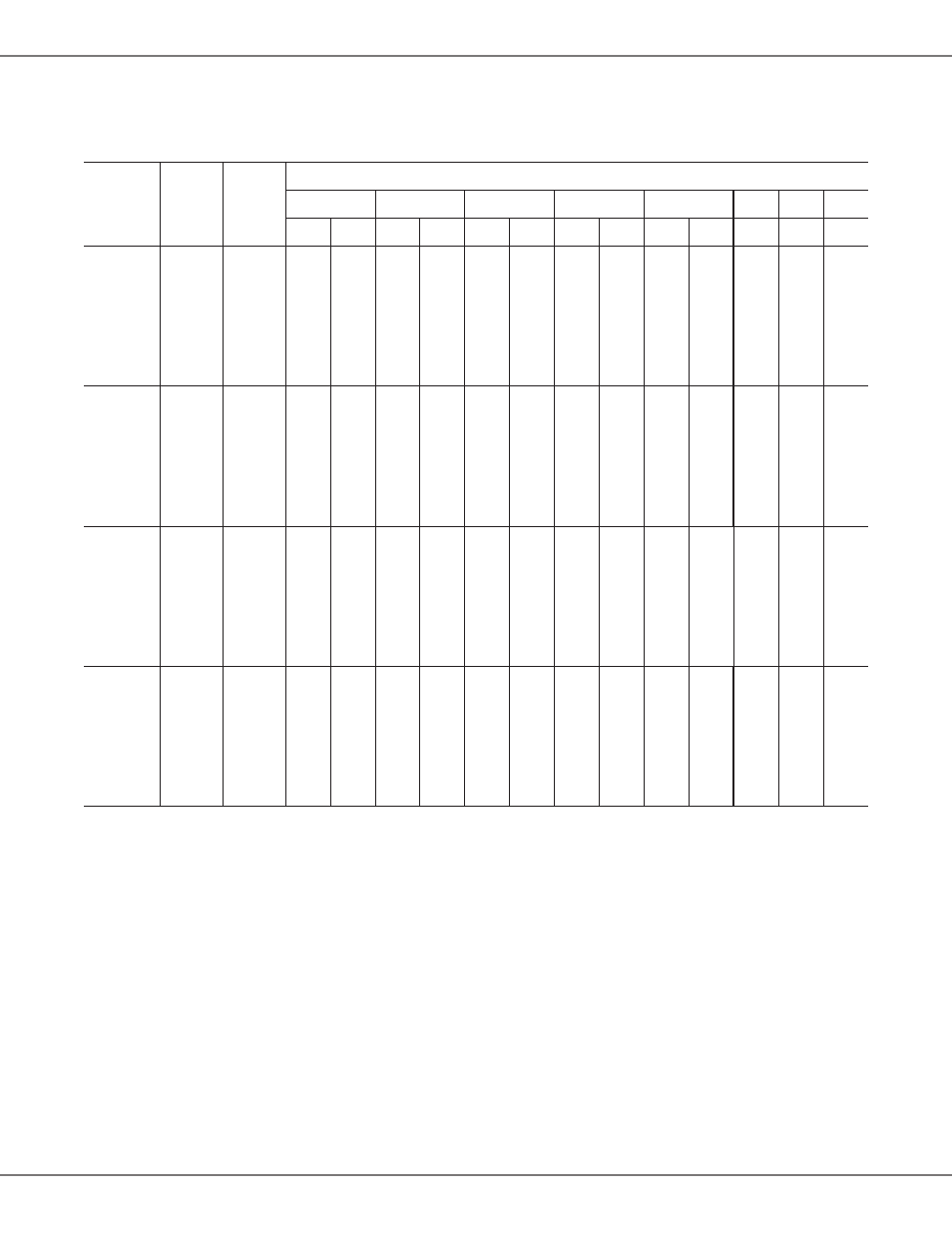

(CFM & Temperature Rise vs. External Static Pressure)

Model

Motor

Speed

Tons

AC¹

External Static Pressure, (Inches Water Column)

0.1

0.2

0.3

0.4

0.5

0.6

0.7

0.8

CFM

Rise

CFM

Rise

CFM

Rise

CFM

Rise

CFM

Rise

CFM

CFM

CFM

GME8

0603B*B

T1

1½

875

---

793

---

736

---

674

---

592

---

556

509

460

T2

2

1,032

43

965

46

914

49

861

---

810

---

756

712

659

T3

2½

1,217

37

1,153

39

1,098

40

1,051

42

1,009

44

964

918

877

T4

3

1,365

33

1,313

34

1,268

35

1,221

36

1,172

38

1,129 1,086 1,054

T5

3½

1,549

29

1,505

30

1,460

30

1,420

31

1,378

32

1,350 1,305 1,268

GME8

0805C*B

T1

2½

1,268

47

1,198

49

1,151

51

1,092

54

1,041

57

988

932

883

T2

3

1,362

44

1,305

45

1,261

47

1,212

49

1,170

51

1,121 1,074 1,021

T3

3½

1,576

38

1,519

39

1,473

40

1,426

42

1,398

42

1,341 1,290 1,252

T4

4

1,755

---

1,711

35

1,657

36

1,627

36

1,579

38

1,548 1,502 1,463

T5

5

2,183

---

2,128

---

2,094

---

2,060

---

2,014

---

1,992 1,944 1,847

GME8

0805D*A

T1

3½

1,524

39

1,479

40

1,439

41

1,388

43

1,343

44

1,281 1,243 1,190

T2

4

1,683

35

1,646

36

1,607

37

1,569

38

1,531

39

1,488 1,441 1,395

T3

4

1,884

31

1,832

32

1,849

32

1,765

34

1,724

34

1,692 1,661 1,626

T4

4

1,951

30

1,904

31

1,879

32

1,842

32

1,803

33

1,768 1,734 1,687

T5

5

2,036

29

2,010

29

1,977

30

1,947

30

1,923

31

1,888 1,844 1,816

GME8

1005C*B

T1

3

1,466

51

1,415

52

1,357

55

1,306

57

1,248

59

1,202 1,144 1,088

T2

3½

1,642

45

1,596

46

1,552

48

1,499

49

1,449

51

1,388 1,352 1,306

T3

4

1,750

42

1,750

42

1,707

43

1,667

44

1,610

46

1,574 1,531 1,486

T4

4

1,870

40

1,805

41

1,782

42

1,737

43

1,701

44

1,656 1,606 1,571

T5

5

2,297

---

2,297

---

2,224

---

2,106

35

2,014

37

1,896 1,813 1,669

¹ @ 0.5” ESP

Notes

• CFM in chart is without filter(s). Filters do not ship with this furnace, but must be provided by the install-

er. If the furnace requires two return filters, this chart assumes both filters are installed.

• All furnaces ship as high-speed cooling and medium-speed heating. Installer must adjust blower cooling and heating speed as needed.

• For most jobs, about 375 - 400 CFM per ton when cooling is desirable.

• INSTALLATION IS TO BE ADJUSTED TO OBTAIN TEMPERATURE RISE WITHIN THE RANGE SPECIFIED ON THE RATING PLATE.

• This chart is for information only. For satisfactory operation, external static pressure should not exceed value shown on the rating plate.

• At higher altitudes, a properly derated unit will have approximately the same temperature rise at a particular CFM, while ESP at the CFM will be lower.

• Factory Motor Speed Setting: T1 = 1st Stage Ht, T2 = 2nd Stage Ht, T5 = Cooling

• Temperature rise data is based on second-stage heat. First-stage heat is 75% of rise indicated above.