1077 actuator, Instruction manual – Fisher 1077 User Manual

Page 3

1077 Actuator

Instruction Manual

Form 5605

March 2007

3

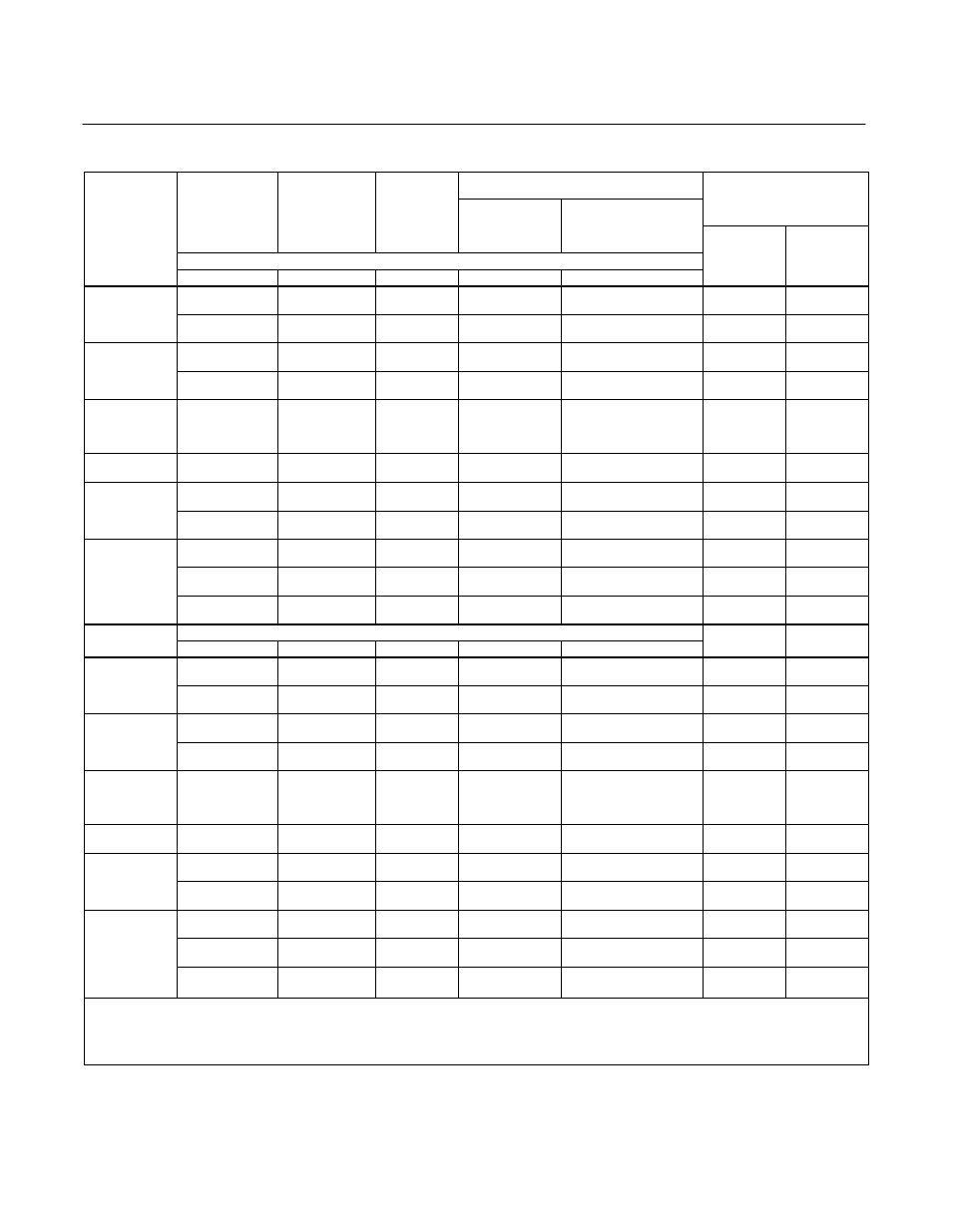

Table 2. Actuator Size Selection

ACCEPTABLE

MAXIMUM

HAND

WHEEL-RIM FORCE

HANDWHEEL TURNS

REQUIRED FOR FULL VALVE

ACTUATOR

ACCEPTABLE

VALVE

SHAFT

MAXIMUM

ALLOWABLE

TORQUE

(1)

HAND-

WHEEL

DIAMETER

To Produce

Maximum

To Produce Torque Lower

Than Maximum Allowable

REQUIRED FOR FULL VALVE

DISC OR BALL ROTATION

ACTUATOR

SIZE

SHAFT

DIAMETER

TORQUE

(1)

DIAMETER

Maximum

Allowable Torque

Than Maximum Allowable

Shaft

Torque

60-Degree

90-Degree

Metric Units

60-Degree

Rotation

90-Degree

Rotation

mm

N

Sm

mm

N

N

Rotation

Rotation

0-KE

12.7

15.9

58

138

152

152

129

307

Torque Req’d

(N

Sm) B 0.4572

4

6

0-KE

19.1

22.2 & 25.4

240

271

(2)

203

(4)

203

396

445

(3)

Torque Req’d

(N

Sm) B 0.6096

4

6

2-KE

22.2 & 25.4

468

203

485

Torque Req’d

(N

Sm) B 0.9652

6-1/2

9-1/2

2-KE

31.8

38.1

678

(2)

678

(2)

305

305

467

(3)

467

(3)

Torque Req’d

(N

Sm) B 1.4478

6-1/2

9-1/2

6-KE

31.8

38.1

44.5

50.8

1110

1360

1360

(2)

1360

(2)

610

610

610

610

365

445

445

(3)

445

(3)

Torque Req’d

(N

Sm) B 3.0480

6-1/2

10

7-KE

44.5

50.8

2260

(2)

2260

(2)

762

762

440

(3)

440

(3)

Torque Req’d

(N

Sm) B 5.1435

9

13-1/2

9-KE

44.5

50.8

2260

2260

762

762

436

436

Torque Req’d

(N

Sm) B 6.096

10-1/2

16

9-KE

63.5

3390

(2)

914

463

(3)

Torque Req’d

(N

Sm) B 7.3152

10-1/2

16

63.5

6305

431

431

Torque Req’d

(N

Sm) B 15.476

48

72

10-KE:6

76.2

6780

(2)

610

310

(3)

Torque Req’d

(N

Sm) B 21.848

48

72

88.9

6780

(2)

610

310

(3)

Torque Req’d

(N

Sm) B 21.848

48

72

U.S. Units

Inches

Inch-Pounds

Inches

Pounds

Pounds

0-KE

1/2

5/8

515

1225

6

6

29

69

Torque Req’d

(In.-Lb.)

B 18.00

4

6

0-KE

3/4

7/8 & 1

2120

2400

(2)

8

(4)

8

89

100

(3)

Torque Req’d

(In.-Lb.)

B 24.00

4

6

2-KE

7/8 & 1

4140

8

109

Torque Req’d

(In.-Lb.)

B 38.00

6-1/2

9-1/2

2-KE

1-1/4

1-1/2

6000

(2)

6000

(2)

12

12

105

(3)

105

(3)

Torque Req’d

(In.-Lb.)

B 57.00

6-1/2

9-1/2

6-KE

1-1/4

1-1/2

9820

12,000

24

24

82

100

Torque Req’d

6-1/2

10

6-KE

1-1/2

1-3/4

2

12,000

12,000

(2)

12,000

(2)

24

24

24

100

100

(3)

100

(3)

Torque Req d

(In.-Lb.)

B 120.00

6-1/2

10

7-KE

1-3/4

2

20,000

(2)

20,000

(2)

30

30

99

(3)

99

(3)

Torque Req’d

(In.-Lb.)

B 202.50

9

13-1/2

9-KE

1-3/4

2

23,524

23,524

30

30

98

98

Torque Req’d

(In.-Lb.)

B 240.00

10-1/2

16

9-KE

2-1/2

30,000

(2)

36

104

(3)

Torque Req’d

(In.-Lb.)

B 288.00

10-1/2

16

2-1/2

55,762

16

97

Torque Req’d

(In.-Lb.)

B 612.00

48

72

10-KE:6

3

60,000

(2)

24

69

(3)

Torque Req’d

(In.-Lb.)

B 864

48

72

3-1/2

60,000

(2)

24

69

(3)

Torque Req’d

(In.-Lb.)

B 864

48

72

1. Values shown are the maximum allowable torque of a splined valve shaft except where indicated. Without regard to the shaft, maximum allowable torque output is 271 N

S

m (2400

inch-pounds) for the size 0-KE actuator, 678 N

S

m (6000 inch-pounds) for the size 2-KE actuator, 1360 N

S

m (12,000 inch-pounds) for the size 6-KE actuator, 2260 N

S

m (20,000

inch-pounds) for the size 7-KE actuator, 3390 N

S

m (30,000 inch-pounds) for the size 9-KE actuator, and 6780 N

S

m (60,000 inch-pounds) for the size 10-KE:6 actuator.

2. Limited to this value by the maximum allowable output torque of the actuator.

3. Wheel-rim force required to produce maximum actuator output torque.

4. Handwheel is 152 mm (6-inch) diameter for keyed-shaft constructions.